$35.95

Yale Forklift D807 (ERP1.6-2.0ATF) Service Manual – PDF DOWNLOAD

Yale Forklift D807 (ERP1.6-2.0ATF) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift D807 (ERP1.6-2.0ATF) Service Manual – PDF DOWNLOAD

Language : English

Pages : 740

Downloadable : Yes

File Type : PDF

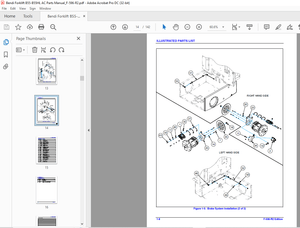

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift D807 (ERP1.6-2.0ATF) Service Manual – PDF DOWNLOAD

524150790-2100YRM0103-(03-2007)-UK-EN 1

toc 1

Tilt Cylinders 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Tilt Cylinder Repair 5

Remove 5

Disassemble 5

Clean 5

Assemble 6

Tilt Cylinders With O-Ring or Single-Lip Seals 6

Tilt Cylinders 7

Install 8

Tilt Cylinder Leak Check 10

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 11

Torque Specifications 11

Piston Rod Nut 11

Retainer 11

Troubleshooting 12

tables 1

Table 1 Movement Rates (Maximum) for Tilt Cylinders 10

524150797-8000YRM0231-(03-2020)-UK-EN 17

General 21

Threaded Fasteners 21

Nomenclature, Threads 21

Strength Identification 22

Cotter (Split) Pins 23

Fastener Torque Tables 28

Conversion Table 30

524158040-2240YRM0001-(03-2020)-UK-EN 37

General 41

Battery Type 41

Lead-Acid Batteries 41

Lithium-Ion Batteries 42

Specific Gravity 42

Chemical Reaction in a Cell 42

Electrical Terms 44

Battery Selection 44

Battery Voltage 45

Battery as a Counterweight 46

Battery Ratings 46

Kilowatt-Hours 46

Battery Maintenance 46

Safety Procedures 46

Maintenance Records 47

New Battery 47

Cleaning Battery 47

Adding Water to Battery 49

Hydrometer 50

Battery Temperature 51

Charging Battery 52

Types of Battery Charges 52

Methods of Charging 54

Troubleshooting Charger 54

Knowing When Battery Is Fully Charged 55

Where to Charge Batteries 55

Equipment Needed 55

Battery Connectors 56

Battery Care 56

Troubleshooting 58

524158890-4000YRM0521-(03-2006)-UK-EN 63

toc 63

Mast 63

Safety Precautions Maintenance and Repair 64

General 67

Description and Operation 67

Carriages 67

Mast Mounts 69

Two-Stage Mast, Limited Free-Lift (LFL) 70

Description and Operation 70

Two-Stage Mast, Full Free-Lift (FFL) 72

Description and Operation 72

Three-Stage Mast, Full Free-Lift (FFL) 74

Description and Operation 74

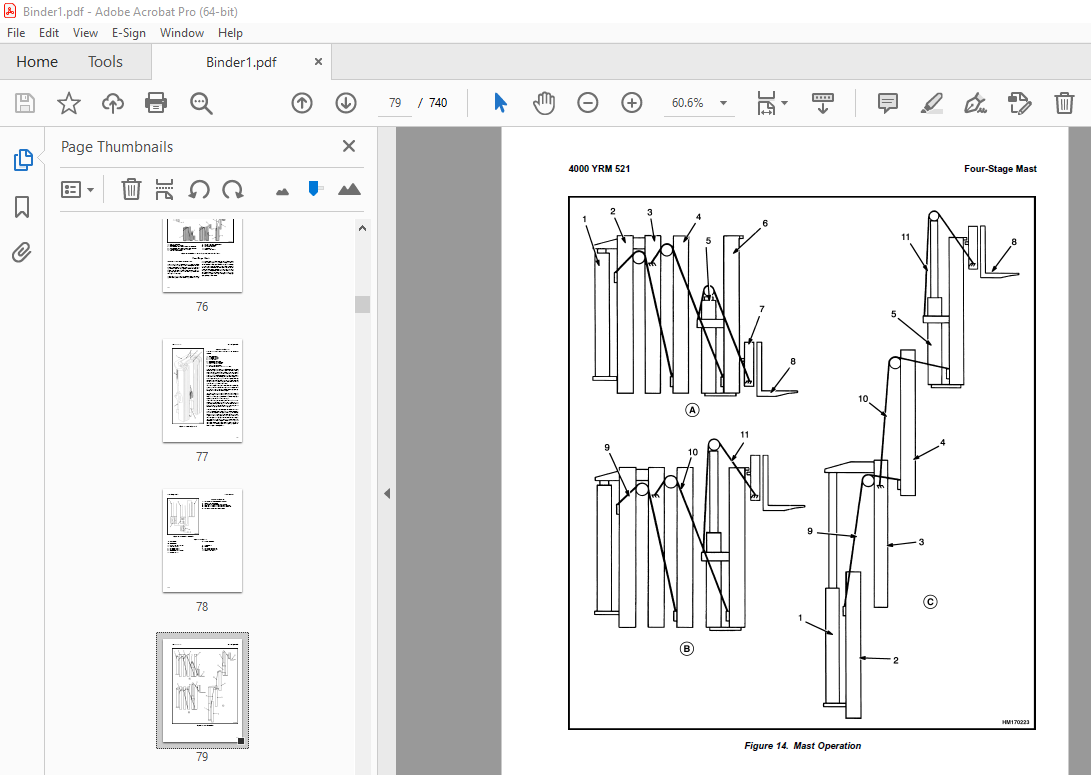

Four-Stage Mast 76

Description and Operation 76

Cylinder Cushion During Lifting Sequence 80

Cylinder Cushion During Lowering Sequence 81

524158891-4000YRM0522-(07-2010)-UK-EN 85

toc 85

Mast 85

Safety Precautions Maintenance and Repair 86

General 89

Safety Procedures When Working Near Mast 90

Fork Repair 92

Remove 92

Install 92

Carriages Repair 94

Standard Carriage, Remove 94

Hang-On Sideshift Carriage, Remove 95

Standard Carriage and Hang-On Sideshift Carriage, Repair 96

Standard Carriage, Install 97

