$45.95

Yale Forklift D878 (GPGLPGDP135 VX, GPGLPGDP155VX) Service Manual PDF

Yale Forklift D878 (GPGLPGDP135 VX, GPGLPGDP155VX) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift D878 (GPGLPGDP135 VX, GPGLPGDP155VX) Service Manual – PDF DOWNLOAD

Language : English

Pages : 4758

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift D878 (GPGLPGDP135 VX, GPGLPGDP155VX) Service Manual – PDF DOWNLOAD

524150797 8000YRM0231 (02 2023) US EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797 8000YRM0231 (03 2020) US EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

524208014 2200YRM1097 (03 2020) US EN 43

Series Code / Model Designation Reference Table 47

Description 48

Distributor Ignition (DI) System 48

Crankshaft Position (CKP) Sensor 48

Camshaft Position (CMP) Sensor 48

Ignition Coil and Ignition Control Module (ICM) 48

Secondary Ignition Components 48

Spark Plugs and Wires 49

Spark Plug Wire Inspection 49

Spark Plug Wire Replacement 49

Remove 49

Install 50

Spark Plug Inspection 50

Usage 50

Inspection 50

Visual Inspection 52

Spark Plug Replacement 52

Remove 52

Install 52

Distributor Repair 53

Inspect 53

Overhaul 53

Disassemble 53

Assemble 56

Replace 57

Remove 57

Install Procedure 1 59

Install Procedure 2 60

Ignition Coil Replacement 61

Remove 61

Install 61

Ignition Control Module Replacement 62

Remove 62

Install 62

Starter Replacement 63

Remove 63

Install 66

Sensors and Switches 67

Gas and LPG Trucks 67

Crankshaft Position (CKP) Sensor 67

Remove 67

Install 67

Camshaft Position (CMP) Sensor 68

Remove 68

Install 70

Oil Pressure Sensor 70

Remove 70

Install 71

Manifold Absolute Pressure (MAP)/Manifold Air Temperature (MAT) Sensor 72

Remove 72

Install 72

Engine Coolant Temperature (ECT) Sensor 73

Remove 73

Install 74

Air Flow Restriction Switch 74

Remove 74

Install 75

Specifications and Special Tools 76

524221866 9000YRM1112 (10 2020) US EN 81

SECTION 9010 Operational Diagnostic Procedures 97

Group 05 – Operational Checkout 99

SECTION 9020 Engine 117

Group 10 – Principles of Operation 127

Group 30 – Observed Symptoms 325

Group 40 – Tests and Adjustments 427

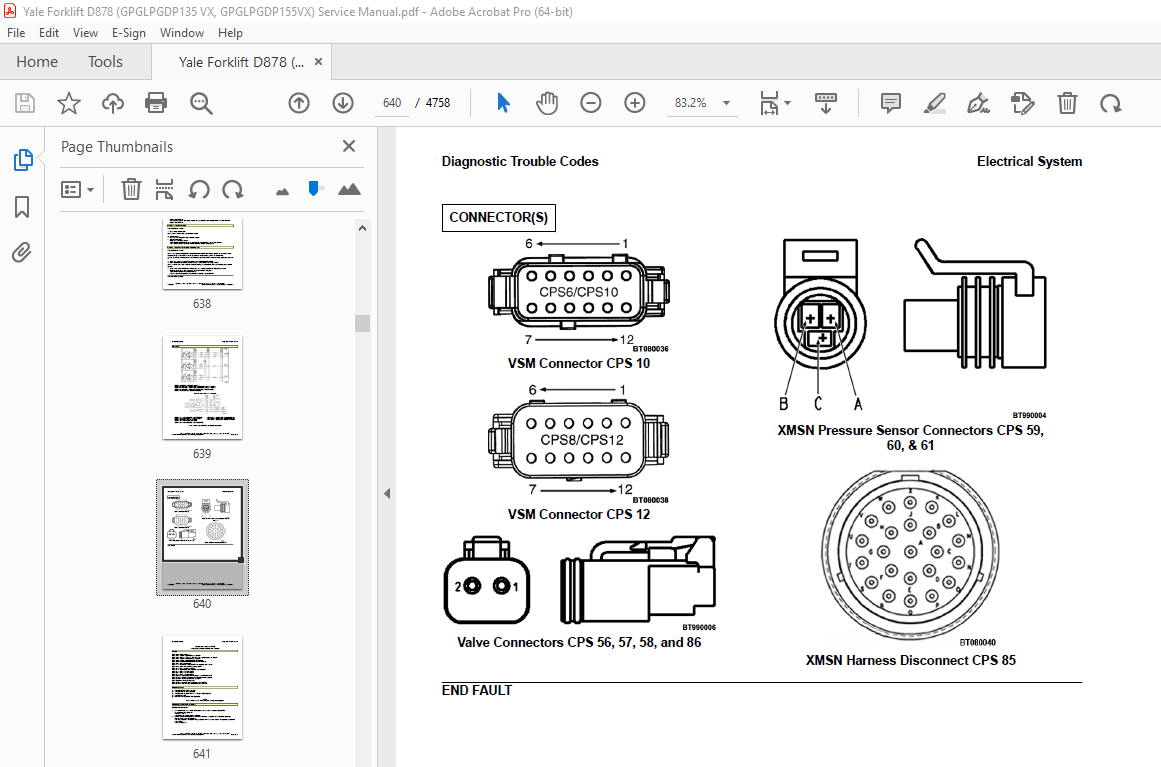

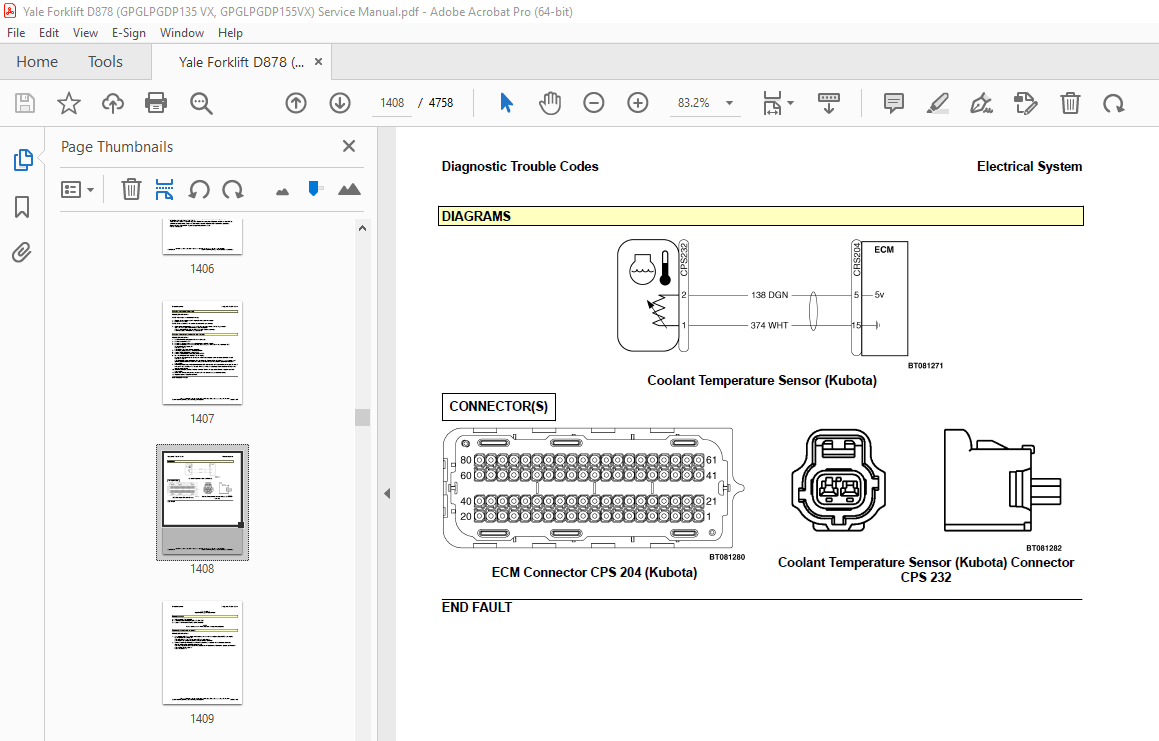

SECTION 9030 Electrical System 459

Group 03 – General Maintenance and Diagnostic Data 483

Group 10 – Principles of Operation 577

Group 20 – Diagnostic Trouble Codes 601

Group 30 – Observed Symptoms 1573

SECTION 9040 Drive Train 1629

Group 10 – Principles of Operation 1633

Group 30 – Observed Symptoms 1689

Group 40 – Tests and Adjustments 1739

SECTION 9050 Hydraulic Systems 1749

Group 10 – Principles of Operation 1753

Group 30 – Observed Symptoms 1811

Group 33 – Observed Symptoms-Gear Pump 1813

Group 35 – Observed Symptoms-Variable Displacement Pump (VDP) 1901

Group 40 – Tests and Adjustments 1945

Group 43 – Tests and Adjustments-Gear Pump 1947

Group 45 – Tests and Adjustments-Variable Displacement Pump (VDP) 1971

SECTION 9060 Operators Station 1989

Group 10 – Principles of Operation 1991

SECTION 9070 Front End (Mast) and Chassis 2027

Group 10 – Principles of Operation 2029

Group 30 – Observed Symptoms 2051

SECTION 9080 Supplementary Data 2109

Group 50 – Abbreviations and Acronyms 2111

Group 60 – Special Tools List 2119

Group 70 – Fault Mode Indicator Reference 2129

Group 80 – Supplier Specification Data 2131

524223757 0700YRM1123 (06 2016) US EN 2135

General 2139

Cooling System Checks 2139

Exhaust Leaks Into Cooling System 2139

Water Flow Restrictions in Radiator 2139

Radiator Hoses 2139

Water Pump 2140

Flushing the Cooling System 2140

Cooling System, Clean 2140

Radiator Replacement 2141

Radiator, Remove GC/GLC030VX,

GC/GLC035VX, GC/GLC040SVX

(C809); GLP/GDP16VX, GLP/GDP18VX,

GLP/GDP20SVX (GP/GLP/GDP030VX,

GP/GLP/GDP035VX, GP/GLP/GDP040SVX)

