$41.95

Yale Forklift E875 GLPGDPGTP( 40N, 50N, 60N, 70N) Service Manual PDF

Yale Forklift E875 (GLPGDPGTP40N, GLPGDPGTP50N, GLPGDPGTP60N, GLPGDPGTP70N) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift E875 (GLPGDPGTP40N, GLPGDPGTP50N, GLPGDPGTP60N, GLPGDPGTP70N) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1622

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift E875 (GLPGDPGTP40N, GLPGDPGTP50N, GLPGDPGTP60N, GLPGDPGTP70N) Service Manual – PDF DOWNLOAD

524150797 8000YRM0231 (02 2023) US EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

550232091 0100YRM2298 (07 2023) US EN 23

Introduction 31

General 31

Overhead guard and cab repair 32

Overhead guard repair 32

Remove 32

Install 36

Cab components repair 37

Steel Doors 37

Remove 38

Install (Existing) 39

Install (New) 39

PVC Doors 41

Remove 42

Install 45

Screens 46

Front Screen and Wiper 46

Remove 46

Install 49

Top Screen and Wiper 51

Top Screen Remove 52

Top Screen Install 53

Top Wiper Remove 54

Top Wiper Install 56

Rear Screen and Wiper 57

Remove 58

Install 61

Washer Fluid Tank and Supply Lines 62

Remove (Washer Fluid Tank) 63

Install (Washer Fluid Tank) 64

Remove (Supply Lines) 64

Install (Supply Lines) 64

Operator Fan 65

Remove 65

Install 65

Front Grab Handle 65

Remove 65

Install 66

Rear Drive Handle with Horn Button 66

Remove 66

Install 66

12 Volt Power Supply with 2 USB Charging Ports 67

Remove (12 Volt Power Supply) 67

Install (12 Volt Power Supply) 67

Remove (USB Charging Ports) 67

Install (USB Charging Ports) 68

Dome Light 68

Remove 68

Install 68

Noise abatement (sound liners) 69

Hood liners 69

Remove 69

Install 69

Overhead guard liners 69

Remove 69

Install 69

Dash panel liners 70

Remove 70

Install 70

Heater and air conditioner repair 71

Heater repair 71

Heater 72

Remove 72

Install 73

Air conditioner repair 73

Air Conditioning 73

Safety Precautions 74

General Statements for Repairs 74

Residual Pressure 74

Refrigeration Circuit 74

Air Conditioner (A/C) Repair 74

Remove Condenser 76

Install Condenser 77

Remove A/C Compressor 78

Install A/C Compressor 78

Remove Tubes and Expansion Block Valve 79

Install Tubes and Expansion Block Valve 80

Operator station repair 81

Seat repair-Full Suspension 81

Remove 81

Disassemble 82

Armrests 82

Seats 82

Suspension (Seat pan) 84

Assemble 84

Suspension (Seat pan) 84

Seats 84

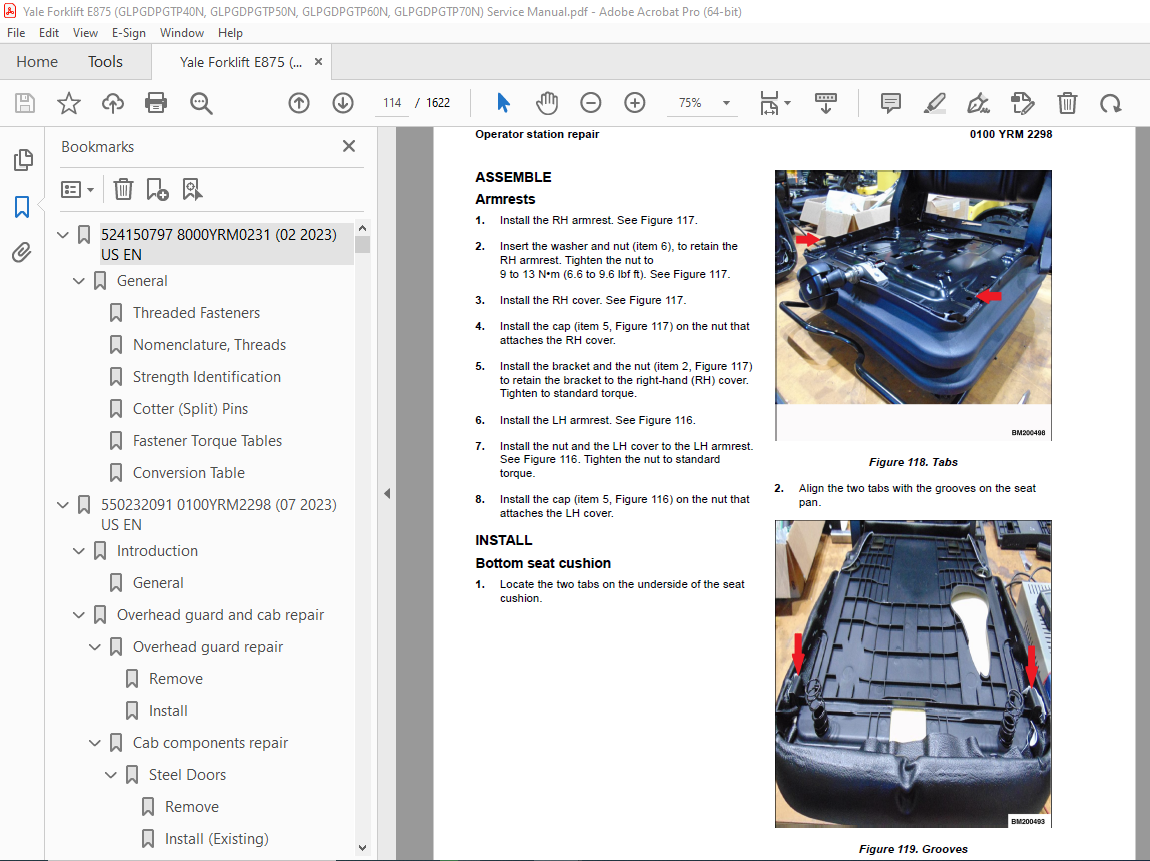

Armrests 85

Install 86

Seat repair-Non suspension seat 86

Remove 86

Disassemble 87

Operator Presence Sensor 87

Armrests 88

Seat rails 88

Assemble 88

Seat rails 88

Armrests 89

Operator Presence Sensor 89

Install 89

Seat repair-Air suspension 90

Remove 90

Disassemble 91

Armrests 91

Seat cushions 91

Backrest 93

Level adjustment handle 94

Bellows 95

Suspension (Seat pan) 97

Storage box 97

Backrest adjustment 98

Seat switch cable harness 99

Shock absorber 101

Seat plate 101

Static belt 102

Compressor 103

Air spring 104

Swinging structure 105

Assemble 106

Swinging structure 106

Air spring 106

Compressor 106

Seat plate 106

Static belt 106

Shock absorber 107

Seat switch cable harness 107

Backrest adjustment 107

Handles 108

Storage box 108

Bellows 108

Suspension (Seat pan) 108

Backrest 108

Seat cushions 108

Armrests 110

Install 110

Seat repair-value vinyl 111

Remove 111

Bottom seat cushion 112

Disassemble 113

Armrests 113

Assemble 114

Armrests 114

Install 114

Bottom seat cushion 114

Operator restraint system repair 116

Description 116

Seat belt-operational checkout 116

Emergency Locking Retractor (ELR) 116

Remove 116

Install 117

Pedals and linkage repair 117

Brake pedal 117

Remove 117

Install 120

Adjust 121