Hang-On Sideshift Carriage, Install 98

Integral Sideshift Carriage 98

Remove 98

Clean and Inspect 102

Repair 103

Install 104

Mast Repair 105

Remove 105

Two-Stage LFL and Two-Stage FFL Masts, Disassemble 107

Three-Stage FFL Mast 115

Disassemble 115

Mast and Chains, Clean and Inspect 118

Two-Stage LFL and Two-Stage FFL Mast, Assemble 119

Three-Stage FFL Mast, Assemble 120

Install 121

Lift Cylinders Repair 123

Main Lift Cylinders, Remove 123

Free-Lift Cylinder, Remove 123

Cylinders, Disassemble 124

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 124

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 126

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 126

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 127

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 128

Clean and Inspect 129

Cylinders, Assemble 129

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 129

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 130

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 131

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 131

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 132

Main Lift Cylinders, Install 133

Free-Lift Cylinder, Install 133

Header Hose Arrangements 134

Two-Stage LFL Mast, New Hose Install 134

Two-Stage LFL Mast, Adjust Hoses After Installation 139

Two-Stage FFL Mast, New Hose Install 139

Two-Stage FFL Mast, Adjust Hoses After Installation 147

Three-Stage FFL Mast, New Hose Install 147

Three-Stage FFL Mast, Adjust Hoses After Installation 158

Header Hose Arrangement 159

Two-Stage LFL Mast, New Hose Install 159

Two-Stage LFL Mast, Adjust Hoses After Installation 164

Two-Stage FFL Mast, New Hose Install 164

Two-Stage FFL Mast, Adjust Hoses After Installation 170

Three-Stage FFL Mast, New Hose Install 170

Three-Stage FFL Mast, Adjust Hoses After Install 179

Lift and Tilt System Leak Check 180

Lift Cylinders Leak Check 180

Tilt Cylinders Leak Check 180

Tilt Cylinders Adjustment 181

Lift Chains Adjustment 183

Mast Adjustment 185

Carriage Adjustment 187

Troubleshooting 188

tables 85

Table 1 Hook-Type Carriage Chain Adjustment 183

Table 2 Pin-Type Carriage Chain Adjustment 184

524164212-0100YRM0588-(04-2002)-UK-EN 191

toc 191

Frame 191

Safety Precautions Maintenance and Repair 192

General 195

Description 195

Overhead Guard Repair 196

Remove 196

Install 197

Hood and Seat Assembly Repair 197

Remove 199

Install 199

Counterweight Repair 199

Remove 199

Install 200

Auxiliary Counterweight Repair 201

Remove 201

Install 201

Hydraulic Tank Repair 202

Inspect 202

Small Leaks, Repair 202

Large Leaks, Repair 202

Clean 202

Steam Method 202

Chemical Solution Method 202

Additional Preparations for Repair 203

Safety Labels 203

Battery Size Specifications 205

