$42.95

Yale Forklift D877 (GDPGLP300EB, GDPGLP330EB, GDGLPP360EB) Service Manual PDF

Yale Forklift D877 (GDPGLP300EB, GDPGLP330EB, GDGLPP360EB) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift D877 (GDPGLP300EB, GDPGLP330EB, GDGLPP360EB) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1298

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift D877 (GDPGLP300EB, GDPGLP330EB, GDGLPP360EB) Service Manual – PDF DOWNLOAD

524150779 1400YRM0046 (08 2012) US EN 1

toc 1

Differential 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Differential Repair 5

Remove 5

Differential Carrier From Axle Housing, Remove 5

Differential and Ring Gear From Differential Carrier, Remove 9

Drive Pinion and Pinion Carrier From Differential Carrier, Remov 11

Disassemble 12

Differential and Ring Gear Assembly, Disassemble 12

Drive Pinion and Pinion Carrier, Disassemble 13

Clean and Inspect 16

Assemble 17

Pinion, Bearings, and Pinion Carrier, Assemble 17

Pinion Bearings, Adjust Preload 17

Press Method 17

Yoke or Flange Method 18

Triple-Lip Seal, Install 19

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion) 20

Differential and Ring Gear, Assemble 22

Differential Gears Rotating Torque, Check 24

Differential and Ring Gear Assembly, Install 25

Differential Bearings, Preload Adjust 26

Ring Gear, Runout Check 27

Ring Gear Backlash, Adjust 28

Gear Set, Tooth Contact Pattern Check 30

Thrust Screw, Install and Adjust 33

Install 33

Differential Assembly Into Axle Housing, Install 33

Specifications 34

Troubleshooting 38

tables 1

Table 1 Ring Gear Backlash Adjustment Specifications 29

Table 2 Ring and Pinion Tooth Contact Adjustment 30

Table 3 General Specifications 34

Table 4 Rivet Installation Pressure 34

Table 5 Pinion Adjustment 34

Table 6 Pinion Preload Pressure 35

Table 7 Torque Specifications 36

Table 8 Torque Specifications for Metric Hardware 37

Table 9 Torque Specifications for Metric (Fine) Hardware 37

524150780 1400YRM0944 (08 2012) US EN 41

toc 41

Planetary Drive Axle 41

Safety Precautions Maintenance and Repair 42

General 45

Description 45

Operation 47

Identification 47

Removal 48

Disassembly 48

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 49

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 50

Wheel End 52

Spindle and Piston Housing 53

Cleaning 54

Clean Ground or Polished Parts 54

Clean Parts With Rough Finish 54

Clean Axle Assemblies 54

Drying Cleaned Parts 54

Corrosion Prevention 54

Parts Inspection 55

Tapered Roller Bearings 55

Bevel Pinion and Ring Gear Sets 56

Main Differential Assembly 56

Axle Shafts 56

Yoke 56

Brakes 56

Repair or Replace Parts 56

Repair Welding 57

Apply Silicone Gasket Material 57

Assembly 57

Spindle and Piston Housing to Axle Housing 57

Wet Disc Brakes 58

Adjust Wheel Bearing Preload 59

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 60

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 60

Planetary Spider Assembly 61

Installation 62

Fill Wet Disc Brakes With Hydraulic Fluid 62

Torque Specifications 63

Lubrication Specification 64

524150781 1400YRM0945 (08 2011) US EN 67

toc 67

Planetary Drive Axle 67

Safety Precautions Maintenance and Repair 68

General 71

Description 71

Operation 73

Identification 73

Removal 74

Disassembly 75

Brake Drum 75

Planetary Spider and Gearing Assembly GDP/GLP80-120DB (GDP/GLP17 76

Dry Brakes 76

Planetary Spider and Gearing Assembly GDP/GLP130-160EB (GDP/GLP3 78

Spindle and Brake Spider 80

Cleaning 80

Ground or Polished Parts 80

Parts With Rough Finish 81

Axle Assemblies 81

Drying Cleaned Parts 81

Corrosion Prevention 81

Parts Inspection 81

Tapered Roller Bearings 81

Bevel Pinion and Ring Gear Sets 82

Main Differential Assembly 83

Axle Shafts 83

Yoke 83

Brakes 83

Repair or Replace Parts 83

Repair Welding 83

Apply Silicone Gasket Material 83

Assembly 84

Spindle, Brake Spider, and Brake 84

Wheel End 85

Adjust Wheel Bearing Preload 85

Planetary Spider and Gearing Assembly GDP/GLP80-120DB (GDP/GLP17 86

Planetary Spider and Gearing Assembly GDP/GLP130-160EB (GDP/GLP3 87

Planetary Spider Assembly 87

Installation 88

Torque Specifications 89

Lubrication Specification 90

524150782 1600YRM0936 (03 2007) US EN 93

toc 93

Steering System 93

Safety Precautions Maintenance and Repair 94

General 97

Description 97

Steering Wheel and Column Assembly 99

General 99

Steering Wheel and Horn 99

Remove 99

Install 99

Steering Control Unit Repair 101

General 101

Description 101

Operation 101

Remove 102

Disassemble 102

Clean 105

Assemble and Install 105

Steering System Air Removal 111

Steering Relief Pressure Check 112

Troubleshooting 112

524150783 1600YRM0326 (03 2007) US EN 117

toc 117

Steering Axle 117

Safety Precautions Maintenance and Repair 118

General 121

Description 121

Steering Axle Assembly Repair 126

Steering Axle GP/GLP/GDP070-110LG/MG (B813), GC/GLC070-120LG/MG 126

Remove 126

Install 126

Steering Axle GDP60-70CA (GP/GLP/GDP135-155CA) (A878, B878), GLP 127

Remove 127

Install 127

Wheels and Hubs Repair (All Units) 128

Remove and Disassemble 128

Clean 128

Inspect 128

Assemble and Install 128

Spindles and Bearings Repair (All Units) 130

Remove 130

Clean 130

Assemble and Install 131

Tie Rods Repair (All Units) 132

Remove 132

Clean 132

Install 132

Steering Cylinder Repair 135

Remove and Disassemble 135

Clean and Inspect 135

Assemble and Install 135

Troubleshooting 136

524150784 1800YRM0937 (04 2010) US EN 141

toc 141

Dry Brake System 141

Safety Precautions Maintenance and Repair 142

General 145

Description 145

Operation 146

Service Brakes 146

Parking Brake 147

Air Tank Repair 148

Relief Valve 148

Drain Valve 149

Brake Pedal Valve Repair 149

Remove 149

Disassemble, Inspect, and Assemble 150

Install 150

Air Chambers Repair 151

Remove 151

Disassemble 151

Inspect 151

Assemble 153

Install 153

Actuator Arms Repair 153

Remove 153

Inspect 154

Install 154

Brake Assemblies Repair 155

Brake Shoe, Remove 155

Camshaft, Remove 157

Clean 157

Inspect 158

Camshaft, Install 158

Brake Shoe, Install 159

Air Dryer 159

Description 159

Cartridge 159

Remove 159

Install 159

Filter 161

Remove 161

Install 161

Quick-Release Valve 161

Governor Check and Adjustment for Air Compressor 162

Brake Shoes Adjustment 162

Specifications 164

Troubleshooting 165

Service Brakes 165

Service Brakes, Park Function 167

tables 141

Table 1 Air Chambers Operation 147

524150785 1800YRM0951 (02 2018) US EN 171

General 175

Description and Operation 175

Service Brakes 175

Parking Brake 175

Oil Cooler Circuit 175

Pressure Switch Replacement 178

Accumulators Replacement 179

Brake Treadle Valve Repair 179

Remove and Disassemble 179

Clean and Inspect 180

Assemble and Install 180

Parking Brake Valve Repair 180

Remove 180

Clean and Inspect 180

Repair 180

Install 180

Parking Brake Caliper Repair 180

Remove 180

Disassemble 183

Inspect 183

Install 183

Adjust 183

Brake Pad Repair 184

Inspect 184

Remove 184

Install 184

Seals Repair 184

Remove 184

Install 184

Service Brake Repair 185

Remove and Disassemble 185

Drain Lubricating Oil 185

Drain Coolant Oil 191

Disconnect Brake Lines 191

Wheel End With Outer Bearing on Ring Gear Hub Journal, Lift Truck Models GDP/GLP130-160EB (GP/GDP/GLP300-360EB) 191

Wheel End With Outer Bearing on Spindle Journal, Lift Truck Models GDP/GLP80-120DB (GP/GDP/GLP170-280DB) 192