(C810); GLC20-35VX (GC/GLC040-070VX,

GC/GLC055SVX) (A910); GLC050LX

(A967); GLP/GDP20-35VX

(GP/GLP/GDP040-070VX) (B875);

GLP/GDP20-25LX (GLP/GDP050LX)

(A974); GLC40, 45, 55VX, GLC55SVX,

(GC/GLC080, 100, 120VX, GC/GLC080,

100VXBCS, GC/GLC120SVX,

GC/GLC120VXPRS) (E818, F818) AND

GLP/GDP40VX5/VX6, GLP/GDP45SVX5,

GLP/GDP45VX6, GLP/GDP50-55VX

(GP/GLP/GDP080, 090, 100, 110, 120VX)

(F813, G813, H813, J813) 2142

Radiator, Remove for Lift Trucks Models GC/GLC030VX, GC/GLC035VX,

GC/GLC040SVX (C809); GLP/GDP16VX,

GLP/GDP18VX, GLP/GDP20SVX

(GP/GLP/GDP030VX, GP/GLP/GDP035VX,

GP/GLP/GDP040SVX) (C810); GLC050LX

(A967) AND GLP/GDP20-25LX

(GLP/GDP050LX) (A974) Equipped with Oil Cooler 2157

Radiator, Remove for Lift Truck Models GLC/GDC60VX,

GLC/GDC60VX, (GC/GLC/GDC135VX,

GC/GLC/GDC135VX) (C879, D879, E879,

F879) 2160

Radiator , Remove for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX

(GP/GLP/GDP135VX, GP/GLP/GDP155VX)

(C878, D878, E878) and GLP/GDP80VX,

GLP/GDP80VX9, GLP/GDP90VX

(GLP/GDP170VX, GLP/GDP175VX36,

GLP/GDP190VX) (A909, B909) 2163

Radiator, Install for Lift Truck Models GC/GLC030VX,

GC/GLC035VX, GC/GLC040SVX

(C809); GLP/GDP16VX, GLP/GDP18VX,

GLP/GDP20SVX (GP/GLP/GDP030VX,

GP/GLP/GDP035VX, GP/GLP/GDP040SVX)

(C810); GLC20-35VX (GC/GLC040-070VX,

GC/GLC055SVX) (A910); GLC050LX

(A967); GLP/GDP20-35VX

(GP/GLP/GDP040-070VX) (B875);

GLP/GDP20-25LX (GLP/GDP050LX)

(A974); GLC40, 45, 55VX; GLC55SVX;

(GC/GLC080, 100, 120VX; GC/GLC080,

100VXBCS; GC/GLC120SVX;

GC/GLC120VXPRS) (E818, F818) and

GLP/GDP40VX5/VX6; GLP/GDP45SVX5,

GLP/GDP45VX6, GLP/GDP50-55VX

(GP/GLP/GDP080, 090, 100, 110, 120VX)

(F813, G813, H813, J813) 2170

Radiator, Install for Lift Truck Models GC/GLC030VX, GC/GLC035VX,

GC/GLC040SVX (C809); GLP/GDP16VX,

GLP/GDP18VX, GLP/GDP20SVX

(GP/GLP/GDP030VX, GP/GLP/GDP035VX,

GP/GLP/GDP040SVX) (C810); GLC050LX

(A967) and GLP/GDP20-25LX

(GLP/GDP050LX) (A974) Equipped with Oil Cooler 2175

Radiator, Install for Lift Truck Models GLC/GDC60VX,

GLC/GDC60VX, (GC/GLC/GDC135VX,

GC/GLC/GDC135VX) (C879, D879, E879,

F879) 2177

Radiator, Install for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 2180

Fan Assembly Replacement 2192

Fan Removal 2192

Inspect 2207

Fan Installation 2207

524223764 1600YRM1133 (07 2013) US EN 2213

toc 2213

Steering Axle 2213

Safety Precautions Maintenance and Repair 2214

General 2217

Steering Axle Assembly Repair 2219

Remove 2219

Disassemble 2220

Clean 2228

Inspect 2228

Assemble 2228

Install 2234

Spindles, Bearings, and Tie Rods Repair 2236

Spindles and Bearings 2236

GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), GLC40, 45, 55 2236

Remove 2236

Disassemble 2238

Clean 2239

Inspect 2239

Assemble 2239

Install 2240

Spindles and Bearings 2243

GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), GC/GLC030-035VX, GC 2243

Remove and Disassemble 2243

Assemble and Install 2244

Tie Rods 2244

GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), and GLC40, 45 2244

Remove 2244

Install 2245

Tie Rods 2246

GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), GC/GLC030-035VX, GC 2246