tables 191

Table 1 Battery Platform Weights 200

Table 2 Battery Size Specifications – Type: Lead-Acid Battery 205

524164213-1300YRM0568-(04-2002)-UK-EN 209

toc 209

Transaxle 209

Safety Precautions Maintenance and Repair 210

General 213

Lubrication 214

Transaxle Repair 214

Remove 214

Inspect 215

Install 215

S2 Series Transaxle 216

Disassemble 216

Inspection 218

Assemble 218

General 218

Ring Gear, Install 218

Intermediate Shaft, Install 219

Axle Shaft, Install 219

Pinion Gear, Install 220

Final Assembly 223

S1 Series Transaxle 224

Disassemble 224

Assemble 226

Troubleshooting 227

tables 209

Table 1 Transaxle Identification 213

Table 2 Transaxle Specifications 213

Table 3 Gear Teeth Contact Pattern 222

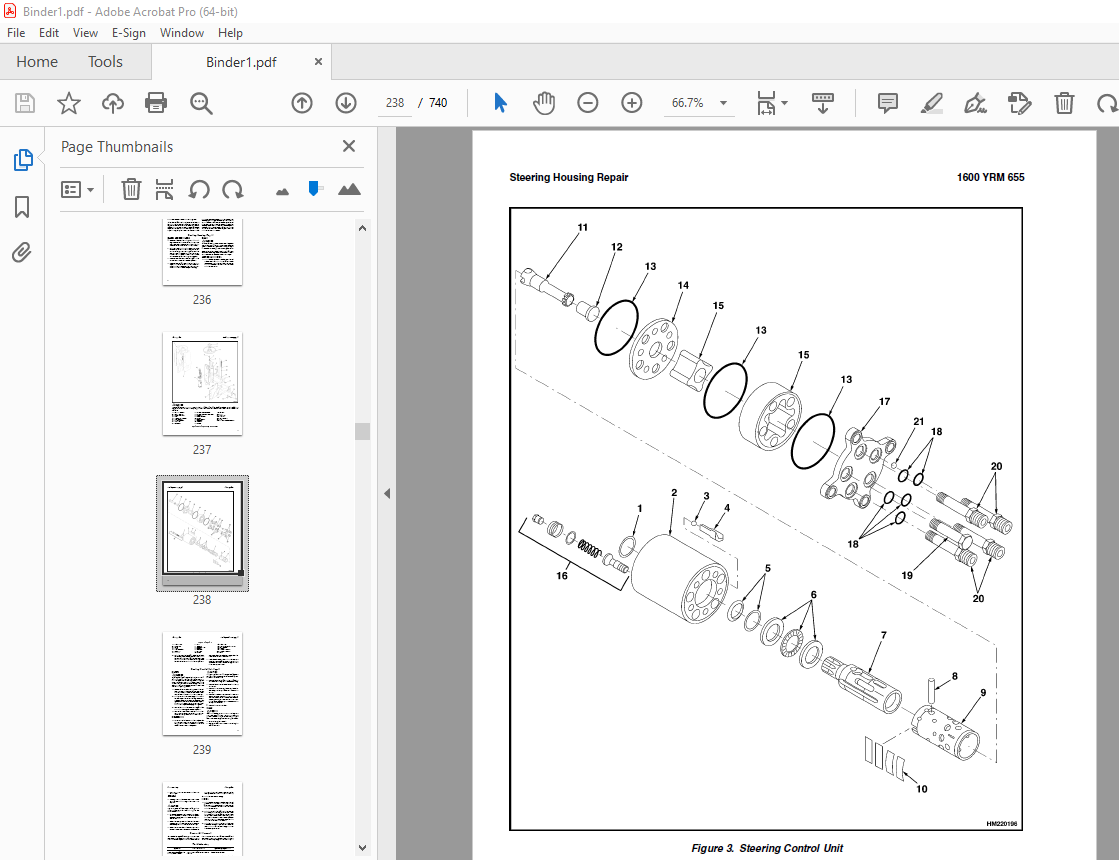

524164214-1600YRM0655-(04-2002)-UK-EN 231

toc 231

Steering Housing and Steering Control Unit 231

Safety Precautions Maintenance and Repair 232

General 235

Description 235

Operation 236

Steering Housing Repair 236

Remove and Disassemble 236

Clean 236

Assemble and Install 236

Steering Control Unit Repair 239

Remove 239

Disassemble 239

Clean 239

Assemble 240

Install 240

System Air Removal 240

Troubleshooting 240

524164215-1600YRM0687-(04-2002)-UK-EN 245

toc 245

Steering System 245

Safety Precautions Maintenance and Repair 246

General 249

Operation 249

Steering Wheel and Column Assembly 250

Description 250

Remove 250

Install 253

Power Steering Pump and Motor 254

Description 254

Remove 254

Install 256

Disassemble 256

Assemble 257

Steering Axle Components 258

General 258

Wheel and Tire Assembly 258

Remove 258

Install 259

Wheel Hub Assembly 259

Remove 259

Install 259

Steering Axle Assembly 259

Remove 259

Clean 260

Install 262

Steering System Air Removal 262

Operation Check 263

Steering Pressure Check 263

Troubleshooting 263

524164216-1800YRM0570-(04-2002)-UK-EN 269

toc 269

Brake System 269

Safety Precautions Maintenance and Repair 270

General 273

Description 273

Service Brake Pads Repair 273

Remove 273

Install 273

Service Brake Caliper Repair 274

Remove 274

Install 275

Disassemble 275

Assemble 276

Park Brake Caliper Repair 276

Remove 276

Install 276

Disassemble 277

Assemble 277

Master Cylinder Repair 278

Remove 278

Install 278

Disassemble 278

Assemble 279

Foot-Operated Park Brake Lever Assembly Repair 279

Remove 279

Install 281

Electrically Released Park Brake Repair 282

Mechanical Operation 282

Remove 282

Install 285

Electrically Released Park Brake – Electrical Components Repair 286

Control Box 286

Remove 286

Install 286

Terminal Block 286

Remove 286

Install 288

Park Brake Adjustment 288

Service Brake Adjustment 289

Brake System Air Removal 289

Troubleshooting 290

524164217-2000YRM0576-(04-2002)-UK-EN 295

toc 295

Main Control Valve 295