Throttle pedal (manual) 121

Remove 121

Install 123

Throttle pedal (electronic) 123

Remove 123

Install 124

Foot Directional Control pedal 125

Remove 125

Install 126

Dual pedal 126

Remove 126

Install 127

Park brake 127

Lift trucks with a with a Monotrol®Foot Directional Control pedal: 127

Adjust 127

Releasing the cable adjustment 128

Remove 128

Install 129

Accessories and options 131

Accessory options 131

Monitor holder 131

Tablet holder 131

Phone holder 131

Cup holder 132

Scanner holder 132

Tape dispenser 133

Stretch film roller 133

Accessory bar-fixed 133

Remove 133

Install 134

Accessory bar-swing out (rectangle OHG) 134

Remove 134

Install 135

Accessory bar-swing out (figure 8 OHG) 135

Remove 135

Install 135

Operator fan 136

Remove 136

Install 136

Sun shade 137

Remove 137

Install 137

550232092 0600YRM2299 (05 2023) US EN 139

Introduction 149

General 149

Engine identification 149

Major engine component identification 149

Location of labels 151

Diesel engine labels 151

LPG engine 152

Diesel engine repair 154

Diesel engine specifications 154

Cylinder head specifications 154

Camshaft and timing gear train specifications 156

Crankshaft and piston specifications 157

Cylinder block specifications 159

Special torque chart 160

Diesel cylinder head repair 162

Disassembly of Cylinder Head 162

Remove 168

Glow plugs 168

Valve cover 168

Rocker arm assembly 168

Cylinder head 169

Intake and exhaust valves 170

Valve guides 171

Clean and Inspect 171

Cylinder head components 172

Push rods 172

Push rod bend 172

Rocker arm assembly 172

Rocker arm shaft hole diameter 172

Valve guides 173

Cylinder head 173

Cylinder head distortion 173

Intake and exhaust valves 173

Valve stem diameter 173

Valve stem straightness 173

Valve recession 174

Valve face and valve seat 174

Valve springs 175

Assemble and Install 175

Valve Guides 175

Valves and valve springs 176

Cylinder head 177

Rocker arm assembly 177

Glow plugs 178

Valve cover 178

Engine assembly 178

Diesel timing gear case repair 179

Timing gear case cover 179

Remove 179

Inspect 180

Install 181

Timing gear case 181

Checks 181

Check timing gear backlash 181

Measuring idler gear-to-crankshaft gear backlash 181

Measuring idler gear-to-camshaft gear backlash 182

Remove 182

Install 184

Diesel camshaft and cylinder block repair 187

Remove engine components 188

Disassemble 188

Pistons and connecting rods 188

Remove 190

Crankshaft 190

Inspect 193

Crankshaft oil seals 193

Cylinder Block 194

Honing and Boring 196

Pistons 197

Connecting Rod 199

Tappets 199

Crankshaft 200

Camshaft 201

Camshaft bushing and bores 202

Idler gear and shaft 202

Assemble 203

Camshaft 203

Crankshaft 203

Pistons and Connecting Rods 205

Install 207

Diesel lubrication system repair 208

Check engine lubricating oil pressure 209

Remove 209

Oil pump components 209

Clean and inspect 211

Outer rotor outside clearance 211

Outer rotor to inner rotor tip clearance 211

Outer rotor side clearance 212

Rotor shaft clearance 212

Install 212

Oil pump service information 213

Diesel fuel system repair 214

Fuel system components 214

Remove 214

Injector 214

Common rail 216

Supply pump 217

Install 218

Supply pump 218

Common rail 218

Injector 219

Diesel flywheel repair 220

Remove 220

Install 220

Diesel electrical system repair 221

Starter 221

Remove 221

Disassemble 222

Install 222

Alternator 224

Remove 224

Install 224

Engine Control Unit 225

Remove 225

Install 225

Diesel exhaust and after treatment repair 226

Diesel Particulate Filter (DPF) System 226

Remove 226

DPF assembly 226

Soot filter 228

Inspect 229

Install 230

Soot filter 230

DPF assembly 231