Remove 2246

Install 2252

Steering Cylinder Repair 2252

Remove and Disassemble 2252

Clean and Inspect 2253

Assemble and Install 2253

Torque Specifications 2254

524223766 1900YRM1136 (01 2022) US EN 2259

General 2263

Hydraulic Gear Pump Assembly 2264

Variable Displacement Pump Assembly 2265

Single Gear Pump Assembly Repair 2266

Remove 2266

Disassemble 2272

Clean 2274

Inspect 2274

Assemble 2274

Install 2274

Tandem Gear Pump Assembly 2279

Remove 2279

Disassemble 2280

Clean 2283

Inspect 2283

Assemble 2283

Install 2284

Gear Pump Specifications 2285

24 0 to 45 0 cc/rev – Variable Displacement Pump Repair 2291

Remove 2291

Disassemble 2301

Clean 2304

Inspect 2305

Assemble 2305

Install 2305

63 0 cc/rev – Variable Displacement Pump Repair 2310

Remove 2310

Disassemble 2313

Clean 2315

Inspect 2315

Assemble 2315

Install 2315

Variable Displacement Pump Checks and Adjustments (Single Pump) 2319

Margin Pressure Check 2319

Flow Compensator Adjustment 2320

Pressure Compensator Adjustment 2320

Variable Displacement Pump Checks and Adjustments (Tandem Pump) 2322

Variable Displacement Pump Specifications 2325

Torque Specifications 2327

Hydraulic Gear Pump 2327

Variable Displacement Pump 2328

Special Tools 2329

524223766 1900YRM1136 (11 2017) US EN 2331

General 2335

Hydraulic Gear Pump Assembly 2336

Variable Displacement Pump Assembly 2337

Single Gear Pump Assembly Repair 2337

Remove 2337

Disassemble 2344

Clean 2344

Inspect 2346

Assemble 2346

Install 2346

Tandem Gear Pump Assembly 2350

Remove 2351

Disassemble 2353

Clean 2355

Inspect 2355

Assemble 2355

Install 2356

Gear Pump Specifications 2356

24 0 to 45 0 cc/rev – Variable Displacement Pump Repair 2362

Remove 2362

Disassemble 2372

Clean 2375

Inspect 2375

Assemble 2375

Install 2376

63 0 cc/rev – Variable Displacement Pump Repair 2379

Remove 2379

Disassemble 2382

Clean 2382

Inspect 2382

Assemble 2384

Install 2384

Variable Displacement Pump Checks and Adjustments (Single Pump) 2386

Margin Pressure Check 2386

Flow Compensator Adjustment 2387

Pressure Compensator Adjustment 2387

Variable Displacement Pump Checks and Adjustments (Tandem Pump) 2388

Variable Displacement Pump Specifications 2391

Torque Specifications 2392

Hydraulic Gear Pump 2393

Variable Displacement Pump 2394

Special Tools 2394

524223767 2000YRM1137 (01 2017) US EN 2399

General 2405

Electro-Hydraulic Main Control Valve 2406

Description 2406

Remove 2414

Electro-Hydraulic Control Valve Sections 2419

General 2419

Outlet Control Valve Section 2419

Remove 2419

Disassemble 2420

Clean 2422

Inspect 2422

Assemble 2422

Install 2423

Auxiliary Control Valve Sections 2423

Remove 2423

Disassemble 2430

Clean 2431

Inspect 2432

Assemble 2432

Install 2434

Tilt Control Valve Section 2435

Remove 2435

Disassemble 2435

Clean 2441

Inspect 2441

Assemble 2441

Install 2442

Lift/Lower Control Valve Section 2443

Remove 2443

Disassemble 2443

Clean 2452

Inspect 2452

Assemble 2452

Install 2453

Mid-Inlet Section 2453

Remove 2453

Clean 2454

Inspect 2454

Install 2454

Install 2454

Electro Hydraulic Poppet Valve (EHPV) Pilot Pin Adjustment 2459

Lift Pilot Pin 2459

Lower Pilot Pin 2463

Abnormal/Erroneous EHPV Adjustment 2465

Manual Main Control Valve 2466

Description 2466

Remove 2470

OPS Solenoid Assembly 2478

General 2478

Remove 2479

Clean and Inspect 2482

Install 2482

Manual Control Valve Sections 2483

General 2483

Outlet Control Valve Section 2483

Remove 2483

Disassemble 2483

Clean 2486

Inspect 2486

Assemble 2486

Install 2487

Auxiliary Control Valve Sections 2487

Remove 2487

Disassemble 2487

Clean 2490

Inspect 2490

Assemble 2490

Install 2491

Lift/Tilt Control Valve Section 2491

Remove 2491

Disassemble 2491

Clean 2498

Inspect 2498

Assemble 2499

Install 2500

Mid-Inlet Section 2501

Remove 2501

Clean 2501

Inspect 2501

Install 2501

Install 2502

Pressure Relief Valve Check and Adjustment 2508

Primary Relief Valve 2509

Secondary Relief Valve 2513

Steering Control Unit Repair 2520

Steering Control Unit, Remove 2520

Steering Control Unit, Disassemble 2524

Steering Control Unit, Clean 2526

Steering Control Unit, Inspect 2526

Steering Control Unit, Assemble 2526

Relief Valve, Disassemble 2527

Relief Valve, Clean 2527

Relief Valve, Inspect 2528

Relief Valve, Assemble 2528

Steering Control Unit, Install 2528

524223769 2200YRM1128 (01 2023) US EN 2533

Series Code / Model Designation Reference Table 2541

General 2543

Deutsch Crimping Tool 2544

How to Strip a Wire for Use With Deutsch Crimping Tool 2544

How to Crimp With the Deutsch Crimping Tool 2545

Calibration Test for the Deutsch Crimping Tool 2547

Deutsch Connectors 2549

DT, DTM, and DTP Series Connectors 2549

HD Series Connectors 2592

Metri-Pack Connectors 2614

Remove and Install 2614

Micro-Pack Connectors 2617

Weather-Pack Connectors 2618

AMPSEAL Crimping Tools 2620

AMP Hand Crimping Tool With Certi-Crimp 2620

Description 2620

Stripping Wire for Use with AMP Hand Crimping Tool 2621

Insulation Crimp Adjustment 2622

Maintenance and Inspection for AMP Hand Crimping Tool 2622

AMP Hand Crimping Tool 2622

Crimp Height Inspection 2622

How to use AMP Hand Crimping Tool 2623

AMP Pro-Crimper II Tool 2623

Description 2623

Remove and Install Die Set and Locator Assembly 2624

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 2624

Contact Support Adjustment 2625

Crimp Height Adjustment 2626

Maintenance and Inspection Procedures 2626

PRO-CRIMPER II Tool 2626

Crimp Height Inspection 2626

How to Use AMP PRO-CRIMPER II Tool 2627

AMPSEAL Connector Assemblies 2628

Description for Plug Connector Assembly 2628

Seal Plug 2629

Contact Crimping 2629

Description for Plug Connector and Header Assembly 2634

Voltage Reading 2637

Seal Plug 2637

Contact Crimping 2637

AMP Superseal 1 5 Crimping Tools 2644

Mini Mic Receptacle and Tab Contacts 2644

Description 2644

Crimping Conditions and Measurements 2644

Insertion of Rubber Seal on Cable 2646

AMP Hand Application Tool 2651

Description 2651

Maintenance and Inspection 2651

Crimp Height Inspection 2651

Crimp Height Adjustment 2652

How to Use AMP Hand Application Tool 2652

AMP Pro-Crimper II Tool 2653

Description 2653

Remove and Install Die Set and Locator Assembly 2653

Adjustments 2654

Contact Support 2654

Crimp Height 2655

Inspections and Maintenance 2656

Crimp Height Inspection 2656

Visual Inspection 2656

Maintenance 2657

How to Use Pro-Crimper II Tool 2657

AMP Superseal 1 5 Connector Assemblies 2658

Description 2658

Repair and Maintenance 2665

Panel Mount Option 2665

AMP Fastin-Faston Hand Tools 2666

Description – AMP Double Action Hand Tool 2666

Maintenance and Inspection Procedures 2666

Daily Maintenance 2666

Periodic Tool Inspection 2667

Lubrication 2667

Visual Inspection 2667

Crimp Height Inspection 2667

Certi-Crimp Ratchet Inspection 2668

How to Use AMP Double Action Hand Tool 2669

Description – AMP Extraction Tool 2670

Maintenance and Inspection 2671

How to Use AMP Extraction Tool 2671

AMP Fastin-Faston Receptacles and Housings 2673

Description 2673

Wire Repair 2681

Wire Splicing Requirements 2681

Deutsch Jiffy Splice 2682

Twisted/Shielded Cable and Leads Repair 2688

Special Tools 2690

524223769 2200YRM1128 (07 2020) US EN 2699

Series Code / Model Designation Reference Table 2705

General 2708

Deutsch Crimping Tool 2708

How to Strip a Wire for Use With Deutsch Crimping Tool 2708

How to Crimp With the Deutsch Crimping Tool 2709

Calibration Test for the Deutsch Crimping Tool 2711

Deutsch Connectors 2713

DT, DTM, and DTP Series Connectors 2713

HD Series Connectors 2755

Metri-Pack Connectors 2778

Remove and Install 2778

Micro-Pack Connectors 2780

Weather-Pack Connectors 2781

AMPSEAL Crimping Tools 2783

AMP Hand Crimping Tool With Certi-Crimp 2783

Description 2783

Stripping Wire for Use with AMP Hand Crimping Tool 2783

Insulation Crimp Adjustment 2784

Maintenance and Inspection for AMP Hand Crimping Tool 2784

AMP Hand Crimping Tool 2784

Crimp Height Inspection 2784

How to use AMP Hand Crimping Tool 2785

AMP Pro-Crimper II Tool 2785

Description 2785

Remove and Install Die Set and Locator Assembly 2786

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 2787

Contact Support Adjustment 2787

Crimp Height Adjustment 2788

Maintenance and Inspection Procedures 2788

PRO-CRIMPER II Tool 2788

Crimp Height Inspection 2788

How to Use AMP PRO-CRIMPER II Tool 2789

AMPSEAL Connector Assemblies 2790

Description for Plug Connector Assembly 2790

Seal Plug 2791

Contact Crimping 2791

Description for Plug Connector and Header Assembly 2796

Voltage Reading 2798

Seal Plug 2798

Contact Crimping 2798

AMP Superseal 1 5 Crimping Tools 2805

Mini Mic Receptacle and Tab Contacts 2805

Description 2805

Crimping Conditions and Measurements 2805

Insertion of Rubber Seal on Cable 2807

AMP Hand Application Tool 2812

Description 2812

Maintenance and Inspection 2812

Crimp Height Inspection 2812

Crimp Height Adjustment 2813

How to Use AMP Hand Application Tool 2813

AMP Pro-Crimper II Tool 2814

Description 2814

Remove and Install Die Set and Locator Assembly 2815

Adjustments 2815

Contact Support 2815

Crimp Height 2816

Inspections and Maintenance 2817

Crimp Height Inspection 2817

Visual Inspection 2817

Maintenance 2818

How to Use Pro-Crimper II Tool 2818

AMP Superseal 1 5 Connector Assemblies 2819

Description 2819

Repair and Maintenance 2826

Panel Mount Option 2826

AMP Fastin-Faston Hand Tools 2827

Description – AMP Double Action Hand Tool 2827

Maintenance and Inspection Procedures 2827

Daily Maintenance 2827

Periodic Tool Inspection 2828

Lubrication 2828

Visual Inspection 2828

Crimp Height Inspection 2828

Certi-Crimp Ratchet Inspection 2829

How to Use AMP Double Action Hand Tool 2830

Description – AMP Extraction Tool 2831

Maintenance and Inspection 2831

How to Use AMP Extraction Tool 2832

AMP Fastin-Faston Receptacles and Housings 2833

Description 2833

Wire Repair 2840

Wire Splicing Requirements 2840

Deutsch Jiffy Splice 2841

Twisted/Shielded Cable and Leads Repair 2846

Special Tools 2849

524223770 2200YRM1130 (03 2020) US EN 2857