Safety Precautions Maintenance and Repair 296

General 299

Description 299

Operation 300

Lift Section 301

Tilt Section 301

Tilt Backward 301

Tilt Forward 301

Relief Valve 301

Main Control Valve Repair 301

Remove 301

Install 304

Disassemble 305

Clean and Inspect 307

Assemble 307

Relief Valve Check 308

Vane Settings Adjustment 308

Mast Tilt Adjustment 309

Troubleshooting 310

524164218-2200YRM0697-(08-2005)-UK-EN 315

toc 315

SX/SR Transistor Motor Controller and Handset 315

Safety Precautions Maintenance and Repair 316

Introduction to SEM 319

Advantages of Transistorized SEM 319

Features of SEM 320

Solid-State Reversing 320

Performance and Efficiency 320

Field Weakening 320

Regenerative Braking 320

SX Transistor Motor Controllers 321

Introduction 321

Proportional Operation for Dual-Motor Trucks 321

General 321

Operation 323

Controller Features 325

General 325

Creep Speed 325

Controlled Acceleration 325

Current Limit 325

Braking 325

Regenerative Braking to Zero Speed 325

Pedal Position Braking 326

Auto Braking 326

Conventional Plug Braking 326

Auxiliary Speed Control 326

Field Weakening 326

Speed Limits 326

Ramp Operation 326

Ramp Start 326

Antirollback 327

Steer Pump Contactor Time Delay 327

On-Board Coil Drivers and Internal Coil Suppression 327

System Protective Override 327

SRO (Static Return to Off) 327

Accelerator Volts Hold Off 327

Pulse Monitor Trip (PMT) 327

Thermal Protector (TP) 327

Low Voltage 327

SR Lift Pump Controllers 328

Sensor Interface/Contactor Driver Module 332

Diagnostic Status Codes and Troubleshooting 332

General Maintenance Instructions 332

Special Precautions 332

Diagnostics 333

Systems Diagnostics 333

Status Codes 333

Standard Status Codes 333

Stored Status Codes 333

Other Features 334

Hourmeter Readings 334

Maintenance Alert and Speed Limit 334

Battery Discharge Indication (BDI) 334

Internal Resistance Compensation 334

Handset Programmable 334

RS 232 Communication Ports 334

Circuit Board Coil Driver Modules 334

Maintenance Management Capability 334

Interactive Instrument Panel Modes 335

General Troubleshooting Instructions 337

Status Code Troubleshooting Tables 338

SX/SR Handset Instructions 374

General Features 374

Connecting the Handset 376

Startup Sequence 376

Setup Mode 377

Stored Status Code Mode 378

Clearing the Stored Status Codes 378

Restarting Lift Truck 378

SX Traction Controller Function Descriptions 379

Premium Instrument Panel Interactive Modes 386

SR Pump Controller Function Descriptions 388

Premium Instrument Panel Interactive Modes 391

tables 315

Table 1 SX Traction Controller Connections/Descriptions 322

Table 2 SR Lift Pump Controller Connections/Descriptions/Status 329

Table 3 Instrument Panel Function Number Correlation 335