Exhaust Gas Recirculation (EGR) system 232

EGR system configuration 232

Disassemble 232

EGR cooler 232

EGR valve and lead valve 233

Clean 234

EGR cooler 234

EGR pipe and other connecting elbows 234

EGR lead valve 234

Install 235

EGR valve and lead valve 235

EGR Cooler 235

Intake throttle 236

Precautions for handling the intake throttle 236

Exhaust throttle 236

Diesel engine checks, adjustments, and calibrations 237

Valve Clearance Adjustments 237

Alternator checks 238

Test stater coil continuity 238

Test stater coil short to ground 238

Test alternator regulated output 238

Exhaust and aftertreatment 239

EGR valve (check, clean, and test) 239

EGR active control 239

Precautions for cleaning 240

Cleaning the EGR valve 240

Exit the EGR active control 240

Intake throttle 240

Special tools for diesel engines 241

LPG engine repair 245

LPG engine specifications 245

Cylinder head specifications 245

Camshaft and timing gear train specifications 247

Crankshaft and piston specifications 248

Cylinder block specifications 250

Fuel specifications 250

Oil pump service information 251

Special torque chart 253

LPG cylinder head repair 255

Disassemble cylinder head 256

Remove 260

Valve cover 260

Rocker arm 260

Dissassemble rocker arm 260

Cylinder head 261

Intake and exhaust valves 262

Valve guides 262

Clean and Inspect 263

Cylinder head components 263

Push rods 263

Push rod bend 264

Rocker arm assembly 264

Rocker arm shaft hole diameter 264

Valve guides 264

Cylinder head 265

Cylinder head distortion 265

Intake and exhuast valves 265

Valve stem diameter 265

Valve stem straightness 265

Valve recession 265

Valve face and valve seat 266

Valve springs 267

Assemble 267

Valve guides 267

Valves and valve springs 268

Cylinder head 269

Rocker arm assembly 270

Install 271

LPG timing gear case repair 273

Remove 273

Timing gear case cover 273

Timing gear case 274

Idler shaft gear 274

Camshaft and camshaft gear 274

Timing gear case 276

Inspect 276

Install 276

LPG camshaft and cylinder block repair 278

Remove the engine components 279

Disassemble 279

Pistons and connecting rods 279

Remove 281

Crankshaft 281

Inspect 284

Crankshaft oil seals 284

Cylinder block 285

Honing and Boring 285

Pistons 286

Connecting Rod 288

Tappets 288

Crankshaft 289

Camshaft 290

Camshaft bushing and bores 291

Idler gear and shaft 291

Assemble 292

Pistons and Connecting Rods 292

Install 294

Crankshaft 294

Pistons 295

Install the engine components 296

LPG lubrication system repair 297

Check engine lubricating oil pressure 297

Remove 298

Oil pan 298

Oil pump 299

Clean and inspect 299

Outer rotor outside clearance 299

Outer rotor to inner rotor tip clearance 299

Outer rotor side clearance 300

Rotor shaft clearance 300

Assemble 301

Install 301

Oil pump 301

Oil pan 301

Oil pump service information 301

LPG fuel system repair 302

Fuel system components 302

Remove 302

Install 304

LPG flywheel repair 304

Remove 304

Inspect 305

Install 305

LPG electrical system repair 306

Starter 306

Remove 306

Install 306

Alternator 307

Remove 307

Install 307

Engine Control Unit 308

Remove 308

Install 308

LPG exhaust and aftertreatment repair 309

Remove 309

Inspect 311

Install 312

LPG engine checks, adjustments, and calibrations 313

Timing gear checks 313

Check timing gear backlash 313

Measuring idler gear-to-crankshaft gear backlash 313

Measuring idler gear-to-camshaft gear backlash 313

Valve Clearance Adjustments 314

Special tools for LPG engines 316

Bi-fuel engine repair 320

Bi-fuel engine specs 320

Bi-fuel cylinder head repair 320

Bi-fuel timing gear case repair 320

Bi-fuel camshaft and cylinder block repair 320