Brake Disc Housing Assembly Wheel End 193

Brake Piston Housing 194

Brake Piston Housing and Wheel Spindle 195

Inspect 195

Clean 197

Assemble 198

Wheel Spindle 198

Brake Piston Housing 199

Piston Assembly 200

Brake Disc Housing 201

Duo-Cone Face Seal Into Brake Disc Housing and Into Hub 202

Check for Correct Installation of Duo-Cone Seal 204

Wheel Hub to Brake Disc Housing 204

Adjust 205

Fill Brake System With Coolant Oil 206

System Air Removal 206

Adjust Brake With New Disc Pack 206

Coolant Change Intervals 207

Coolant Draining and Filling 207

Wet Brake Noise Reduction 208

General 208

Adding Additive To Transmission 209

Specifications 210

Minimum Brake Disc Thickness 213

Hydraulic Fluid for Brake Actuation 213

Brake Coolant Specifications 213

Coolant Change Intervals 213

Hydraulic Fluid Specifications 213

Troubleshooting 214

524150787 1900YRM0938 (03 2007) US EN 219

toc 219

Hydraulic System 219

Safety Precautions Maintenance and Repair 220

General 223

Description and Operation 223

Hydraulic Tank 223

Hydraulic Pump 224

Steering Priority Flow Valve 224

Pilot Valve 225

Main Control Valve 227

Unloader Valve 228

Hydraulic Operation 229

Checks And Adjustments 232

Quick Disconnect Fittings 232

Steering Priority Flow Valve 232

Steering Relief Pressure 232

Modulator Valve 233

Pilot Valve and Pressure Reducing Valve 233

Accumulator 234

Filter 234

Main Control Valve 234

Relief Pressure Check 234

Check Valves 235

Unloader Valve 235

Hydraulic Pump Repair 236

Remove 236

Disassemble 236

Clean and Inspect 236

Assemble 237

Install 238

Pilot Accumulator Replacement 238

Remove 238

Install 238

Pilot Valve Repair 238

Remove 238

Disassemble 239

Clean and Inspect 239

Assemble 239

Install 240

Control Levers and Joystick Repair 241

Remove 241

Install 241

Calibration and Diagnostics 242

General 242

Description 242

Lever and Joystick Calibration 242

Flow Adjustment 242

Dead Band Value Setting 243

Lowering Delay 244

PWM and I/O Module Readouts 244

Function Disable 245

General Startup 245

Minimum system requirements 245

Install the Hydraulic Controls Program 245

DelayTimeFile (Reset) 245

Select the Processor Speed 246

Hydraulic Controls Program 246

Calibration 247

Joystick/Lever Calibration 247

Levers 247

Joystick 248

Valve Flow Adjustment 248

Diagnostics 249

Calibration System Shutdown 249

LED Diagnostics 250

Electrical Connections 252

Specifications 256

tables 219

Table 1 Main Control Valve Port Settings 225

Table 2 Processor Speed Settings 245

Table 3 PWM Board LED Error Codes 250

Table 4 Altering PT I/O Board LED’s (Old Logic) 251

Table 5 Altering PT I/O Board LED’s (New Logic) 251

Table 6 Fixed PT Logic I/O Boards LED’s 252

Table 7 PWM Driver Module 253

Table 8 Input/Output Module 1 253

Table 9 Input/Output Module 2 254

Table 10 Altering PT 255

Table 11 Fixed PT 255

524150788 2000YRM0943 (03 2007) US EN 259

toc 259

Main Control Valve 259

Safety Precautions Maintenance and Repair 260

General 263

Description 263

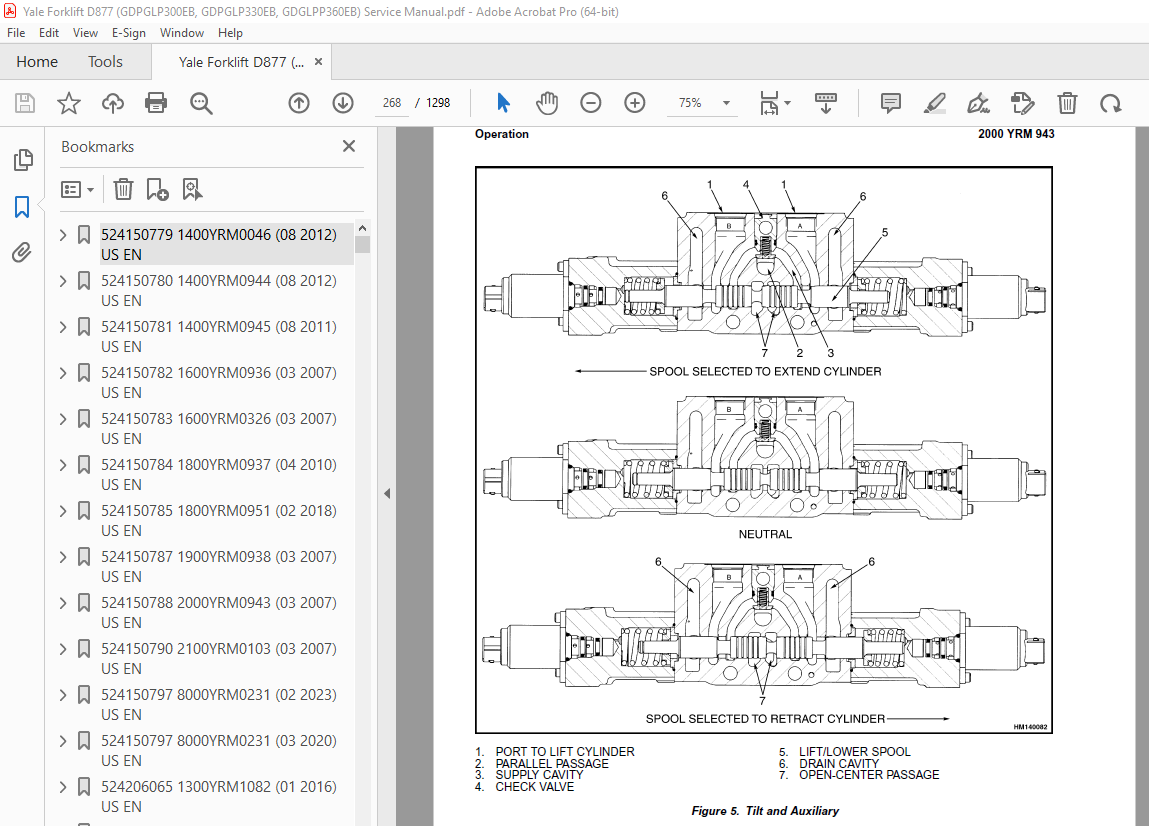

Operation 266

Lift Section 266

Tilt/Auxiliary Section 266

Relief Valves 266

Unloader Valve 266

Main Control Valve Repair 269

Remove 269

Disassemble 269

Auxiliary Side 269

Lift Side 269

Clean and Inspect 272

Assemble 272

Auxiliary Side 272

Lift Side 272

Install 272

Pressure Relief Valve Check and Adjustment 273

Check and Adjust 273

Replace 273

Specifications 274

Troubleshooting 274

524150790 2100YRM0103 (03 2007) US EN 279

toc 279

Tilt Cylinders 279

Safety Precautions Maintenance and Repair 280

General 283

Description 283

Tilt Cylinder Repair 283

Remove 283

Disassemble 283

Clean 283

Assemble 284

Tilt Cylinders With O-Ring or Single-Lip Seals 284

Tilt Cylinders 285

Install 286

Tilt Cylinder Leak Check 288

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 289

Torque Specifications 289

Piston Rod Nut 289

Retainer 289

Troubleshooting 290

tables 279

Table 1 Movement Rates (Maximum) for Tilt Cylinders 288

524150797 8000YRM0231 (02 2023) US EN 295

General 301

Threaded Fasteners 301

Nomenclature, Threads 301

Strength Identification 302

Cotter (Split) Pins 303

Fastener Torque Tables 308

Conversion Table 310

524150797 8000YRM0231 (03 2020) US EN 317

General 321

Threaded Fasteners 321

Nomenclature, Threads 321

Strength Identification 322

Cotter (Split) Pins 323