General 2861

Description 2861

Dash Display Menu Access 2861

Menu Navigation 2862

Standard Display 2862

Main Menu 2862

Passwords Menu 2863

Password Administration 2863

Add Password 2863

Delete Password 2864

Edit Password 2864

Other Password Functions 2865

Operator Passwords – Enable/Disable 2865

Password Time-Out Delay 2865

Passwords – Number Wrong to Disable 2866

Lockout Reset Password 2866

View Password Log 2867

View Versions 2868

VSM Versions 2868

Dash Display Versions 2869

Engine Controller Version 2870

Transmission (Xmsn) Controller Version 2871

Truck Serial Number 2872

Diagnostics 2873

View Fault Log 2873

Set Travel and Braking 2874

Speed Limit 2874

Acceleration Rate 2875

Auto-Deceleration Rate 2875

Set Power Reversal Rate 2876

Set Inching/Brake Overlap 2877

Setup Display Menu 2878

Set Operator Language 2878

Set Units 2879

Set Time Format (12/24 Hour) 2879

Set Daylight Saving Time 2879

Set Time 2882

Set Date Format 2883

Set Date 2883

Setup Hydraulics 2884

Return to Set Tilt Delay/On/Off 2884

Setup General Items 2885

Light Shutdown Time-Out 2885

Impact Sensor – Enable/Disable 2886

Impact Sensor – Soft Impact Settings 2887

Impact Sensor – Hard Impact Settings 2888

Adjust Impact Sensor Settings 2888

Initial Adjustment of Soft and Hard Impact Settings 2890

Readjustment of Soft and Hard Impact Settings 2890

Impact Sensor – Impact Alarm/Shutdown Reset 2891

Impact Sensor – Alarm Time Duration and Deactivation 2892

Impact Sensor – View Impact Event Log 2893

Engine Mode Indicator 2894

Generation 1 (ECO-eLo ONLY) 2894

Generation 2 2895

Operator Checklist 2896

Operator Checklist Off-On Mode 2896

Edit Operator Checklist 2896

Set Operator Checklist Expiration 2897

View Checklist Log 2897

Clear Operator Checklist Log 2898

Clear Operator Checklist Fault 2898

Calibrations 2899

Set Tilt Stop Point 2899

Calibrate Loaded Weight 2899

524223771 2200YRM1131 (03 2020) US EN 2901

Series Code / Model Designation Reference Table 2907

General 2909

Description 2909

Dash Display Menu Access 2909

Menu Navigation 2910

Main Menu 2910

Passwords 2911

Adding Passwords 2911

Hourmeters 2913

View Versions 2914

VSM Versions 2914

Dash Display Versions 2915

Engine Controller Version 2916

Transmission (Xmsn) Controller Version 2917

Truck Serial Number 2918

Truck Configuration 2919

Diagnostics 2920

Clear Fault Log 2920

View Fault Log 2921

No-Run Data Display 2922

Engine Accelerator and Throttle Data Display 2922

Engine Speeds and Governor Data Display 2923

Engine Fuel and Emissions Data Display 2924

Engine General Data Display 2926

XMSN/Brake Data Display 2927

Hydraulic Data Display 2930

General Truck Data Display 2932

Set Travel and Braking 2933

Speed Limit 2933

Acceleration Rate 2934

Auto-Deceleration Rate 2935

Set Power Reversal Rate 2935

Set Inching/Brake Overlap 2936

Setup Hydraulics 2936

Lift Maximum Speed 2937

Lower Maximum Speed 2937

Tilt Maximum Speed 2938

Auxiliary Function One, Direction A, Maximum Speed 2940

Auxiliary Function One, Direction B, Maximum Speed 2942

Auxiliary Function Two, Direction A, Maximum Speed 2942

Auxiliary Function Two, Direction B, Maximum Speed 2943

Auxiliary Function Three, Direction A, Maximum Speed 2944

Auxiliary Function Three, Direction B, Maximum Speed 2944

Lift/Lower Ramp Rate 2945

Hydraulic Auxiliary Ramp Rate 2945

Return to Set Tilt Delay/On/Off 2946

Hydraulic Input Device 2947

Auxiliary Solenoid 2947

Dual Function 2948

Setup Display 2949

Set Service Language 2949

Setup General Items 2949

Motion Alarm Activation Type 2950

Light Shutdown Time-Out 2951

Restore Default Settings 2951

Restore Engine Controller Default Calibration 2952

Impact Sensor – Enable/Disable 2952

Impact Sensor – Soft Impact Settings 2953

Impact Sensor – Hard Impact Settings 2954

Adjust Impact Sensor Settings 2955

Initial Adjustment of Soft and Hard Impact Settings 2957

Readjustment of Soft and Hard Impact Settings 2957

Impact Sensor – Impact Alarm/Shutdown Reset 2958

Impact Sensor – Alarm Time Duration and Deactivation 2959

Impact Sensor – View Impact Event Log 2960

Engine Mode Indicator 2960

Generation 1 (ECO-eLo ONLY) 2960

Generation 2 2961

Diesel Particulate Filter (DPF) Display 2962

General Description 2962

Passive Regeneration Only 2962

Regeneration Level 0 2962

Auto/Active Regeneration Inhibited 2963

Auto/Active Regeneration 2963

Regeneration Level 1 2963

Parked Regeneration Request 2964

Regeneration Level 2 2964

Warning Level 2964

Regeneration Level 3 2964

Service Level 2965

Regeneration Level 4 2965

Display, Diesel Particulate Filter (DPF), Revised 2965

Operator Interface 2965

Refer to Operator Manual 2965

CAN Communication Lost 2966

Passive Regeneration Only 2966

Regeneration Level 0 2966

Auto/Active Regeneration Inhibited 2966

Auto/Active Regeneration 2967

Regeneration Level 1 2967

Idle-up Auto/Active Regeneration 2967

Parked Regeneration Request 2967

Regeneration Level 2 2967

Warning Level 2969

Regeneration Level 3 2969

Service Level 2969

Regeneration Level 4 2969

Diesel Particulate Filter (DPF) Display 2-3 5T ICE Stage V 2969

Display, Diesel Particulate Filter (DPF), Stage V Engine 2969

Operator Interface 2970

Refer to Operator Manual 2970

CAN Communication Lost 2970

Passive Regeneration Only 2970

Regeneration Level 0 2970

Auto/Active Regeneration Inhibited 2971

Auto/Active Regeneration 2971

Regeneration Level 1 2971

Idle-up Auto/Active Regeneration 2972

Parked Regeneration Request 2972

Regeneration Level 2 2972

Warning Level 2973

Regeneration Level 3 2973

Service Level 2974

Regeneration Level 4 2974

Stage V Content 2974

Emissions System Malfunction 2974

Ash Load 2974

Diesel Particulate Filter (DPF) Display with Diesel Exhaust Fluid (DEF) 2975

Operator Interface 2975

Refer to Operator Manual 2975

CAN Communication Lost 2976

Passive Regeneration Only 2976

Regeneration Level 0 2976

Auto/Active Regeneration Inhibited 2976

Auto/Active Regeneration 2977

Regeneration Level 1 2977

Idle-up Auto/Active Regeneration 2977

Parked Regeneration Request 2977

Regeneration Level 2 2977

Warning Level 2979

Regeneration Level 3 2979

Service Level 2979

Regeneration Level 4 2979

Calibrations 2980

Calibrate Transmission Valve 2982

Set Tilt Stop Point 2982

Calibrate Loaded Weight 2982

Calibrate Travel Speed Sensor 2983

Calibrate Mazda LP and Gas Accelerator Pedal 2983

524223772 2200YRM1142 (01 2020) US EN 2985

General 2995

Display Switch Cluster 2998

Remove 2998

Install 3001

Direction Control and Turn Signal Levers 3001

Remove 3001

Install 3003

Key Switch 3003

Remove 3003

Install 3004

Display Switch Cluster Panel Bezel and Overlay 3004

Remove 3004

Install 3004

Steering Column Repair 3004

Remove 3004

Disassemble 3007

Assemble 3007

Install 3007

Sensors and Switches 3008

General 3008

Dash and Kick Panel, Remove and Install 3008

Remove 3008

Install 3009

Accelerator Pedal Position Sensor 3010

Remove 3010

Install 3013

Brake Fluid Level Switch 3014

Remove 3014

Install 3016

Service Brake Pedal Position Sensor 3017

Remove 3017

Install 3020

Parking Brake Sensor 3021

Remove 3021

Install 3022

Service Brake Pressure Sensor 3023

Remove 3023

Install 3025

Accumulator Pressure Switch For Lift Truck Models GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 3026

Remove 3026

Install 3026

Sensor Microswitch (Foot Directional Control Pedal) 3027

Remove 3027

Install 3030

Low Coolant Level Sensor 3031

Remove 3031

Install 3034

Fuel Level Sensor, Gas and Diesel Engines Only 3035

Remove 3035

Install 3036

Armrest Switch 3036

Remove 3036

Install 3038

Seat Sensor (Operator Presence System) 3038

Non-Suspension and Semi-Suspension Seats; For Lift truck Models GC/GLC030-35VX, GC/GLC040SVX (C809), GLP/GDP16-8VX, GLP/GDP20SVX (GP/GLP/GDP030-35VX, GP/GLP/GDP040SVX) (C810), GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), GLC40-55VX; GLC55SVX; (GC/GLC080-120VX; GC/GLC080-100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080-120VX) (F813, G813, H813, J813), and GLC/GDC60-70VX (GC/GLC/GDC135-155VX) (C879, D879, E879, F879) 3038

Remove 3038

Install 3039

Non-Suspension Seats; Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3039

Remove 3039

Install 3040

Full Suspension Seats; All Lift Truck Models 3040

Remove 3040

Install 3040

Hood Shut Off Switch 3040

Remove 3040

Install 3043

Remote Key Switch 3044

Remove 3044

Install 3044

Hydraulic Filter Pressure Switch 3045

Remove 3045

Install 3047

Transmission Speed Sensor 3047

Remove 3047

Install 3050

Transmission Pressure Sensors 3051

Remove 3051

Install 3053

Transmission Temperature Sensor 3054

Remove 3054

Install 3056

Engine Speed Sensor 3058

Remove 3058

Install 3058

Intermediate Speed Sensor 3059

Remove 3059

Install 3059

Return to Set Tilt (Tilt Angle) Sensor 3059

Lift Truck Models GLC20-35VX (GC/GCL040-070VX, GC/GLC055SVX) (A910); GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP30VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) 3059

Remove 3059

Install 3060

Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878), GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813), GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 3061

Remove 3061

Install 3062

Rear Horn Button Switch 3062

Remove 3062

Install 3063

Impact Sensor 3064

Lift Truck Models GC/GLC030-35VX, GC/GLC040SVX (C809), GLP/GDP16-18VX, GLP/GDP20SVX (GP/GLP/GDP030-35VX, GP/GLP/GDP040SVX) (C810), GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), GLC40-55VX; GLC55SVX; (GC/GLC080-120VX; GC/GLC080-100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080-120VX) (F813, G813, H813, J813), and GLC/GDC60-70VX (GC/GLC/GDC135-155VX,) (C879, D879, E879, F879) 3064

Remove 3064

Install 3067

Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878), GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 3067

Remove 3067

Install 3068

Load Weight Sensor 3069

Remove 3069

Install 3070

Engine and Fuel Sensors and Switches, Gas and LPG Trucks Equipped with Mazda EnginesFE and F2 3071

Engine and Fuel Sensors and Switches, Gas and LPG Trucks Equipped with GM Engines 3071