Bi-fuel lubrication system repair 320

Bi-fuel fuel system repair 320

Bi-fuel flywheel repair 320

Bi-fuel electrical system repair 320

Bi-fuel exhaust and aftertreatment repair 320

Bi-fuel engine checks, adjustments, and calibrations 320

Special tools for bi-fuel engines 320

550232093 0700YRM2300 (05 2023) US EN 323

Introduction 329

General 329

Cooling system repair 330

Fan repair 330

Remove 330

Inspect 332

Install 332

Fan repair (with hydraulic fan drive) 333

Remove 333

Inspect 337

Install 338

Water pump repair 339

Remove 339

Disassemble 342

Install 342

Radiator repair 343

Remove 343

Install 347

Radiator repair (with hydraulic fan drive) 348

Remove 348

Install 351

Cooling system flushing 352

Cooling system checks, adjustments, and calibrations 355

Hose check 355

Flow restriction check 355

Check for water flow restrictions in the radiator 355

Exhaust leak check 355

Thermostat and cooling system sensors check 355

Inspect 355

Temperature switch 355

Water temperature sensor 356

Thermostat 357

Radiator cap 357

550232095 1900YRM2302 (09 2023) US EN 359

Introduction 369

General 369

Hydraulic system repair 370

Hydraulic pump repair 370

Remove 370

Disassemble 376

Variable Displacement Pump 376

Hydraulic Gear Pump 378

Clean 380

Inspect 380

Assemble 380

Variable Displacement Pump 380

Hydraulic Gear Pump 380

Install 380

Variable Displacement Pump Checks and Adjustments 381

Pump Margin Pressure 381

Hydraulic control valve repair 382

Manual Control Valve 382

Remove 382

Disassemble 385

Clean and Inspect 385

Assemble 386

Install 386

Inlet Valve Section 386

Disassemble 386

Clean 387

Inspect 387

Assemble 387

Fan Drive Control Valve Section 388

Disassemble 388

Clean 389

Inspect 389

Assemble 389

Lift Control Valve Section 389

Disassemble 389

Clean 390

Inspect 390

Assemble 391

Tilt/Auxiliary Control Valve Sections 391

Disassemble 391

Clean 393

Inspect 393

Assemble 394

Outlet Valve Section 394

Disassemble 394

Clean 394

Inspect 395

Assemble 395

Accumulator 395

Remove 395

Install 396

Electronic Control Valve 396

Remove 396

Disassemble 398

Clean and Inspect 399

Assemble 399

Install 399

Inlet Valve Section 399

Disassemble 399

Clean 400

Inspect 400

Assemble 401

Fan Drive Control Valve Section 401

Disassemble 401

Clean 402

Inspect 402

Assemble 403

Lift Control Valve Section 403

Disassemble 403

Clean 404

Inspect 404

Assemble 405

Tilt/Auxiliary Control Valve Sections 405

Disassemble 405

Clean 406

Inspect 406

Assemble 407

Outlet Valve Section 407

Disassemble 407

Clean 407

Inspect 408

Assemble 408

Pressure Relief Valve Check and Adjustment 408

Primary Relief Valve 408

Secondary Relief Valve 409

Hydraulic supply and return repair 410

Hydraulic Supply and Return Hoses 410

Remove 410

Install 413

Mast Hoses 414

Remove 414

Install 418

Hydraulic Tank 418

Inspect 418

Clean 419

Steam Method of Cleaning 419

Chemical Solution Method of Cleaning 419

Additional Preparations for Repair 420

Small Leaks, Repair 420

Large Leaks, Repair 420

Preparations for use After Repair 420

Hydraulic oil cooler 420

Hydraulic Oil Cooler 420

Remove 420

Disassemble 421

Assemble 423

Install 423

Hydraulic calibrations 423

E-Hydraulic controls options 424

Calibration procedures 425

Service password entry 425

Hydraulic valve calibration warmup 426

Lift valve threshold 426

Lower valve threshold 426

Tilt valve threshold (Forward) 427

Tilt valve threshold (Back) 427

Auxiliary 1 Direction A valve output threshold 428

Auxiliary 1 Direction B valve output threshold 428

Auxiliary 2 Direction A valve output threshold 429

Auxiliary 2 Direction B valve output threshold 429

Steer system hydraulics repair 431