Fastener Torque Tables 328

Conversion Table 330

524206065 1300YRM1082 (01 2016) US EN 337

Series Code / Model Designation Reference Table 341

Description of Operation 342

General 342

Torque Convertor, Pump Drive, and Pressure Regulating Valve 342

Input Shaft and Directional Clutches 343

Range Clutches 346

Output Section 346

Transmission Controls 346

Operation of the Valve 348

Selection of Range 354

Pressure Switch 354

Electric Solenoid Controls 354

Transmission Specifications 372

Transmission Identification 372

Weight, Dimensions, and Oil Capacity 372

Transmission Repair 373

Disassemble 373

Reverse and Second-Speed Clutch 403

Clean and Inspect 419

Housings 419

Oil Seals and Gaskets 420

Bearings 420

Gears and Shafts 420

Assemble 420

Reverse and Second-Speed Clutch 431

Control Valve Repair 471

Remove 471

Disassemble and Assemble 471

Clean and Inspect 474

Housings 474

Oil Seals and Gaskets 474

Install 474

Stall Test 476

Transmission Calibration and Electrical Troubleshooting 477

Userlink® 477

Connection 477

Clutch Filling Calibration 478

Purpose 478

Clutch Filling Calibration Procedure 478

Alternative Clutch Filling Calibration Procedure 478

Heat-up Mode 479

Heat-up Mode Stall Test 479

Inching Pedal Calibration 480

Purpose 480

Troubleshooting 480

Transmission Display Warning Codes 480

Access 481

Clear 481

Exit 481

Limp Home Mode 518

Shutdown Mode 518

Pressure Feedback Sensor 518

Transmission Oil Pressure Check 519

Pressure and Temperature Specifications 519

Electrical Specifications 525

Hydraulic Cooler Lines Specifications 525

Torque Specifications 526

Torque Specifications for Lubricated or Plated Screw Threads 526

Troubleshooting 528

524206632 2200YRM1105 (03 2007) US EN 535

toc 535

Instrument Panel Indicators and Senders 535

Safety Precautions Maintenance and Repair 536

General 539

Description 539

General 539

Instrument Panel Meters, Indicators, and LCD Display 539

Connector 544

Seat Switch Logic 545

Central Warning Light Output 545

Buzzer Output 545

Instrument Panel 546

Remove 547

Sender Replacement 548

Fuel Level Sender (Diesel Engine Only) 548

Engine Oil Pressure Sender 548

Brake Pressure Sender 548

Low Coolant Sender 549

Vacuum Switch 549

Specifications 550

Troubleshooting 551

tables 535

Table 1 Instrument Panel and Indicators 540

Table 2 Pin Description 544

Table 3 Sender Description 545

524211827 0600YRM1101 (11 2018) US EN 555

Series Code / Model Designation Reference Table 559

General 559

Fault Codes 560

Normal Mode 560

Fault Log Mode 561

Access 561

Exit 561

Clear 561

Electronic Throttle Calibration 561

Electronic Throttle Calibration Procedure 562

Stationary Regeneration Procedure 562

524230692 8000YRM1181 (01 2017) US EN 591

Series Code / Model Designation Reference Table 595

General 596

Weight and Dimensions 596

Loading Procedures 604

Loading A Truck on a Transport 604

Loading Disassembled Components 604

Unloading Procedures 605

Unloading Complete Truck or Basic Truck From Transport 605

Lifting 605

Driving On/Off a Trailer 606

Unloading Disassembled Components 606

Removal of Forks Attached to Basic Truck 606

Removal of Forks Attached to the Carriage 606

Truck Assembly 607

Safety procedures When Working Near the Mast 608

Mast Installation 609

Preparations 609

Adjusting the Tilt Cylinders 611

Connecting the Lift Cylinders 611

Connecting the Mast Supply Hoses 612

Carriage and Forks 613

Installing the Carriage 613

Connecting the Header Hoses to the Carriage 613

Install the Forks 613

Installing Pin-Type Forks 613

Installing Quick Disconnect DFSSFP Forks 615

616

Installing Integrated DFSSFP Forks 616

Adjusting the Carriage 616

Adjusting Header Hose Tension 617

Adjusting the Electrical Cable Tension 618

Installing the Cab Lights 618

Adding the Mast Labels 619

Lubrication Points 619

Pre-Delivery Inspection 620

Empty Seat Engine Shut Down 620

Pre-Delivery Inspection 620

Pneumatic Tires and Wheels 621

Remove Wheels From Lift Truck 621

Remove Tire From Wheel 622

Install Tire on the Wheel 624

Adding Air Pressure to the Tires 626

Solid Rubber Tires, Remove Tire From the Wheel 626

Solid Rubber Tires, Install Tire on the Wheel 628

Install Wheels on Lift Truck 630

Moving and Towing 631

Moving a Disabled Lift Truck 631

Precautions 631

Towing A Lift Truck 632

524298462 8000YRM1346 (05 2007) US EN 635