Crankshaft Position (CKP) Sensor 3071

Camshaft Position (CMP) Sensor 3071

Oil Pressure Sensor 3071

Manifold Absolute Pressure (MAP)/Manifold Air Temperature (MAT) Sensor 3071

Engine Coolant Temperature (ECT) Sensor 3072

Air Flow Restriction Switch 3072

Remove for GM 2 4L Gas and LPG Trucks 3072

Install for GM 2 4L Gas and LPG Trucks 3072

Oxygen Sensor 3073

Remove 3073

Install 3076

Engine and Fuel Sensors and Switches, PSI 4 3L LPG Engine 3077

Crankshaft Position (CKP) Sensor 3077

Camshaft Position (CMP) Sensor 3077

Oil Pressure Sensor 3077

Manifold Absolute Pressure (MAP)/Manifold Air Temperature (MAT) Sensor 3077

Engine Coolant Temperature (ECT) Sensor 3077

Air Flow Restriction Switch 3077

Oxygen Sensor 3077

Engine and Fuel Switches, GM 2 4L LPG Trucks Only 3077

Low LPG Pressure Switch 3077

Engine and Fuel Sensors and Switches, Yanmar Diesel Trucks 3078

Air Filter Restriction Switch 3078

Remove 3078

Install 3078

Oil Pressure Sensor 3078

Remove 3078

Install 3078

Engine Speed Sensor 3078

Remove 3078

Install 3078

Engine Coolant Temperature (ECT) Sensor 3078

Remove 3078

Install 3078

Throttle Position Sensor (TPS) 3081

Remove 3081

Install 3082

Fuel/Water Separator Sensor 3082

Remove 3082

Install 3082

Glow Plug Relay 3083

Remove 3083

Install 3085

Engine and Fuel Sensors and Switches, Cummins Diesel Engines 3085

Air Filter Restriction Switch 3085

Remove 3085

Install 3085

Engine Oil Pressure Sensor 3090

Remove 3090

Install 3090

Engine Speed Sensor 3090

Remove 3090

Install 3091

Engine Coolant Temperature (ECT) Sensor 3091

Remove 3091

Install 3092

Throttle Position Sensor (TPS) (Cummins 4 5L Only) 3093

Remove 3093

Install 3093

Fuel/Water Separator Sensor 3094

Remove 3094

Install 3094

Engine and Fuel Sensors and Switches, Kubota 3 8L Diesel Engine Without DPF 3095

Intake Air Temperature Sensor 3095

Remove 3095

Install 3096

Intake Air Pressure Sensor 3096

Remove 3096

Install 3096

Air Inlet Heater 3096

Remove 3096

Install 3097

Engine Oil Pressure Sensor 3097

Remove 3097

Install 3097

Engine Coolant Temperature (ECT) Sensor 3097

Remove 3097

Install 3097

Crankshaft Position Sensor 3098

Remove 3098

Install 3098

Adjust Shim Procedure 3099

Camshaft Position Sensor 3100

Remove 3100

Install 3100

Air Flow Restriction Sensor 3101

Remove 3101

Install 3101

Fuel/Water Separator 3101

Remove 3101

Install 3102

Engine and Fuel Sensors and Switches, Kubota 3 8L Diesel Engine With DPF 3102

Intake Air Temperature Sensor 3106

Remove 3106

Install 3107

Boost Sensor 3107

Remove 3107

Install 3108

Throttle Valve Assembly and Air Intake Heater 3108

Remove 3108

Install 3108

Engine Coolant Temperature (ECT) Sensor 3109

Remove 3109

Install 3109

Engine Oil Pressure Sensor 3109

Remove 3109

Install 3110

Crankshaft Position Sensor 3110

Remove 3110

Install 3110

Adjust Shim Procedure 3111

Camshaft Position Sensor 3112

Remove 3112

Install 3113

Differential Pressure Sensor 3113

Remove 3113

Install 3113

Mass Air Flow Sensor 3114

Remove 3114

Install 3115

Fuel/Water Separator 3115

Remove 3115

Install 3116

Engine and Fuel Sensors and Switches, Kubota 3 6L Diesel Engine 3116

Engine Coolant Temperature (ECT) Sensor 3117

Remove 3117

Install 3117

Throttle Position Sensor 3118

Engine Oil Pressure Sensor 3118

Remove 3118

Install 3118

Engine Speed Sensor 3118

Remove 3118

Install 3118

Fuel Shut Off Solenoid 3118

Remove 3118

Install 3118

Vehicle System Manager (VSM) 3119

General 3119

VSM Replacement 3119

Remove 3119

Install 3121

Programming a New VSM and/or Display Switch Cluster 3121

General 3121

PC Service Tool Software 3122

Data Transferring 3122

New VSM 3122

New (Blank) Display Switch Cluster 3122

Used (Non-Blank) Display Switch Cluster 3122

Power Distribution Module (PDM) and Component Parts 3124

Remove 3124

PDM as a Unit 3124

Install 3128

PDM as a Unit 3128

Remove and Install 3129

PDM Component Parts 3129

Transmission Control Unit 3129

Remove 3129

Install 3133

Battery 3135

Remove 3135

Install 3135

Lights 3136

Work Lights (Front and Rear) 3136

Remove 3136

Install 3136

Strobe Light 3137

Remove 3137

Install 3137

LED Tail, Backup, and Brake Lights 3138

Remove 3138

Install 3139

Front Marker/Turn Signal Lights 3140

Replacing Whole Front Marker/Turn Signal Light Assembly 3140

Remove 3140

Install 3140

Replacing Just the Front Marker/Turn Signal Light LED Light Lens 3141

Remove 3141

Install 3141

Diesel Particulate Filter (DPF) Display 3141

Remove 3141

Clean and Inspect 3142

Install 3142

Electronic-Hydraulic Controls – Generation 1 3143

E-Hydraulic Controls – Test 3143

Mini-Levers 3143

Full Stroke Test 3143

Function Returns to Neutral Test 3143

Push Button Switch 3143

General 3144

Mini-Lever Replacement 3144

Remove 3144

Clean and Inspect 3145

Install 3145

Push Button Switch Replacement 3146

Remove 3146

Install 3148

Mini-Lever Module (MLM) 3148

Remove 3148

Install 3148

Joystick 3149

Remove and Disassemble 3149

Inspect 3149

Assemble and Install 3149

Electronic-Hydraulic Controls – Generation 2, Before January, 2020 3150

General 3150

Mini-levers, Remove and Install 3150

Armrest Assembly 3151

Remove 3151

Install 3154

Horn Button 3154

Remove 3154

Install 3154

Direction Control Switch 3155

Remove 3155

Install 3155

push (override) buttons and Toggle Switch 3155

Remove 3156

Install 3157

Joystick 3158

Remove and Disassemble 3158

Inspect 3158

Assemble and Install 3158

Joystick Armrest Slider Assembly 3159

Remove 3159

Install 3160

Electronic-Hydraulic Controls, After January, 2020 3160

E-Hydraulic Controls – TEST 3160

Mini-Levers 3160

Full Stroke Test 3160

Function Returns to Neutral Test 3160

Push (Override) Button 3161

General 3161

Mini-levers, Remove and Install 3161

Armrest Assembly 3162

Remove 3162

Install 3165

Horn Button 3165

Remove 3165

Install 3165

Direction Control Switch 3165

Remove 3165

Install 3166

Push (Override) buttons and Toggle Switch 3166

Remove 3167

Install 3169

Special Tools 3170

524223780 8000YRM1134 (03 2020) US EN 3173

Series Code / Model Designation Reference Table 3179

Description 3181

Proc_Cal_001: Service Password Entry 3183

When to Perform 3183

Why Perform 3183

How to Perform 3183

Proc_Cal_002: Hydraulic Valve Calibration Warm Up and Air Bleed 3184

When to Perform 3184

Calibration Order 3184

Why Perform 3184

How to Perform 3185

Proc_Cal_003: Save and Exit 3186

When to Perform 3186

Why Perform 3186

How to Perform 3186

Proc_Cal_004: Lift Valve Output Threshold 3187

When to Perform 3187

Calibration Order 3187

Why Perform 3187

How to Perform 3188

Proc_Cal_005: Lower Valve Output Threshold 3190

When to Perform 3190

Calibration Order 3190

Why Perform 3190

How to Perform 3190

Proc_Cal_006: Tilt Back Valve Output Threshold 3193

When to Perform 3193

Calibration Order 3193

Why Perform 3193

How to Perform 3193

Proc_Cal_007: Tilt Forward Valve Output Threshold 3196

When to Perform 3196

Calibration Order 3196

Why Perform 3196

How to Perform 3196

Proc_Cal_008: Aux 1 Dir A Valve Output Threshold 3199

When to Perform 3199

Calibration Order 3199

Why Perform 3199

How to Perform 3199

Proc_Cal_009: Aux 1 Dir B Valve Output Threshold 3202

When to Perform 3202

Calibration Order 3202

Why Perform 3202

How to Perform 3202

Proc_Cal_010: Aux 2 Dir A Valve Output Threshold 3205

When to Perform 3205

Calibration Order 3205

Why Perform 3205

How to Perform 3205

Proc_Cal_011: Aux 2 Dir B Valve Output Threshold 3208

When to Perform 3208

Calibration Order 3208

Why Perform 3208

How to Perform 3208

Proc_Cal_012: Aux 3 Dir A Valve Output Threshold 3211

When to Perform 3211

Calibration Order 3211

Why Perform 3211

How to Perform 3211

Proc_Cal_013: Aux 3 Dir B Valve Output Threshold 3214

When to Perform 3214

Calibration Order 3214

Why Perform 3214

How to Perform 3214

Proc_Cal_014: Load Weight Zero Point 3218

When to Perform 3218

Calibration Order 3218

Why Perform 3218

How to Perform 3218

Proc_Cal_015: Loaded Weight Calibration 3220

When to Perform 3220

Calibration Order 3220

Why Perform 3220

How to Perform 3220

Proc_Cal_016: Transmission Valve Calibration 3223

Applicable System/Option 3223

When to Perform 3223

Calibration Order 3223

Why Perform 3223

How to Perform 3223

Proc_Cal_016A: Transmission Valve Calibration-Electronic Extended Function 3225

Applicable System/Option 3225

When to Perform 3225

Calibration Order 3225

Why Perform 3225

How to Perform 3225

Proc_Cal_016B: Trans Valve Calibration-Electronic and Electronic Extended Function 3227