Steering pump repair 431

Remove 431

Disassemble 433

Clean 435

Inspect 435

Assemble 435

Install 435

Brake system hydraulics repair 436

Dry brake hydraulics repair 436

Wet brake hydraulics repair 436

Remove 436

Install 438

Cylinder repair 440

Tilt cylinder repair 440

Remove 440

Disassemble 441

Clean 442

Inspect 442

Assemble 443

Install 444

Tilt Cylinders, Adjust 444

Tilt Cylinders With Tilt Limit Spacers 444

Tilt Cylinders Without Tilt Limit Spacers 445

Tilt Cylinder Leak Check 446

Lift cylinder repair 446

Two-Stage Limited-Free-Lift (LFL) 446

Remove 446

Disassemble 447

Clean 448

Inspect 449

Assemble 449

Install 449

Two-Stage Full-Free-Lift (FFL) 450

Remove 450

Disassemble 451

Left-Hand Cylinder 451

Right-Hand Cylinder 452

Clean 453

Inspect 453

Assemble 454

Left-Hand Cylinder 454

Right-Hand Cylinder 455

Install 455

System Air Bleed Procedure 455

Three-Stage Full-Free-Lift (FFL) 456

Remove 456

Disassemble 457

Clean 458

Inspect 458

Assemble 459

Install 460

Four-Stage Full-Free-Lift (FFL) 460

Remove 460

Disassemble 461

Left-Hand main lift cylinder 461

Right-Hand main lift cylinder 462

Clean 463

Inspect 463

Assemble 464

Install 465

Free-Lift cylinder 465

Remove 465

Disassemble 466

Clean 467

Inspect 467

Assemble 468

Install 469

Seal Kit Installation 469

External Installation (Seal and Backup Ring) 469

Internal Installation (Piston Rod Assembly) 470

Lift cylinder leak check 470

Integral sideshift cylinder repair 470

General 470

Remove 470

Clean 472

Inspect 472

Assemble 472

Install 473

Integral Side-Shift Cylinder Gland Leak Checks 473

Hydraulics cleanliness 474

Flushing hydraulics after repair 474

Hydraulic System Flushing Techniques 474

Double Oil and Filter Change 474

Mechanical Cleaning 474

Cleaning of Components 474

Fluid conditioning and system flushing 475

Operation of the Filter Caddy 475

Filter Caddy operation 475

Fluid Conditioning Procedure 476

Filter Caddy Start-Up 476

System Flushing Procedure 477

Component Cleaning Procedure 477

Reservoir Cleaning Procedure 477

Cylinder Cleaning Procedure 477

Hose and Tube Cleaning Procedure 478

Valve Cleaning Procedure 478

Front-End Attachment Cleaning Procedure 479

System Flushing Procedure 479

Filter Caddy Start-Up 480

System Start-Up and Flushing 480

Reservoir Fluid Cleaning Times 481

Dealing With Different Fluid Types 481

Cleaning Procedure After Switching Fluids (Cross Contamination Flushing) 481

Filter Caddy Maintenance 482

Servicing the Strainer 482

DC Motor 482

Hydraulic oil sampling 482

Hydraulic Oil Sampling Method 482

Objective 482

General Guidelines 482

Synopsis 483

Hydraulic Oil Analysis Report Guidelines 484

Sampling Conditions 485

Equipment 485

Sampling Procedure 485

Hydraulic Oil Sampling 485

Sample Labeling 486

Results Documentation 486

550232096 4000YRM2303 (06 2023) US EN 489

Introduction 497

General 497

Safety Procedures When Working Near Mast 497

Fork and carriage repair 499

Fork removal and replacement 499

Integral Sideshift Carriage 499

Remove 499

Install 500

Checks 500

Carriage repair, 2-stage limited free lift 502

Standard Carriage 502

Remove 502

Clean and Inspect 503

Install 504

Integral Sideshift Carriage 505

Remove 505

Disassemble 508

Clean and Inspect 508

Assemble 509

Install 509

Auxiliary extension tubes (standard carriage) 510

Remove 510

Install 510

Auxiliary extension tubes (ISS carriage) 510

Remove 510

Install 510

Carriage repair, 2-stage full free lift 511

Standard Carriage 511

Remove 511

Clean and Inspect 512

Install 512

Integral Sideshift Carriage 513

Remove 513

Disassemble 516

Clean and Inspect 516

Assemble 517

Install 517