toc 635

Diagrams 635

Safety Precautions Maintenance and Repair 636

524298463 8000YRM1347 (09 2013) US EN 689

toc 689

Periodic Maintenance 689

Safety Precautions Maintenance and Repair 690

General 695

Serial Number Data 695

How to Move a Disabled Lift Truck 696

How to Tow the Lift Truck 696

How to Put a Lift Truck on Blocks 696

How to Raise the Drive Tires 697

How to Raise the Steer Tires 697

How to Clean a Lift Truck 698

Maintenance Schedule 698

Maintenance Procedures Every 8 Hours or Daily 707

How to Make Checks With the Engine Stopped 707

Warning and Safety Labels 707

Wheels, Tires, and Tire Pressure 707

Wheel Nuts 707

Inspection of Forks, Mast, Carriage, Attachment, and Lift Chains 708

Header Hose Assembly 708

Hydraulic Tank Breather 710

Forks, Adjust 710

Forks, Remove 710

Forks, Install 710

Air Precleaner Dust Bowl 710

Check for Fuel, Oil, or Coolant Leaks 711

Engine Air Intake Piping and Charge Air Piping 711

Drive Belts 711

Radiator Sections for Engine Coolant, Charge Air Cooler, Transmi 711

Engine Compartment 711

Hydraulic System Oil 711

Windshield Washer Fluid 712

Coolant Level 712

Engine Oil 712

How to Add Fuel to the Lift Truck 715

Diesel Fuel 715

Liquefied Petroleum Gas (LPG) 716

Remove 716

Fill 716

Install 717

How to Make Checks With the Engine Running 717

Operator Restraint System (Seat Belt and Seat Rails) 717

Steering Column Latch 717

Gauges, Lights, Horn, Fuses, and Relays 718

Windows and Mirrors 723

Engine and Transmission Fault Codes 723

Engine Air Filter 723

Diesel Fuel Filter/Water Separator 723

Cooling System 723

Fuel System 724

Control Levers, Switches, and Pedals 724

Steering System 724

Parking Brake 724

Service Brakes 724

Mast, Carriage, and Attachment 724

Signals from the Spreader Control System 725

Operator Presence System (OPS) 725

Transmission 725

Transmission Oil Level 725

First Inspection After First 100 Hours of Operation 726

Lift Chains 726

Hydraulic System Oil Filter 726

Transmission Oil Filter 726

Hydraulic Pilot Valve Oil Screen 726

Wet Brake System Filter 726

Maintenance Procedures Every 250 Hours or 3 Months 727

Warning and Safety Labels 727

Mast, Carriage, and Attachment 727

Lift Chains 727

Forks 728

Tires and Tire Pressure 728

Wheel Nuts, Drive and Steer Wheels 729

Hydraulic Tank Breather 729

Air Precleaner Dust Bowl 729

Fuel, Oil, and Coolant Leaks 729

Engine Air Intake Piping and Charge Air Piping 729

Coolant Hoses 729

Drive Belts 730

Engine Compartment 730

Radiator Sections for Engine Coolant, Charge Air Cooler, Transmi 730

Drive Axle and Differential 730

Windshield Washer Fluid 730

Hydraulic System Oil 730

Coolant Level 730

Engine Oil Level 731

Fuel Water Separator 731

Transmission Oil Level 731

LPG Crankcase Breather 731

Operator Restraint System (Seat Belt and Seat Rails) 732

Steering Column Latch 732

Operator Presence System (OPS) 732

Chain Sheave Bearings 732

Mast Pivot Pins 732

Carriage Pins, Fork Pins, and Carriage Sliding Surfaces 732

Maintenance Procedures Every 500 Hours or 3 Months 733

Tilt Cylinder Pivot Pins 733

Steering Axle Tie Rod Pins 733

Kingpins 733

Shafts for Air Brake Actuator Arms 733

Maintenance Procedures Every 500 Hours or 6 Months 733

Cab Air Filter 733

Header Hose Assembly 733

Air Compressor (Air Brakes Only) 733

Cooling Fan 733

Cummins Diesel and LPG Engine Oil 733

Engine Oil Filter 734

Diesel Fuel Filter 734

Maintenance Procedures Every 1000 Hours or 6 Months 734

Parking and Service Brakes 734

Coolant Quality 734

LPG Tank Hinges 734

Cab Door Hinges 734

LPG Vapor Fuel Filter 734

Wet Brake System Filter 735

Maintenance Procedures Every 1000 Hours or 1 Year 735

Transmission Oil 735

Transmission Oil Filter 735

Maintenance Procedures Every 1500 Hours or 6 Months 735

Drive Axle and Differential 735

Maintenance Procedures Every 2000 Hours or 1 Year 735

Transmission Clutch Calibration 735

Inching Pedal Sensor Calibration 735

Fan Belt and Tensioner 735

Fan Hub, Belt Hubs, Idler Pulley 736

Vibration Damper 737

Engine and Transmission Mounting 737

Spark Plug (LPG Engines Only) 737

LPG Liquid Fuel Filter 738

Brake System Accumulator 738

Pilot Valve Accumulator 738

Lift System Accumulator (Optional) 739

Drive Shaft 739

Spark Plug Wire (LPG Engine Only) 739

Maintenance Procedures Every 3000 Hours or 1 Year 740

Air Dryer Cartridge 740