Applicable System/Option 3227

When to Perform 3227

Calibration Order 3227

Why Perform 3227

How to Perform 3228

Proc_Cal_019: Mazda LP and Gas Accelerator Pedal Adjustment 3229

Required Tools 3229

When to Perform 3229

Calibration Order 3229

Why Perform 3230

How to Perform 3230

Proc_Cal_025: Hydraulic Valve Pressure Gage Installation 3231

When to Perform 3231

Why Perform 3231

How to Perform 3231

Proc_Cal_026: Travel Speed Calibration 3233

When to Perform 3233

Calibration Order 3233

Why Perform 3233

How to Perform 3233

524223780 8000YRM1134 (05 2022) US EN 3237

Series Code / Model Designation Reference Table 3243

Description 3246

Proc_Cal_001: Service Password Entry 3248

When to Perform 3248

Why Perform 3248

How to Perform 3248

Proc_Cal_002: Hydraulic Valve Calibration Warm Up and Air Bleed 3249

When to Perform 3249

Calibration Order 3249

Why Perform 3249

How to Perform 3249

Proc_Cal_003: Save and Exit 3251

When to Perform 3251

Why Perform 3251

How to Perform 3251

Proc_Cal_004: Lift Valve Output Threshold 3252

When to Perform 3252

Calibration Order 3252

Why Perform 3252

How to Perform 3252

Proc_Cal_005: Lower Valve Output Threshold 3255

When to Perform 3255

Calibration Order 3255

Why Perform 3255

How to Perform 3255

Proc_Cal_006: Tilt Back Valve Output Threshold 3258

When to Perform 3258

Calibration Order 3258

Why Perform 3258

How to Perform 3258

Proc_Cal_007: Tilt Forward Valve Output Threshold 3261

When to Perform 3261

Calibration Order 3261

Why Perform 3261

How to Perform 3261

Proc_Cal_008: Aux 1 Dir A Valve Output Threshold 3264

When to Perform 3264

Calibration Order 3264

Why Perform 3264

How to Perform 3264

Proc_Cal_009: Aux 1 Dir B Valve Output Threshold 3267

When to Perform 3267

Calibration Order 3267

Why Perform 3267

How to Perform 3267

Proc_Cal_010: Aux 2 Dir A Valve Output Threshold 3270

When to Perform 3270

Calibration Order 3270

Why Perform 3270

How to Perform 3270

Proc_Cal_011: Aux 2 Dir B Valve Output Threshold 3273

When to Perform 3273

Calibration Order 3273

Why Perform 3273

How to Perform 3273

Proc_Cal_012: Aux 3 Dir A Valve Output Threshold 3276

When to Perform 3276

Calibration Order 3276

Why Perform 3276

How to Perform 3276

Proc_Cal_013: Aux 3 Dir B Valve Output Threshold 3279

When to Perform 3279

Calibration Order 3279

Why Perform 3279

How to Perform 3279

Proc_Cal_014: Load Weight Zero Point 3282

When to Perform 3282

Calibration Order 3282

Why Perform 3282

How to Perform 3282

Proc_Cal_015: Loaded Weight Calibration 3284

When to Perform 3284

Calibration Order 3284

Why Perform 3284

How to Perform 3284

Proc_Cal_016: Transmission Valve Calibration 3287

Applicable System/Option 3287

When to Perform 3287

Calibration Order 3287

Why Perform 3287

How to Perform 3287

Proc_Cal_016A: Transmission Valve Calibration-Electronic Extended Function 3289

Applicable System/Option 3289

When to Perform 3289

Calibration Order 3289

Why Perform 3289

How to Perform 3289

Proc_Cal_016B: Trans Valve Calibration-Electronic and Electronic Extended Function 3292

Applicable System/Option 3292

When to Perform 3292

Calibration Order 3292

Why Perform 3292

How to Perform 3292

Proc_Cal_019: Mazda LP and Gas Accelerator Pedal Adjustment 3295

Required Tools 3295

When to Perform 3295

Calibration Order 3295

Why Perform 3295

How to Perform 3295

Proc_Cal_025: Hydraulic Valve Pressure Gage Installation 3297

When to Perform 3297

Why Perform 3297

How to Perform 3297

Proc_Cal_026: Travel Speed Calibration 3299

When to Perform 3299

Calibration Order 3299

Why Perform 3299

How to Perform 3299

524262275 0900YRM1242 (04 2018) US EN 3303

General 3309

Hoses Replacement 3309

LPG Tank and Bracket Replacement 3310

LPG Tank, Lift Truck Models GLC40, 45, 55VX; GLC55SVX; GLC080, 100, 120VX; GLC080, 100VXBCS; GLC120SVX; GLC120VXPRS) (E818), GLP40VX5/VX6; GLP45SVX5, GLP45VX6; GLP50-55VX (GLP080, 90, 100, 110, 120VX) (F813, G813, H813), and GLC60VX, GLC70VX (GLC135VX, GLC155VX) (D879) 3310

Remove 3310

Install 3313

LPG Tank Bracket, Lift Truck Models GLC40, 45, 55VX; GLC55SVX; GLC080, 100, 120VX; GLC080, 100VXBCS; GLC120SVX; GLC120VXPRS) (E818), GLP40VX5/VX6; GLP45SVX5, GLP45VX6; GLP50-55VX (GLP080, 90, 100, 110, 120VX) (F813, G813, H813), and GLC60VX, GLC70VX (GLC135VX, GLC155VX) (D879) 3314

Remove 3314

Install 3314

LPG Tank Bracket Alignment Pin, Lift Truck Models GLC40, 45, 55VX; GLC55SVX; GLC080, 100, 120VX; GLC080, 100VXBCS; GLC120SVX; GLC120VXPRS) (E818), GLP40VX5/VX6; GLP45SVX5, GLP45VX6; GLP50-55VX (GLP080, 90, 100, 110, 120VX) (F813, G813, H813), and GLC60VX, GLC70VX (GLC135VX, GLC155VX) (D879) 3314

Remove 3314

Install 3316

LPG Tank, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (D878) 3317

Remove 3317

Install 3319

LPG Tank Bracket, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (D878) 3319

Remove 3319

Install 3319

High Pressure Fuel Filter Unit Repair 3319

Fuel Filter Element 3320

Remove 3320

Clean/Inspect 3321

Install 3321

Fuel Filter Housing 3321

Remove 3321

Disassemble 3322

Assemble 3322

Install 3322

Electronic Throttle Body Repair 3323

Remove 3323

Clean/Inspect 3324

Install 3324

Fuel Injector Repair 3325

Fuel Rail 3325

Remove for Lift Trucks Built Before January, 2010 3325

Remove for Lift Trucks Built After January, 2010 3327

Install for Lift Trucks Built Before January, 2010 3328

Install for Lift Trucks Built After January, 2010 3329

Fuel Injectors and Adapters 3329

Remove for Lift Trucks Built Before January, 2010 3329

Remove for Lift Trucks Built After January, 2010 3331

Clean 3332

Install for Lift Trucks Built Before January, 2010 3332

Install for Lift Trucks Built After January, 2010 3334

LPG Regulator Repair 3334

LPG Regulator 3334

Remove for Lift Trucks Built Before January, 2010 3334

Remove for Lift Trucks Built After January, 2010 3335

Install for Lift Trucks Built Before January, 2010 3337

Install for Lift Trucks Built After January, 2010 3337

LPG Regulator Fuel Filter 3338

Remove 3338

Install 3339

Lock-Off Solenoid and Cartridge 3339

Remove 3339

Install 3340

Control System 3340

Electronic Control Unit (ECU) and Injector Driver Modules Assembly 3340

Remove 3340

Install 3341

Electronic Control Unit (ECU) 3342

Remove 3342

Install 3342

Injector Driver Modules 3343

Remove 3343

Install 3343

Fuel Pressure Sensor 3344

Remove 3344

Install 3344

Low LPG Pressure Switch 3344

Remove 3344

Install 3345

LPG Pressure Sensor 3345

Remove 3345

Install 3346

Oxygen Sensor 3346

Exhaust System Repair 3347

GM 4 3L Engine for Lift Truck Model GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818) 3347

Remove for Lift Trucks Built Before January, 2010 3347

Remove for Lift Trucks Built After January, 2010 3349

Inspect 3351

Install for Lift Trucks Built Before January, 2010 3351

Install for Lift Trucks Built After January, 2010 3351

GM 4 3L Engine for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813) 3352

Remove for Lift Trucks Built Before January, 2010 3352

Remove for Lift Trucks Built After January, 2010 3354

Inspect 3357

Install for Lift Trucks Built Before January, 2010 3357

Install for Lift Trucks Built After January, 2010 3358

GM 4 3L Engine for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878) 3359

Remove for Lift Trucks Built Before January, 2010 3359

Remove for Lift Trucks Built After January, 2010 3362

Inspect 3363

Install for Lift Trucks Built Before January, 2010 3364

Install for Lift Trucks Built After January, 2010 3364

GM 4 3L Engine for Lift Truck Models GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879) 3365