Auxiliary extension tubes (standard carriage) 518

Remove 518

Install 518

Auxiliary Extension Tubes (ISS Carriage) 518

Remove 518

Install 518

Carriage repair, 3-stage full free lift 519

Standard Carriage 519

Remove 519

Clean and Inspect 520

Install 520

Integral Sideshift Carriage 521

Remove 521

Disassemble 523

Clean and Inspect 524

Assemble 525

Install 525

Auxiliary extension tubes (standard carriage) 526

Remove 526

Install 526

Auxiliary extension tubes (ISS carriage) 526

Remove 526

Install 526

Carriage repair, 4-Stage Full Free Lift 527

Standard Carriage 527

Remove 527

Clean and Inspect 528

Install 529

Integral Sideshift Carriage 529

Remove 529

Disassemble 532

Clean and Inspect 532

Assemble 532

Install 533

Auxiliary Extension Tubes (Standard Carriage) 534

Remove 534

Install 534

Auxiliary Extension Tubes (ISS Carriage) 534

Remove 534

Install 535

Fork positioner 535

Mast repair 536

2-stage limited free lift (LFL) mast repair 536

Repair mast with serial number G507/G562 536

Remove 536

Disassemble 539

Clean and Inspect 544

Assemble 546

Install 547

2-stage full free lift (FFL) mast repair 549

Repair mast with serial number F509/F564 549

Remove 549

Disassemble 552

Clean and Inspect 554

Assemble 557

Install 558

3-stage full free lift (FFL) mast repair 559

Repair mast with serial number G508/G563 559

Remove 559

Disassemble 562

Clean and Inspect 566

Assemble 568

Install 569

4-Stage full free lift (FFL) Mast Repair 571

Repair Mast With Serial Number E515/B954 571

Remove 571

Disassemble 574

Clean and Inspect 580

Assemble 583

Install 584

Header Hose Repair 587

Header Hoses, 2-stage limited free lift (LFL) 587

Remove 587

Installation 587

Adjustment 589

Header Hoses, 2-stage full free lift (FFL) 589

Remove 589

Installation 590

Adjustment 594

Header Hoses, 3-stage full free lift (FFL) 595

Remove 595

Installation 595

Adjustment 599

Header Hose, 4-Stage Full Free Lift (FFL) 600

Remove 600

Install 601

Header Hose Tension Measurement Instructions 610

Adjustment 612

Adjustment Procedures 613

Carriage Adjustments 613

Lift Chains Adjustment 613

Lift Chains 613

Lift Trucks Equipped with Forks 614

Lift Trucks Equipped with Hook-Type Carriage and Attachment Without Forks 614

Mast Adjustments 614

Mast 614

Load Roller, Adjust 614

Mast Side Kicking, Adjust 617

Bolzoni attachment installation 618

Paper roll clamp installation 618

Bale clamp installation 618

Rotator installation 618

550232097 2200YRM2304 (07 2023) US EN 621

Introduction 635

General 635

Electrical system repair 636

Wire harness repair 636

Molex MX150 Series Connectors 636

MX150 Locations 641

Molex MX150 Series Terminals 641

Inspecting Wiring Terminals and Connectors 641

Removing Terminated Wires from Plug Connector 642

Removing Terminated Wires from Receptacle Connector 643

Installing Terminated Wires into Plug or Receptacle Connector 644

Wire Terminals 644

Unused Cavity Circuit Plug 644

Stripping Wire for Molex MX150 Series Terminals 644

Poor Wire Stripping Examples 645

Crimping Molex MX150 Series Terminals 646

Sensors, relays, and other electrical components repair 647

Sensors, Relays, and Other Electrical Components Repair 647

Accelerator Pedal Position Sensor 647

Remove 647

Install 648

Engine and Fuel Sensors and Switches, Yanmar Diesel Engine 648

Air Filter Restriction Switch 648

Remove 648

Install 648

Oil Pressure Sensor 648

Remove 648

Install 648

Engine Speed Sensor 648

Remove 648

Install 649

Engine Coolant Temperature (ECT) Sensor 649

Remove 649

Install 649

Throttle Position Sensor (TPS) 651

Remove 651

Install 652

Fuel/Water Separator Sensor 652

Remove 652

Install 652

Glow Plug Relay 653

Remove 653