Hydraulic System Oil and Filter 740

Hydraulic Pilot Valve Oil Screen 740

Maintenance Procedures Every 5000 Hours or 3 Years 741

Air Conditioning 741

Steering Wheel Hub Bearings 741

Maintenance Procedures Every 5000 Hours or 4 Years 741

Engine Valve Adjustment 741

Safety Procedures When Working Near Mast 741

Lift and Tilt System Leak Check 742

Lift System 742

Tilt System 743

Wheel and Tire Replacement 744

Remove Wheels From Lift Truck 744

Pneumatic Tires 744

Remove Tire From Wheel 744

Remove Tire From Two- and Four-Piece Wheel 745

Install Tire on Wheel 746

Install Tire on Two- and Four-Piece Wheel 746

Add Air to Tires 747

Solid Rubber Tires 748

Remove Tire From Wheel 748

Install Tire on Wheel 749

Wheels, Install 751

tables 689

Table 1 Daily Inspections − Condition Check 700

Table 2 Daily Inspections − Fluid Level Check 701

Table 3 Daily Inspections − Checks With the Engine Running 701

Table 4 Initial 100-Hour Check or Change 702

Table 5 Periodic Maintenance Schedule − Inspect and Adjust 703

Table 6 Periodic Maintenance Schedule − Lubricate 705

Table 7 Periodic Maintenance Schedule − Change 706

Table 8 Approved LPG Engine Oil Types 715

Table 9 Valve Adjustment Specifications 741

Table 10 Allowable Mast Movement from Internal Leakage 743

524298464 8000YRM1348 (07 2013) US EN 755

toc 755

Capacities and Specifications 755

Safety Precautions Maintenance and Repair 756

Counterweight Weights 759

Lift Truck Weights 759

Capacities 760

Engine Specifications 761

Hydraulic System 762

Electrical System 762

Tire Sizes 762

Mast Speeds 763

Torque Specifications, Cummins Diesel 764

Lubrication System 764

Torque Specifications, General 764

Transmission 764

Driveline and Axle 764

Counterweight 764

Differential 764

Brakes – Wet 764

Brakes – Dry 764

Steering 764

Wheel Nuts 765

Hydraulic System 765

Mast 765

Carriage 765

Tilt Cylinders 765

Wiper Arms, Front 765

524300812 0100YRM1349 (11 2015) US EN 769

General 773

Description 774

Air Cleaner 775

Remove 775

Install 775

Exhaust System 776

Remove 776

Install 776

Hood Assembly 777

Remove 777

Install 778

Hydraulic Tank 778

Remove 778

Inspect 780

Clean 781

Additional Preparations for Repair 781

Repair 781

Small Leaks 781

Large Leaks 782

Preparations for use After Repair 782

Install 782

Fuel Tank 783

Remove 783

Repair 787

Install 787

Cab Repair 787

Rear Cab Assembly 788

Bottom Cab Assembly 789

Raising and Lowering Cab 789

Raise Cab 789

Lower Cab 790

Cab Repair 790

Remove 790

Install 791

Engine 792

Remove 792

Install 796

Counterweight 799

General 799

Remove 799

Install 800

Cab 800

Remove 801

Install 802

Label Replacement 803

524300813 0700YRM1350 (05 2012) US EN 807

toc 807

Cooling System 807

Safety Precautions Maintenance and Repair 808

General 811

Cooling System Description 811

Cooling Cores 811

Fan and Shroud 812

Engine Cooling System 812

Water Pump 813

Thermostat 813

Expansion Tank And Radiator Cap 814

Cab Heater 814

Coolant 814

Charge Air Cooling System 816

Transmission Oil Cooling System 816

Hydraulic Oil Cooling System 816

Hydraulic Oil Cooling, D876/D877 Trucks 817

Hydraulic Oil Cooling, E876/E877 Trucks 817

Brake Cooling 818

Oil Filtration and Oil Cooling 818

Hydraulic Control System 818

Service and Repair 819

Cooling System Checks 819

Basic Checks 819

Coolant Quality Checks 819

Coolant Flow Checks 820

Thermostat 820

Water Pump 821

Cooling Core Efficiency 821

Cooling Core Flow Restrictions 821

Engine Leak Tests 822

External Leak Test 822

Check for Coolant Leak Into The Engine Oil Sump 823

Combustion Leak Test 823

Engine Cooling System Maintenance 824

Draining the Engine Cooling System 824

Filling the Engine Cooling System 825

Flushing the Engine Cooling System 825

Cleaning the Engine Cooling System 826

Remove and Replace Procedures 826

Drive Belt 826

Remove 826

Install 826

Belt Tensioner 826

Inspect 826

Remove 826

Install 827

Water Pump 827

Inspect 827

Remove 827

Install 827

Thermostat 828

Remove 828

Inspect 828

Install 828

Cooling Core Assembly 828

Removal 828

Cooling Cores 831

Disassembly 831

Assembly 831

Install 831

tables 807

Table 1 Limiting Values 815

Table 2 Thermostat Operating Temperatures 820

Table 3 Temperature Differences Between Core Entry and Core Exi 821

524300814 2200YRM1351 (04 2007) US EN 837

toc 837

Electrical System 837