Table 4 Traction Function Settings Logic 336

Table 5 Lift Pump Function Settings Logic 336

Table 6 Speed/Torque Compensation 390

Table 7 Traction Controller Settings – Standard With Auto Regen 393

Table 8 Traction Controller Settings – Standard Without Auto Re 394

Table 9 Traction Controller Settings – High Performance With Au 396

Table 10 Lift Pump Controller Settings 397

524164219-2200YRM0698-(04-2002)-UK-EN 401

toc 401

Electrical System 401

Safety Precautions Maintenance and Repair 402

General 405

Electrical Compartment 406

Instrument Panels 412

Standard Display (Current Configuration) 412

Premium Display (Current Configuration) 413

Replacement (Current Configuration) 414

Control and Power Fuses 415

Steer Angle Potentiometer 415

General 415

Operation 415

Example 416

Installation 417

Positioning Steer Tire for Straight Travel 417

Adjustment 417

Handset Method 418

Voltmeter Method 418

Testing 420

Power Steering Control Assembly 420

General 420

Operation 420

Testing 421

Removal and Replacement 423

Power Steering Control Assembly 423

Optical Encoder 423

Lift Pump Control Board 424

General 424

Testing 424

Bypassing Lift Pump Control Board 428

Sensor Interface/Contactor Driver Module 428

General 428

Troubleshooting 430

Other Control Components 431

Key Switch 432

Seat Switch 432

Replace 433

Parking Brake Switch 433

Check 433

Replace 434

Accelerator Switch Assembly 434

Check 435

Replace 435

Direction Switches ( Foot Directional Control Pedal) 435

Check 435

Replace 435

Direction Switches (Steering Column) 436

Check 436

Replace 436

Brake Fluid Switch 436

Hydraulic Cutoff Switch 436

Check 437

Replace 437

Stop Light Switch 437

Check 437

Replace 438

Motor Temperature Switches 438

Rocker Switches for Lights 438

DC-to-DC Converter 439

Backup Light Relay Panel 439

Backup Light Switch Relay 440

Horn and Horn Button 440

Horn 440

Horn Switch and Cover (Button) 441

Lights and Reverse Alarm 441

Light Assemblies Replacement 443

Tail Light 443

Flashing Light Assembly 443

Front Driving Light and Rear Work Light Assemblies 444

Spot Light Assembly 447

tables 401

Table 1 Potentiometer Specifications 420

Table 2 Power Steering Control Assembly Specifications 421

Table 3 Lift Pump Control Board Test Point/Function Relationshi 425

Table 4 Lift Pump Control Board Troubleshooting Guide 426

Table 5 Lift Pump Control Board Test Values 427

Table 6 Lift Pump Control Board Bypass Test 428

Table 7 SICDM Connections/Descriptions/Status Codes 429

524164220-2200YRM0779-(06-2005)-UK-EN 451

toc 451

SR/SP Transistor Motor Controller and Handset 451

Safety Precautions Maintenance and Repair 452

Introduction to SEM 455

Advantages of Transistorized SEM 455

Features of SEM 455

Solid-State Reversing 455

Performance and Efficiency 455