Install 655

Engine Block Heater (2 1L Engine) 655

Remove 655

Install 655

Engine Block Heater (2 2L Engine) 656

Remove 656

Install 656

Exhaust Gas Sensors 656

Heated O2 Sensor 656

Remove 656

Install 657

Exhaust EGT Sensor 658

Remove 658

Install 658

Dynamic Stability System (DSS) 658

Mast Height Sensor (Discrete) 658

Remove 658

Install 659

Mast Height Sensor (Continuous) 659

Remove 659

Install 660

Mast Tilt Sensor 660

Remove 660

Install 661

Speed Sensor 661

Steer Axle Position Sensor 661

Remove 661

Install 662

Fuel Quality Sensor (FQS) – LPG/Dual Fuel Engines 662

Remove 662

Install 663

Synchronous Steering Column Sensor 663

Remove 663

Install 664

Service Brake Pedal Position Sensor – Single Pedal 664

Remove 664

Install 664

Brake Fluid Level Sensor 665

Remove 665

Install 665

Parking Brake Position Sensor 666

Remove 666

Install 666

Service Brake (Hydraulic) Pressure Transducer 666

Remove 666

Install 667

Service Brake (E-Brake) Position Sensor 667

Remove 667

Install 667

Monotrol Sensor 667

Remove 667

Install 668

Low Coolant Level Sensor 668

Remove 668

Install 669

Fuel Level Sensor, Gas and Diesel Engines Only 669

Remove 669

Install 669

Operator Presence Sensor 670

Remove 670

Install 670

Transmission Sensors 670

Speed Sensor 670

Remove 670

Install 671

Pressure Sensor 671

Remove 671

Install 671

Temperature Sensor 671

Remove 671

Install 671

Impact Sensor 671

Remove 671

Install 672

Load Weight Sensor 672

Remove 672

Install 672

Ambient Light Sensor 672

Remove 672

Install 674

Proximity Sensor 674

Remove 674

Install 674

Object Detection Sensors (Side) 675

Remove 675

Install 675

Object Detection Sensor (Rear) 675

Remove 675

Install 676

LPG Tank Interlock 676

Remove 676

Install 676

Smart Antenna 677

Remove 677

Install 677

Power distribution module (PDM) repair 677

Power Distribution Module 677

Remove 677

Install 678

Replacing PDM components (fuses and relays) 679

Battery service 682

Battery Remove and Install 682

Remove 682

Install 683

Battery Disconnect Switch (Optional) 683

Remove 684

Install 684

Light repair 684

Light Repair 684

LED Mast Lights 684

Remove 684

Install 685

LED Strobe Light 685

Remove 685

Install 685

Fork Laser Level Line 686

Remove 686

Install 686

Red or Blue Front Spot Light 686

Remove 686

Install 687

Red or Blue Rear Spot Light 687

Remove 687

Install 687

Front Work Lights 687

Remove 688

Install 688

Rear Work Light 688

Remove 688

Install 688

Rear Work Light with Red Line 689

Pedestrian Awareness Lights (PAL), Perimeter 689

Remove (Right Side) 689

Install (Right Side) 689

Remove (Rear) 689

Install (Rear) 690

Front LED Work Light with Marker Light 690

Remove 690

Install 691

Tail Light with Stop, Brake, Reverse, Hazard, and Turn Lights 691

Remove 691

Install 692

Controller removal and replacement 692

Controller Remove and Replace 692

VSM 692

Remove 692

Install 693

O-Box (E-Hydraulic) Controller 693

Remove 693

Install 694

Hydro Static Transmission (HST) controller 694

Remove 694

Install 695

I-Box (Accessory 1) 695

Remove 695

Install 695

I-Box (Accessory 2) 696

Remove 696

Install 696

Telemetry Wireless Asset Management System 696

Level 1 – Wireless Monitoring (WIFI Group) 696

Remove Telemetry Module 697

Install Telemetry Module 699

Remove Antenna 699

Install Antenna 700

Level 2 – Wireless Access 700

Telemetry Module 701

Antenna 701

RF-ID Reader 701

Remove 702

Install 702

Level 3 – Wireless Verification 702

Telemetry Module 703

Antenna 703

RF-ID Reader 703

Display Panel (Checklist) 703

Software 705

Loading and updating VSM software and truck Configuration Data Files (CDF)s with HYG Field Prog software 705