Safety Precautions Maintenance and Repair 838

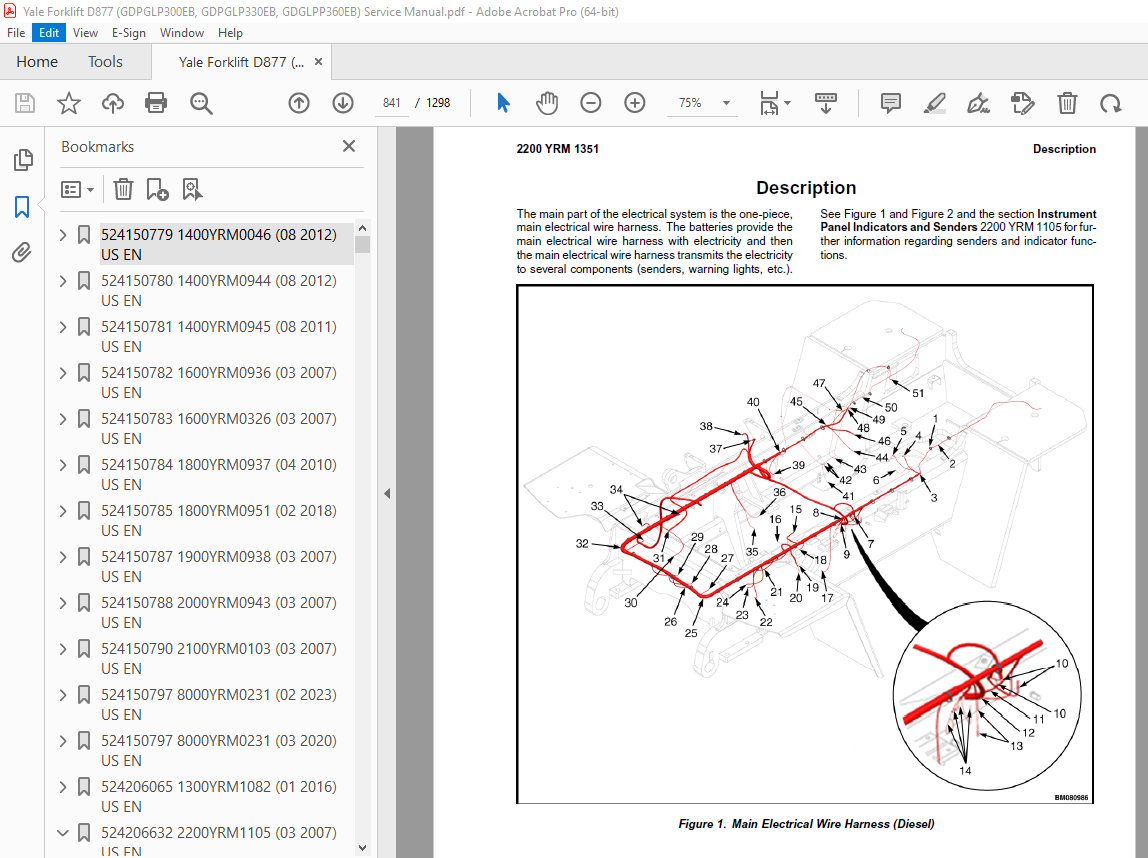

Description 841

Warning Devices 846

General 846

Description 847

Operator-Controlled Horn 847

Reverse Warning Horns/Lights 847

Warning Lights 847

Strobe Light 847

Brake Lights 849

Hazard Lights 849

Replace 849

General 849

Horns 849

Horn Relay 849

Light Assemblies 849

Flashing Unit 850

Meters, Senders, and Switches 850

General 850

524302733 1300YRM1356 (01 2016) US EN 863

Series Code / Model Designation Reference Table 867

General 867

Transmission Repair 867

Remove 867

Disassemble 871

Reverse and Second-Speed Clutch 901

Clean and Inspect 917

Housings 917

Oil Seals and Gaskets 918

Bearings 918

Gears and Shafts 918

Assemble 918

Reverse and Second-Speed Clutch 928

Install 969

Control Valve Removal and Installation 972

Remove 972

Install 972

Control Valve Components 973

Control Valve Disassemble and Assemble 973

Remove 973

Control Valve Cover 973

Control Valve Components 974

Install 974

Control Valve Components 974

Control Valve Cover 974

Transmission Frame Bracket 975

Torque Specifications 975

Torque Specifications for Lubricated or Plated Screw Threads 975

Troubleshooting 977

524304019 1300YRM1358 (01 2016) US EN 981

Series Code / Model Designation Reference Table 987

General 988

Description 988

General 988

Operation 991

Hydraulic Operation 991

1st/3rd Selector Valve 994

Cooling and Lubrication 996

Control System 997

General 998

APC200 Controller 998

Self Test 998

Protection Modes 998

Limp Home Mode 998

Shut Down Mode 998

Transmission Exceed Codes 999

Fault Codes 999

Description 999

Fault Log Mode 999

Access 999

Exit 1000

Clear 1000

Fault Rectification 1000

Hydraulic Control Valve 1002

Hydraulic Control Valve Repair 1004

Solenoid Replacement 1004

Pressure Check 1004

Pressure Specifications 1005

Pressure, Speed, and Temperature Sensors 1005

Pressure Switch 1010

Test 1010

Speed Sensor 1011

Test 1011

Temperature Sensors 1012

Test 1012

Transmission Test and Calibration 1013

Precautions 1013

Stall Test 1013

Description 1013

Stall Test Procedure 1013

Clutch Calibration 1014

Description 1014

Procedure 1015

Inching Calibration 1015

Description 1015

Brake and Inching Pedal Adjustment 1016

Inching Sensor Adjustment 1016

Inching Sensor Calibration 1017

Electrical Specifications 1017

APC200 Display information 1017

General 1018

General Information Group 1018

Fault Codes 1019

Indication of Protection Modes 1019

Test Function Group 1020

Digital Input Test 1022

Analog Input Test 1023

Speed Sensor Test 1024

Output Test 1025

Voltage Test 1026

Calibration Group 1028

Calibration Mode 1028

Clutch Filling Calibration 1028

Heat Up Mode 1029

Inching Sensor Calibration 1029

Inching Pedal Sensor Adjustment 1029

Inching Sensor Calibration 1029

TE-Userlink 1030

Description 1030

Connection 1030

1030

Diagrams, Schematics, or Arrangements 1030

550022606 1300YRM1435 (01 2016) US EN 1067

Series Code / Model Designation Reference Table 1071

General 1071

Transmission Exceed Codes 1071

Clutch Calibration Condition Messages 1071

Fault Codes During Clutch Calibration 1071

APC200 Fault Codes 1072

Limp Home Mode 1072

Shut Down Mode 1072

Pressure Feedback Sensor 1072

APC200 Fault Codes 1073

Transmission Exceed Codes 1073

Clutch Calibration Condition Messages 1077

Fault Codes During Clutch Calibration 1077

APC200 Fault Codes 1080

550033397 0100YRM1458 (04 2011) US EN 1107

toc 1107

Cab Heater (Prior to Oct 2008) 1107

Safety Precautions Maintenance and Repair 1108

Aurora Heater and Air Conditioner 1111

Heater System 1111

General 1111

Air Conditioning 1112

General 1112

Dryer 1113

Control Systems, Sensors, and Switches 1113

Heater System Repair 1115

Heater Assembly 1115

Access 1115

Remove 1115

Install 1115

Heater Assembly Parts, Replace 1116

Heater Core 1116

Remove 1116

Install 1116

Evaporator Core 1117

Remove 1117

Install 1117

Blower 1117

Remove 1117

Install 1117

Water Valve 1118

Remove 1118

Install 1118

Vent Door 1119

Remove 1119

Install 1119

Push/Pull Cable, Replace 1119

Water Valve Cable 1119

Remove 1119

Install 1120

Vent Door Cable 1120

Remove 1120

Install 1121

Electric-Operated Heater Control and Fan Control 1122

Remove 1122

Install 1122

Cable-Operated Heater Control and Air Control 1123

Remove 1123