Field Weakening 455

Regenerative Braking 455

SR Transistor Traction Motor Controllers 456

Introduction 456

Proportional Operation for Dual-Motor Trucks 456

General 456

Operation 459

Controller Features 459

General 459

Creep Speed 459

Controlled Acceleration 460

Current Limit 460

Braking 460

Regenerative Braking to Zero Speed 460

Pedal Position Braking 460

Auto Regenerative Braking 460

Conventional Plug Braking 460

Auxiliary Speed Control 461

Field Weakening 461

Speed Limits 461

Ramp Operation 461

Ramp Start 461

Antirollback 461

Steer Pump Contactor Time Delay 461

On-Board Coil Drivers and Internal Coil Suppression 461

System Protective Override 461

SRO (Static Return to Off) 461

Accelerator Volts Hold Off 461

Pulse Monitor Trip (PMT) 462

Thermal Protector (TP) 462

Low Voltage 462

SP Lift Pump Controllers 462

Sensor Interface/Contactor Driver Module 466

Diagnostic Status Codes and Troubleshooting 466

General Maintenance Instructions 466

Special Precautions 466

Diagnostics 467

Systems Diagnostics 467

Status Codes 467

Standard Status Codes 467

Stored Status Codes 468

Other Features 468

Hourmeter Readings 468

Maintenance Alert and Speed Limit 468

Battery Discharge Indication (BDI) 468

Internal Resistance Compensation 468

Handset Programmable 468

RS 232 Communication Ports 468

Circuit Board Coil Driver Modules 468

Maintenance Management Capability 469

Interactive Instrument Panel Modes (Premium Only) 469

General Troubleshooting Instructions 471

Status Code Troubleshooting Tables 472

Description 472

SR/SP Handset Instructions 510

General Features 510

Connecting Handset 512

Startup Sequence 513

Setup Mode 514

Stored Status Code Mode 514

Clearing Stored Status Codes 515

Restarting Lift Truck 515

SR Traction Controller Function Descriptions 516

Premium Instrument Panel Interactive Modes 522

SP Pump Controller Function Descriptions 525

Premium Instrument Panel Interactive Modes 528

tables 451

Table 1 SR Traction Controller Connections/Descriptions 458

Table 2 SP Lift Pump Controller Connections/Descriptions/Status 463

Table 3 Instrument Panel Function Number Correlation 469

Table 4 Traction Function Settings Logic 470

Table 5 Lift Pump Function Settings Logic 471

Table 6 Speed/Torque Compensation 527

524164221-8000YRM0586-(04-2002)-UK-EN 533

toc 533

Capacities and Specifications 533

Safety Precautions Maintenance and Repair 534

Wheels and Tires 537

Motors (Dual Voltage 36/48) 537

Mast Tilt Performance 537

Mast Speeds 538

19cc Pump One- and Two-Speed Contactor 538

19cc Pump Transistor Control 539

12cc Pump One- and Two-Speed Contactor 540

12cc Pump Transistor Control 541

Mast/Tilt Drift Speeds 541

Hydraulic System 542

Torque Specifications 542

Frame 542

Transaxle 542

Brake System 542

Wheels 542