Remove for Lift Trucks Built Before January, 2010 3365

Remove for Lift Trucks Built After January, 2010 3368

Inspect 3369

Install for Lift Trucks Built Before January, 2010 3370

Install for Lift Trucks Built After January, 2010 3370

Oxygen Sensor 3371

Remove 3371

Install 3372

LPG Fuel Testing 3372

General 3372

Available Fuel Tests 3372

Composition Test (ASTM D-2163) 3372

Ammonia Test (ASTM D-4490) 3373

Basic Nitrogen Test (ASTM UOP269-90) 3373

Residues Test (ASTM D-2158) 3373

Vapor Pressure Test (ASTM D-2598) 3373

Sulfur Compounds Test (ASTM D-5623) 3373

Methanol Test (ASTM D-4864) 3373

Copper Corrosion (ASTM D-1838) 3373

Where To Send LPG Fuel Samples For Testing 3373

524262276 0900YRM1244 (06 2012) US EN 3377

toc 3377

Gasoline Fuel System 3377

Safety Precautions Maintenance and Repair 3378

General 3381

Electronic Throttle Body Repair 3381

Electronic Throttle Body 3381

Remove 3381

Clean/Inspect 3381

Install 3382

Fuel System Repair 3383

Before Repair Procedure 3383

After Repair Procedure 3383

Fuel Leakage Check for Lift Trucks Built Before January, 2010 3383

Fuel Leakage Check for Lift Trucks Built After January, 2010 3384

Fuel Line Pressure Check 3386

Fuel Injector Repair 3387

Remove 3387

Install 3397

Control System 3398

Electronic Control Unit (ECU) 3398

Remove for Lift Trucks Built Before January, 2010 3398

Remove for Lift Trucks Built After January, 2010 3399

Install for Lift Trucks Built Before January, 2010 3400

Install for Lift Trucks Built After January, 2010 3401

Exhaust System Repair 3402

GM 4 3L Engine for Lift Truck Model GLC40, 45, 55VX; GLC55SVX; ( 3402

Remove for Lift Trucks Built Before January, 2010 3402

Remove for Lift Trucks Built After January, 2010 3404

Inspect 3404

Install for Lift Trucks Built Before January, 2010 3406

Install for Lift Trucks Built After January, 2010 3406

GM 4 3L Engine for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45 3407

Remove for Lift Trucks Built Before January, 2010 3407

Remove for Lift Trucks Built After January, 2010 3409

Inspect 3411

Install for Lift Trucks Built Before January, 2010 3411

Install for Lift Trucks Built After January, 2010 3412

GM 4 3L Engine for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (G 3413

Remove for Lift Trucks Built Before January, 2010 3413

Remove for Lift Trucks Built After January, 2010 3415

Inspect 3417

Install for Lift Trucks Built Before January, 2010 3417

Install for Lift Trucks Built After January, 2010 3418

GM 4 3L Engine for Lift Truck Models GLC/GDC60VX, GLC/GDC70VX (G 3418

Remove for Lift Trucks Built Before January, 2010 3418

Remove for Lift Trucks Built After January, 2010 3421

Inspect 3421

Install for Lift Trucks Built Before January, 2010 3423

Install for Lift Trucks Built After January, 2010 3423

Oxygen Sensor 3424

Remove 3424

Install 3424

524262279 1800YRM1247 (09 2018) US EN 3427

General 3431

Dry Brake System 3431

Wet Brake System 3432

Service Brakes Repair (Dry Brake) 3436

Remove and Disassemble 3436

Clean 3438

Inspect 3439

Assemble and Install 3439

Adjust 3443

Parking Brake Repair 3443

Dry Brake System 3444

Remove and Disassembly 3444

Assemble and Install 3446

Wet Brake System 3446

Remove and Install 3447

Assemble and Install 3453

Adjust 3453

Dry Brake System 3453

Wet Brake System 3454

Lift Trucks With a Pedal or Forward Reverse LeverFoot Directional Control 3454

Master Cylinder Repair 3455

Remove 3455

Disassemble 3460

Clean and Inspect 3461

Assemble 3462

Install and Adjust 3462

Accumulator 3464

Pre-Charge Check 3465

Remove 3466

Install 3468

Modulating Brake Valve, Accumulator Charge Valve, and Accumulator 3468

Remove 3469

Modulating Brake Valve 3470

Disassemble 3470

Clean and Inspect 3472

Assemble 3472

Accumulator Charge Valve 3473

Disassemble 3473

Clean and Inspect 3475

Assemble 3475

Install 3476

Pressure Checks 3477

Accumulator Charge Valve Check 3477

Accumulator Check 3477

Service Brakes Adjustment (Dry Brake) 3478

Service Brakes Adjustment 3478

Brake System Air Removal 3479

Using Pressure Bleed System 3479

Using Brake Pedal Pressure 3480

Lift Truck Models with Master Cylinder 3480

Lift Truck Models with Modulating Brake Valve 3480

Brake Pedal Adjustment 3481

For Lift Truck Models GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813), GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3481

For Lift Truck Model GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 3482

Free Pedal Adjustment 3484

Torque Specifications 3485

524265342 4000YRM1250 (09 2018) US EN 3489

Safety Procedures When Working Near Mast 3495

Fork Replacement 3497

Remove, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 3497

Remove, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 3499

Remove, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 3500

Install, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 3501

Install, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 3502

Install, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017 GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 3503

Checks, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 3503

Checks, Lift Truck Models Equipped With Fork Positioner and Manufactured After March, 2017GLC40, 45, 55VX, GLC55SVX (GC/GLC080, 100, 120VX, GC/GLC80, 100VXBCS, GC/GLC120SVX, GC/GLC120VXPRS (G818) and GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX (K813) 3505

Checks, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 3505

Fixed Carriage Replacement 3507

Remove, Carriage With Hook Forks 3507

Remove, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3516

Install, Carriage With Hook Forks 3517

Install, Carriage With Pin Type Forks Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3517

Disconnecting Attachment Hydraulic Quick Disconnect Hoses 3518

Connecting Attachment Hydraulic Quick Disconnect Hoses 3518

Integral Sideshift Carriage Repair 3519

Remove, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 3519

Disassemble 3519

Clean and Inspect 3522

Assemble 3522

Install, for lift truck models ERC35-55HG (ERC70-120HH) (C839), GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 3523

Hang On Sideshift Carriage Repair 3523

Remove, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 3523

Disassemble 3535

Clean and Inspect 3544

Assemble 3545

Install 3546

Bolzoni Hang-On Sideshift Carriage Repair 3548

Remove 3548

Disassemble Carriage 3550

Clean and Inspect 3553

Assemble 3553

Install 3556

Fork Positioner 3558

Two-Stage Mast With Limited Free-Lift Repair 3559

Remove 3559

Disassemble 3563

Clean and Inspect 3566

Assemble 3583

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3585

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and ERC35-55HG (ERC70-120HH) (C839) 3586

Header Hose Alignment 3598

Two-Stage Mast With Full Free-Lift Repair 3608

Remove 3608

Disassemble 3610

Clean and Inspect 3622

Assemble 3623

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) 3625

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818) and ERC35-55HG (ERC70-120HH) (C839) 3628

Header Hose Installation and Adjustment 3632

Installation 3632

Adjustment 3632

Three-Stage Mast With Full Free-Lift Repair 3633

Remove 3633

Disassemble 3635

Clean and Inspect 3665

Assemble 3666

Install, Lift Truck ModelsGLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813) and GLP/GDP60VX, GLP/GDP70VX, (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) 3670

Install, Lift Trucks ModelsGLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and ERC35-55HG (ERC70-120HH) (C839) 3675

Header Hose Alignment for GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818, G818), GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813, K813), and ERC35-55HG (ERC70-120HH) (C839) 3682

Header Hose Alignment for GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) and GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 3688

Mast Operation Check 3692

Tilt Cylinder Adjustment 3692

Lift Chains Adjustment 3693

Mast Adjustments 3694

Load Roller Adjustment 3694

Mast Side Kicking Adjustment 3696

Shimming The Mast Mounting Pin, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (F813, G813, H813, K813) 3697

Carriage Adjustments 3700

524288194 1300YRM1317 (03 2020) UK EN 3703

Transmission Repair 3707

Remove 3707

Torque Converter, Remove 3707

Disassemble 3708

Clean and Inspect 3757

Housings 3757

Oil Seals and Gaskets 3757

Bearings 3757

Gears and Shafts 3758

Assemble 3758

Torque Converter, Install 3799

Install 3800

Control Valve Repair 3801

Remove 3801

Disassemble 3801

Clean 3803

Inspect 3803

Assemble 3803

Install 3804

Torque Specification 3805

524288194 1300YRM1317 (03 2020) US EN 3807

Transmission Repair 3811

Remove 3811

Torque Converter, Remove 3811

Disassemble 3812

Clean and Inspect 3861

Housings 3861

Oil Seals and Gaskets 3861

Bearings 3861

Gears and Shafts 3862

Assemble 3862

Torque Converter, Install 3903

Install 3904

Control Valve Repair 3905

Remove 3905

Disassemble 3905

Clean 3907

Inspect 3907

Assemble 3907

Install 3908

Torque Specification 3909

524288212 8000YRM1320 (06 2019) US EN 3911

Lift Truck Lifting Capacity 3915

Counterweight Weights 3915

Tire Sizes 3915

Capacities 3916

Electrical System 3923

Transmission Oil Pressures 3924

Hydraulic System Relief Pressures 3928

Steering System 3929

Stall Speeds (in RPM ±100 rpm) 3930

GM 4 3L Gas GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879) 3930

GM 4 3L LPG GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879) 3930

GM 4 3L Gas GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878) 3930

GM 4 3L LPG GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878) 3930

Cummins 4 5L Diesel GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879) 3931

Cummins QSB 3 3L Diesel GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (D879) 3931

Cummins 4 5L Diesel GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878) 3931

Cummins QSB 3 3L Diesel GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (D878) 3931

Mast Speeds 3932

Tilt Angles 3933

Front End Equipment – Mast Creep 3934

Mast Creep 3934

Engine Specifications 3934

Torque Specifications 3936

Frame 3936

Mast, Lift Truck Models GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879) 3936

Mast, Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878) 3937

Hang On Sideshift Carriage With Fork Positioner, Lift Truck Models Manufactured After August, 2012GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (D878) 3937

Steering System 3937

Transmission 3938

Engine – GM 4 3L 3938

Engine – Cummins 4 5L and QSB 3 3L Diesel 3939

524288879 0100YRM1321 (11 2016) US EN 3941

General 3945

Description 3946

Side Covers, Seat, Dash, and Hood Replacement 3947

Side Covers 3947

Remove 3947

Install 3947

Seat and Seat Plate 3948

Remove Seat 3948

Remove Seat Plate 3948

Install Seat Plate 3948

Install Seat 3948

Operator Restraint System 3952

Emergency Locking Retractor (ELR) 3952

Seat Plate and Seat Rail Check 3952

Steering Column, Dash, Kick Panel, and Seal Plate 3952

Remove 3952

Install 3955

Hood Support and Door Assembly 3957

Remove 3957

Install 3957

Hood Door Assembly 3962

Remove 3962

Install 3962

Steering Column 3963

Description 3963

Steering Column Repair 3963

Remove 3963

Disassemble 3964

Clean 3967

Inspect 3967

Assemble 3967

Install 3967

LPG Tank and Bracket Assembly 3967

Counterweight Replacement 3968

Remove 3968

Install 3969

Tow Pin, Remove and Install 3971

Overhead Guard Replacement 3971

Remove 3971

Install 3973

Engine Replacement 3973

Remove Engine 3973

Remove Transmission 3998

Remove Engine and Transmission 4001

Install Engine 4004

Install Transmission 4008

Install Engine and Transmission 4009

Electronic Throttle Replacement 4012

Cummins 4 5L Diesel Engine With Electronic Throttle 4013

Remove 4013

Install 4013

Pull Actuator Linkage Adjustment 4018

Low Idle Adjustment 4018

Throttle Pedal and Cable Adjustment 4018

Cummins 4 5L Diesel Engine 4019

Exhaust System Repair 4020

GM 4 3L Engine for Lift Truck Models GLP60VX, GLP70VX (GP/GLP135VX, GP/GLP155VX) (C878, D878) 4021