Install 1123

Air Conditioning Switch 1123

Remove 1123

Install 1123

Technical Detail 1124

tables 1107

Table 1 Air Conditioning Specifications 1124

550033400 0100YRM1390 (12 2018) US EN 1127

Series Code / Model Designation Reference Table 1135

General 1135

Description of Operation 1137

Cab Structure 1137

Cab Tilt System 1137

Cab Tip-Up System 1139

Tilting the Cab 1140

Raising 1140

Lowering 1141

Remove and Install 1142

Cab Door Assembly 1142

Cab Door 1142

Remove 1142

Install 1142

Door Hinge 1143

Remove 1143

Install 1143

Door Latch 1144

Remove 1144

Install 1144

Door Handle 1144

Remove 1144

Install 1144

Door Release 1145

Remove 1145

Install 1145

Door Push Button 1145

Remove 1145

Install 1146

Cab Tilt System 1146

Electric Tilt Pump 1146

Remove 1146

Install 1146

Hand Tilt Pump 1146

Remove 1146

Install 1147

Cab Tilt Cylinder 1148

Remove 1148

Disassemble 1148

Clean 1150

Inspect 1150

Assemble 1150

Install 1151

Latch 1151

Remove 1151

Install 1152

Brake and Inching Pedal 1153

Remove 1153

Install 1153

Accelerator Pedal and Sensor 1154

Remove 1154

Install 1154

Adjust Sensor 1154

Seat Assembly 1154

Seat 1154

Remove 1154

Install 1155

Seat Cushion 1155

Remove 1155

Install 1156

Back Cushion 1156

Remove 1156

Install 1156

Seat Suspension Replacement 1156

Boot Replacement 1156

Power Assist Armrest 1180

Release Cable 1180

Remove 1180

Install 1180

Gas Spring 1180

Remove 1180

Install 1181

Joystick 1181

Remove 1181

Install 1181

Electrical Levers 1181

Remove 1181

Install 1182

Armrest Rocker Switches 1182

Remove 1182

Install 1182

Armrest Top Cover 1182

Remove 1182

Install 1182

Instrument Panel 1183

Key Switch 1183

Remove 1183

Install 1183

12V Power Socket 1183

Remove 1183

Install 1183

Electric-Operated Heat Control and Air Recirculation Control (Airco Only) 1184

Remove 1184

Install 1184

Cable-Operated Heater Control (Heater Only) 1185

Remove 1185

Install 1185

Air Conditioning Switch Replacement 1185

Instrument Panel Rocker Switches Replacement 1185

Parking Brake Switch 1186

Remove 1186

Install 1186

Indicator Display Replacement 1186

Instrument Panel Top Console 1186

Remove 1186

Install 1187

Steering Wheel and Column Assembly 1187

Steering Wheel and Horn 1187

Remove 1187

Install 1189

Steering Column Assembly 1189

Remove 1189

Install 1190

Adjustment Handle 1190

Remove 1190

Install 1190

Main Warning Lights 1191

Remove 1191

Install 1191

Shift Lever 1191

Remove 1191

Install 1191

Turn Signal Lever 1191

Remove 1191

Install 1191

Window Wipers 1192

Window Wiper Assembly Replacement 1192

Remove 1192

Install 1192

Window Wiper Motor Replacement 1192

Front Window Wiper Motor 1192

Install 1192

Rear Window Wiper Motor Assembly 1193

Remove 1193

Install 1193

Top Window Wiper Motor Assembly 1193

Remove 1193

Install 1193

Window Washer System 1194

Window Washer Reservoir and Pumps 1194

Remove 1194

Install 1194

Window Washer Hoses 1195

Hoses for Top and Rear Window 1195

Install 1196

Window Washer Spray Nozzles 1196

Front Window 1196

Remove 1196

Install 1196

Rear Window 1197

Remove 1197

Install 1197

Top Window 1197

Remove 1197

Install 1197

Window Replacement 1197

Front Window 1199

Remove 1199

Install 1199

Rear Window 1199

Remove 1199

Install 1199

Top Window 1200

Remove 1200

Install 1200

Door, Upper/Lower Window 1201

Remove 1201

Install 1201

Sliding Window and Sliding Tracks 1201

Remove 1201

Install 1203

Weather Strip Replacement 1203

Window Stopper Replacement 1203

Window Seal Replacement 1204

Sliding Window Frame 1204

Remove 1204

Install 1204

Floor Mat 1204

Front Floor Mat 1204

Remove 1204

Install 1205

Rear Floor Mat 1205

Remove 1205

Install 1206

Radio Console 1206

Remove 1206

Install 1206

Air Duct Replacement 1207

Remove Front 1207

Remove Rear 1207

Install 1208

Accessories 1208

Mirror Replacement 1208

Sunshade Replacement 1208

Top 1208

Rear 1209

Map Light Replacement 1209

Interior Fan Replacement 1209

Training Seat 1209

Field Installation 1209

Remove 1209

Label Replacement 1210

Checks and Adjustments 1210

Check Oil Level for Cab Tilt System 1210

Door Striker Pin Adjustment 1211

Brake Pedal Adjustment 1211

Dry Brake 1211

Wet Brake 1212

Inching Pedal Adjustment 1212

Inching Pedal Sensor Adjustment 1212

Sensor Adjustment Using Dana Dashboard Software 1212