Steering System 543

Hydraulic System 543

Mast/Tilt/Attachment Systems 543

Accelerator Potentiometer Checks 543

Adjustments 544

EV 100 LX Traction Card 544

EV 100 LX Pump Card 544

Controller Settings 545

SR/SP Traction Controller Settings – Standard With Auto Regen 545

SR/SP Traction Controller Settings – Standard Without Auto Decel 547

SR/SP Lift Pump Controller Settings 548

SR/SP Traction Controller Settings – 36V Energy Option 549

Battery Size Specifications 550

Type: Lead Acid Battery 550

524164222-8000YRM0696-(04-2002)-UK-EN 555

toc 555

Diagrams 555

Safety Precautions Maintenance and Repair 556

524164223-8000YRM0699-(10-2007)-UK-EN 601

toc 601

Periodic Maintenance 601

Safety Precautions Maintenance and Repair 602

General 605

How to Move Disabled Lift Truck 605

How to Tow Lift Truck 605

How to Put Lift Truck on Blocks 606

How to Raise Drive Tires 606

How to Raise Steer Tires 607

Maintenance Schedule 607

Maintenance Procedures Every 8 Hours or Daily 610

Before Operation Checks 610

Hydraulic System 610

Battery 611

Battery Restraint System 611

Tires and Wheels 612

Safety Procedures When Working Near Mast 613

Forks 615

Adjust 615

Remove 615

Inspect 616

Install 617

Mast and Lift Chains 617

Lift Chain, Adjustment 617

Operation Check 618

Gauges and Horn 618

Control Levers and Pedals 618

Service Brakes 618

Parking Brake 619

Steering System 619

Maintenance Procedures Every 500 Hours or 3 Months 619

Hydraulic Tank Breather 619

Wheel Nut Torque 619

Steering Actuator Mounting Bolts 619

Transaxle 620

Lift System Operation 620

Mast 621

Lift Chains 622

Forks 623

Safety Labels 623

Brake Fluid 623

Other Lubrication 624

Electrical Inspection 624

Special Precautions 624

Contactors 625

Motor Brushes 625

Parking Brake 625

Maintenance Procedures Every 2000 Hours or Yearly 632

Hydraulic System 632

Hydraulic Oil Filter, Change 632

Hydraulic Oil Strainer, Check 632

Hydraulic Oil, Change 632

Brakes 632

Parking Brake, Adjust 633

Transaxle 633

Maintenance Procedures Every 4000 Hours 635

Transaxle 635

Lift and Tilt System Leak Check 635

Lift System 635

Tilt System 636

Battery Maintenance 636

How to Charge Battery 636

How to Change Battery 637

Battery Size Specifications 638

Wheels and Tires Maintenance 639

General 639

How to Change Tires 640

Steer and Drive Wheels 640

Pneumatic Tires 641

Remove Wheel From Lift Truck 641

Tire Sizes and Pressures 641

Remove Tire From Wheel 642

Install Tire on Wheel 643

Add Air to Tires 644

Pneumatic-Shaped Solid Tires 645

Remove Wheel From Lift Truck 645

Press Tire From Wheel 645

Install Tire on Wheel 647

Install Wheel and Tire 648

tables 601

Table 1 Maintenance Schedule 608

Table 2 Transaxle Specifications 634

Table 3 Battery Size Specifications – Type: Lead-Acid Battery 638