GM 5 7L Engine for Lift Truck Model GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909) 4021

Cummins QSB 3 3L Engine for Lift Truck Models GDP60VX, GDP70VX (GDP135VX, GDP155VX) (C878, D878), GDP80VX, GDP80VX9, GDP90VX (GDP170VX, GDP175VX36, GDP190VX) (A909) 4021

Remove 4021

Inspect 4023

Install 4023

Cummins 4 5L Diesel Engine for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878) 4023

Remove 4023

Inspect 4025

Install 4025

Cooling System 4025

Description 4025

Hydraulic Filter Assembly Repair 4025

Remove 4026

Install 4026

Fuel and Hydraulic Tanks Repair 4028

Inspect 4028

Clean 4028

Steam Method of Cleaning 4028

Chemical Solution Method of Cleaning 4029

Additional Preparations for Repair 4029

Small Leaks, Repair 4030

Large Leaks, Repair 4030

Preparations for Use After Repair 4030

Safety Labels 4030

524288884 8000YRM1322 (12 2018) US EN 4039

General 4045

Serial Number Data 4045

How to Move Disabled Lift Truck 4046

How to Tow Lift Truck 4046

How to Put Lift Truck on Blocks 4047

How to Raise Drive Tires 4047

How to Raise Steering Tires 4047

How to Clean a Lift Truck 4048

Maintenance Schedule 4049

Maintenance Procedures Every 8 Hours or Daily 4070

How to Make Checks With Engine Stopped 4070

Tires and Wheels 4070

Safety Labels 4070

Mast, Carriage, Lift Chains, Header Hoses, Attachment 4071

Operator Restraint System 4071

Emergency Locking Retractor (ELR) 4071

Adjust Seat – Full Suspension 4072

Adjust Seat – Internal Suspension 4074

Seat Plate and Seat Rails 4074

Engine Compartment 4074

Paper Application 4074

Fuel, Oil, and Coolant Leaks, Check 4075

Hydraulic Hoses 4075

Coolant Hoses 4075

Steering Column Gas Cylinder 4075

Transmission 4075

Hydraulic System Oil 4076

Engine Oil 4077

Air Filter 4083

Forks 4083

Remove 4083

Inspect 4083

Install 4084

Adjust 4084

Hang On Sideshift Carriage 4084

How to Make Checks With Engine Running 4086

Indicator Lights, Horn, Fuses, and Relays 4086

Service Brakes 4089

Brake Oil Level 4089

Operation, Check 4089

Parking Brake 4089

Engine Oil Pressure 4090

Cooling System 4090

Steering System 4091

Control Levers and Pedals 4091

Lift System, Operate 4091

Air Filter 4092

Fuel/Water Separator Filter, Cummins 4 5L and QSB 3 3L Diesel Engine 4092

First Service After First 100 Hours of Operation 4092

GM 4 3L Engine Oil and Oil Filter 4092

Cummins 4 5L and QSB 3 3L Engine Oil and Oil Filter 4093

Maintenance Procedures Every 250 Hours or 6 Months 4094

GM 4 3L Engine Oil and Oil Filter Change 4094

Drive Belt 4094

GM 4 3L Engine 4094

Fan and Alternator Drive Belt 4094

Drain Tar From LPG Regulator 4095

Drain Tar From LPG Converter 4096

Cleaning Carbon Buildup From Intake Valves – GM 4 3L LPG Engine 4097

Maintenance Procedures Every 500 Hours or 6 Months 4098

Hydraulic System Oil 4099

Hydraulic Tank Breather 4102

Inspect 4102

Battery 4102

Cummins 4 5L and QSB 3 3L Engine Oil and Oil Filter 4102

Fuel/Water Separator Filter Replacement, Cummins 4 5L and QSB 3 3L Engine 4103

Remove 4103

Install 4103

Final Fuel Filter Replacement (Cummins QSB 3 3L Engine) 4105

Priming the Fuel System (Cummins 4 5L and QSB 3 3L Engine) 4106

Controlled Venting 4106

Manual Bleeding 4106

Low Idle Speed Adjustment, Cummins 4 5L Engine Only 4106

Drive Belt 4107

Cummins 4 5L and QSB 3 3L Diesel Engine 4107

Fan and Alternator Drive Belt 4107

Clean Debris From Radiator Core 4108

Transmission Oil, Breather, and Wet Brake Axle Oil Level Check 4108

Wet Brake Center Body Oil Level Check 4109

Forks 4111

Mast Lubrication 4112

Header Hose Checks 4116

Lift Chain Lubrication 4116

Tilt Cylinder Lubrication 4116

Master Brake Cylinder Rod End Pin Lubrication 4118

Manual Hydraulic Levers Lubrication 4118

Brake Oil 4118

Tie Rod Lubrication 4119

Parking Brake Adjustment 4120

Maintenance Procedures Every 1000 Hours or 6 Months 4121

Valve Clearance, Check and Adjust 4121

Ignition System 4121

GM 4 3L Engine 4121

LPG Fuel Filter Element Replace, GM 4 3L Engine 4121

Remove 4121

Install 4122

In-Line Filter Replacement, Cummins 4 5L Engine 4122

Remove 4122

Install 4123

Lift Chains Wear Check 4124

Lift Chain Lubrication 4124

Hang On Sideshift Carriage, Check Sliding Surfaces 4125

Steering Axle Spindle Bearings 4128

Control Levers and Pedals 4129

Inspect Engine Electrical System, Connectors 4129

Transmission Oil, Filter, Breather Change and Wet Brake Drive Axle Oil Change 4130

Parking Brake Lever Lubrication, Wet Brake Axle 4134

Normal Operating Environment 4134

Heavy Duty or Contaminated Environment 4135

Remove 4135

Clean and Inspect 4136

Install 4136

Maintenance Procedures Every 2000 Hours or Annually 4137

Hydraulic System 4137

Hydraulic Filter Assembly, Replace 4137

Install 4138

Hydraulic Tank Breather, Replace 4139

Ignition System: Distributor Cap, Rotor, and Spark Plug Wires 4141

Cooling System Check 4141

Air Filter 4143

Oxygen Sensor, GM 4 3L Engine Equipped With GFI Installed 4144

LPG Regulator Fuel Filter, GM 4 3L Engines with GFI Installed 4145

Remove 4145

Install 4146

Gasoline Fuel Filter 4146

Remove and Replace 4146

LPG Fuel Injector, GM 4 3L Engines with GFI Installed 4147

Gasoline Fuel Injector, GM Engines 4147

Fuel Injector, Cummins 4 5L and QSB 3 3L Engine 4147

Forks 4147

Brake Oil (Master Cylinder), Change 4147

Test Regulator PressureLPG/GAS 4148

Check Throttle Shaft for Sticking 4148

Inspect Exhaust Manifold and Piping for Leaks 4148

Transmission Automatic Clutch Calibration 4148

Brake System Accumulator 4148

Valve Clearance, Check and Adjust for Cummins QSB 3 3L Diesel Engine 4148

Wheel Bearings 4149

Steer Wheels, Lubrication 4149

Maintenance Procedures Every 4000 Hours or 2 Years 4149

Hydraulic Oil, Replace 4150

Valve Clearance, Check and Adjust for Cummins 4 5L Diesel Engine 4152

Safety Procedures When Working Near Mast 4154

Fuel Filter Water Removal 4157

Lift Chain Adjustments 4157

Jump-Starting the Lift Truck 4159

Jump-Starting Using a Battery Charger 4159

Jump-Starting a Lift Truck Using Another Lift Truck 4159

Welding Repairs 4160

Overhead Guard Changes 4160

Wheel and Tire Replacement 4160

General 4160

Pneumatic Tire With Tube, Repair 4160

Remove Wheels From Lift Truck 4160

Remove Tire From Wheel 4161

Install Wheel in Tire 4164

Install Tire on Two-Piece Wheel 4166

Add Air to Pneumatic Tires With Tube 4167

Install the Wheels 4167

Dual Drive Wheels, Install 4168

Pneumatic Tubeless Tire, Repair 4169

Remove Wheels From Lift Truck 4169

Add Air to Pneumatic Tubeless Tire 4174

Wheels, Install 4174

Solid Rubber Tires on Pneumatic Wheels, Change 4174

Adhesives and Sealants 4178

524294878 2100YRM1328 (09 2018) US EN 4181

General 4185

Safety Procedures When Working Near Mast 4185

Tilt Cylinder Repair 4187

Remove 4187

Disassemble 4192

Clean 4194

Inspect 4194

Assemble 4194

Install 4196

Tilt Cylinders, Adjust 4198

Tilt Cylinder Leak Check 4199

Lift Cylinder Repair 4200

Remove 4200

Disassemble 4210

Clean 4213

Inspect 4213

Assemble, Lift Truck Models and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878)GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 4213

Assemble, Lift Truck Models GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 4213

Install, Lift Truck Models and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878)GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 4214

Install, Lift Truck Models GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 4214

Free-Lift Cylinder Repair 4215

Remove 4215

Disassemble 4221

Clean 4223

Inspect 4223

Assemble, Lift Truck Models and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878)GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 4224

Assemble, Lift Truck Models GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 4224

Install, Lift Truck Models and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878)GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) 4224

Install, Lift Truck Models GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 4225

Sideshift Cylinder Repair 4226

Remove 4226

Disassemble 4227

Clean 4230

Inspect 4230

Assemble 4231

Install 4232

Bolzoni Sideshift Cylinder Repair 4233