Sensor Adjustment using the APC200 Display 1213

Sensor Adjustment for Trucks with ZF Transmission 1214

Inching Pedal Sensor Calibration 1214

Sensor Calibration using Dana Dashboard Software 1214

Sensor Calibration using APC200 Display 1214

Sensor Calibration for Trucks with ZF Transmission 1215

550088524 4000YRM1647 (07 2016) US EN 1219

Series Code / Model Designation Reference Table 1225

General 1225

Description And Operation 1225

Mast System 1225

Tilting 1225

Lifting 1226

Operation 1226

Pilot Operated Check Valves 1227

Gland Lubrication 1228

Emergency Lowering Valve 1228

Operation 1228

Lift Chains 1229

Elongation Through Wear 1229

Speed of Wear 1229

Plate Height Wear 1230

Lubrication 1230

Restoring The Oil Film 1230

Maintenance 1230

Maintaining The Presence of Oil 1231

Corrosion Protection 1231

Requirements for Chain Lubricant 1231

Load Rollers 1232

Bearing Blocks 1232

Carriage 1233

Standard Carriage with Manual Fork Positioning 1233

Standard Carriage with Hydraulic Fork Positioning 1233

Dual Function Side Shift and Fork Positioning (DFSSFP) Carriage 1234

Integral Side Shift 1234

Carriage Valve 1235

Alternating Pressure and Tank (P & T) 1235

Fixed Pressure and Tank (P & T) 1235

Flow Divider for Simultaneous Fork Positioning 1235

Valve for Dual Function with Side Shift and Fork Positioning (DFSSFP) 1237

Fixed Pressure and Tank System (Fixed P & T) 1239

Forks 1241

Safety Procedures When Working Near Mast 1242

Before Starting Repairs to the Hydraulic System, Always: 1243

Remove and Replace 1243

Forks 1243

Remove 1243

Install 1244

Fork Guide And Fork Pin 1245

Remove 1245

Install 1245

Carriage 1246

1246

Remove 1246

Install 1247

Carriage Bearing Blocks 1248

Remove 1248

Install 1249

1249

Carriage Load Rollers 1249

Replace 1249

1251

Side Shift Cylinder 1251

Remove 1251

Disassemble 1251

Clean And Inspect 1252

Assemble 1252

Install 1253

Fork Positioner Cylinder 1253

Remove 1253

Disassemble 1254

Clean and Inspect 1254

Assemble 1255

Install 1255

Carriage Valves 1255

Remove 1255

Install 1256

1256

Valve for Fixed P & T Systems 1256

Remove and Disassemble 1256

Clean and Inspect 1258

Assemble and Install 1258

Flow Divider for Simultaneous Fork Positioning Valve 1259

Restrictor Valve and Relief Valve Replacement 1259

Dual Function Valve for Side Shifting and Fork Positioning 1259

Solenoid Valve Replacement 1259

Relief Valve Replacement 1260

Remove 1260

Install 1260

Mast 1260

Lift Chains and Top Chain Anchor 1260

Remove 1260

Install 1260

Chain Anchor On Carriage 1261

Remove 1261

Install 1261

Chain Sheave 1262

Remove 1262

Install 1262

Header Hoses 1263

Remove 1263

Install 1265

Electric Mast Cable 1265

Remove 1265

Install 1265

Hose Sheave 1266

Remove and Disassemble 1266

Assemble and Install 1266

Mast Assembly 1267

Remove 1267

Disassemble 1269

Assemble 1270

Install 1271

Inner Mast Load Rollers 1273

Replace 1273

Mast Bearing Blocks 1274

Remove 1274

Install 1274

Lift Cylinders 1275

Remove 1275

Disassemble 1278

Clean and Inspect 1278

Assemble 1278

Install 1279

Tilt Cylinders 1280

Remove 1280

Disassemble 1281

Clean and Inspect 1281

Assemble 1281

Install 1282

Checks and Adjustments 1283

General Checks 1283

Mast Condition Check 1283

Mast Operation Check 1284

Counterbalance Valve Check (for E876 and E877 Only) 1284

Fork Inspection and Adjustment 1284

Lift Chain Inspection 1285

Lift Chain Lubricant Requirements 1286

Lift Chain Lubrication Procedure 1286

Leak Checks 1286

Mast Vertical Creep 1286

Mast Tilt Drift 1287

Adjustments 1287

Lift Cylinder Shimming 1287

Lift Chain and Fork Height Adjustment 1289

Header Hose Tension Adjustment 1291

Electric Mast Cable Tension Adjustment 1291

Counterbalance Valve Adjustment 1291

Tilt Cylinder Backward Tilt Angle Adjustment 1292

Mast Support Pad Adjustment 1292

Troubleshooting 1292

Introduction 1293

No Hydraulic Movement With Engine Running 1293

Initial Basic Check 1293

1294

Electrical Supply 1294

Hydraulic Supply 1294

Fault Code 1294

No Lowering Possible with Engine OFF 1295

Incorrect Movement 1295

Irregular (shaking) Movement

or

Slight Carriage Movement When Starting Engine

1295

Unequal Movement of Left And Right Tilt Cylinder 1295

Insufficient Lifting Speed 1295

Insufficient Lifting Capacity 1296

Incorrect Lowering Speed 1296

Lift Cylinder Creep 1296

Tilt Cylinder Creep 1296