524166844-2200YRM0942-(08-2007)-UK-EN 651

toc 651

Display Panel for SEM Controls 651

Safety Precautions Maintenance and Repair 652

General 655

SEM Display Panel Features 655

Descriptions of Common Features 655

LED Symbol Indicators 655

LCD Screen 655

Battery Discharge Indicator (BDI) 656

Service Reminder 656

Status Codes 656

Hourmeter 656

Additional Features of Premium Display Panel 656

Descriptions of Additional Features (Available With Premium Disp 656

LCD Screen 656

Operator Passwords 657

Daily Check List and Service Items 657

Performance Modes 657

Status Code Lists 657

Adjustment of BDI 657

SEM Display Panel Indicators 658

All Indicator Symbols 658

Hourmeter Indicator Symbol 658

Wrench Indicator Symbol 658

Battery Indicator Symbol 658

Battery State-of-Charge (BDI) 658

Brake Fluid Too Low Symbol 659

Parking Brake Symbol 659

Fasten Seat Belt Symbol 659

LCD Screen (Standard Display Panel) 660

Additional Components of Premium Display Panel 660

Alphanumeric Screen 660

STAR Push Button 660

Push Buttons 1 Through 5 660

Adjustments With a Computer 660

Computer System 660

Connect PC to SEM Display Panel 661

ITW Switches Windows Software Program (for SEM Display Panel) 662

Description 662

Getting Help 662

Hardware and Software Requirements 662

Install 662

How to Start ITW Switches Program 662

Menus 666

Sample Sessions 675

Replacement 697

SEM Display Panel 697

Remove and Replace 697

tables 651

Table 1 Adapter Pins (DB25F to DB9) 661

524167640-2200YRM0947-(08-2007)-UK-EN 703

toc 703

Troubleshooting and Adjustments With a Computer 703

Safety Precautions Maintenance and Repair 704

Computer System 707

Connect a PC to a Control Card 708

Installation 709

SMARTSET™ Windows Software Program 709

How to Start the Program 709

DEMO Mode 710

Selecting the Communications Port 712

Verification of Controller and Lift Truck 713

Select Lift Truck Series 715

Controller Card Register Parameter List 716

How to Change a Parameter 717

How to Save a Changed Parameter File 718

How to Load a Saved Parameter File 720

How to Show and Remove Saved Parameter Files 720

How to Return to Factory Default Settings 721

How to Save Changes to Control Card 722

How to View Status Codes 723

Saving Status Codes 724

How to Show and Remove Saved Status Code Files 725

Closing and Clearing Status Code List 726

How to View Saved Register Data and Saved Status Data 727

How to Save Register Data and Status Code Data In RTF and TXT 729

GE Sentry™ Software Program 730

Installation 730

Description 730

How to Start GE SENTRY Program 730

How to Reset MIN and MAX Display 735

Graphing Mode 736

How to Exit GE SENTRY Program 737

tables 703

Table 1 Cable Connections – Computer to Control 707

Table 2 Adapter Pins (DB25F to DB9) 708

Table 3 Plug-Z Connection 709