Installing the Field Prog software 705

Minimum system requirements 705

Open the Field Prog Tool 706

Using the Field Prog tool 707

Error behavior 711

CAN-based operations 712

Display programming 712

Programming the Display via USB 713

Setup 714

Run the Field Prog tool 714

Language 714

Loading and updating display and application software 715

Loading and Updating Display and Application Software 715

Minimum System Requirements 715

Configure Communications Settings 717

Installing Axcess Software 719

Using the Axcess Software 720

Programming the VSM 721

Begin Programming 722

Programming the Display via USB 722

Setup 723

Run the Tool 723

Transfer 724

Programming other controllers 724

Transmission Valve Calibration 725

Language 726

User interface (display) 726

User interface display 726

Navigation Key 726

Startup sequence 727

Side View Operator Screens 731

Switched Inputs and Preset Heights 732

Home screen 734

Loggin in 736

Log In or Out 736

Main Menu 737

View the Fault List 737

Fault List 737

Fault Filter 738

View hardware and software versions 739

Calibrations 739

Alarms 740

Diagnostics 741

Settings 744

Hydraulics 744

H1 Lift/Lower 744

H2 Tilt 745

H3 Third Hyd Function 745

H4 Fourth Hyd Function 745

H5 Fifth Hyd Function 745

H8 Pump 745

Drive 745

D1 Engine 745

D8 Traction 745

Sensors/Presets 745

Impact 746

Mast presets 746

Telemetry 746

Operators 746

Password Enabled 746

Add New 746

Existing User 746

Maintenance 747

M 1 Reminder 747

M 2 Checklist 747

Truck Setup 747

T1 Display 747

T2 Lights 747

T3 Time Out 747

T4 Alarms 747

T5 Alarms 748

T6 Inputs 748

Powertrain Protection System with Engine Shutdown 748

Powertrain Empty Seat Engine Shutdown 748

Display Icons 749

Service Display Menu Structure 771

Calibrations 796

Transmission warm-up 796

Hydraulic valve calibration warm-up 796

Calibrations 796

DSS calibrations 796

Return To Set Tilt Calibration 796

Synchronous Steering Calibration 797

Lift valve calibration 799

Lift valve threshold calibration 799

Lower valve calibration 801

Lower valve threshold calibration 801

Tilt back valve calibration 802

Tilt back valve output threshold calibration 802

Tilt forward valve calibration 803

Tilt forward valve output threshold calibration 803

Auxiliary valve direction A calibration 804

Auxiliary 1 or 2 direction A valve output threshold calibration 804

Auxiliary valve direction B calibration 806

Auxiliary 1 or 2 direction B valve output threshold calibration 806

Transmission calibration (Basic) 807

Prepare 807

Calibrations procedures 807

Transmission calibration (Advanced) 808

Calibrations procedures 808

Operator controls repair 813

Steering column repair 813

Description 813

Steering column assembly, remove 814

Battery disconnect 814

Remove operator controls from steering column 814

Remove covers, tilt only steering column 814

Remove covers, tilt and telescope steering column 815

Remove steering pump 816

Remove steering column assembly from truck 816

Steering column, disassemble 816

Tilt only 816

Tilt and telescope 816

Steering column, assemble 818

Tilt only 818

Tilt and telescope 818

Steering column assembly, install 818

Install steering column assembly in truck 818

Install steering pump 818

Install covers, tilt only steering column 818

Install covers, tilt and telescope steering column 818

Install operator controls on steering column 819

Connect battery 819

Display repair 819

Display remove and install 819

Remove 819

Install 820

Pinout descriptions for the 2 8-inch display 820

Pinout descriptions for the 5-inch display 821

Pinout descriptions for the 7-inch display 823

Operator buttons and switches repair 825

Park brake rocker switch 825

Remove 825

Install 825

Dash panel control module 825

Remove 825

Install 826

Cab Panel Control Module 826

Remove 826

Install 827

Mini-Lever Module 827

Remove 828

Install 828

Armrest assembly 828

Remove 828

Install 831

Rear drive handle with horn button 831

Remove 831

Install 832

Steering wheel horn switch 832

Remove 832

Install 833

Direction control lever (steering column) 833

Remove 833

Install 834

Turn signal lever 834

Remove 834

Install 836

Wiper control lever 836

Remove 836

Install 837

Battery disconnect switch 837

Remove 837

Install 838

Truck start switch 838

Keyed switch 838

Remove 838

Install 839

Keyless switch with Knob 839

Push button switch 840

Remove 840

Install 840

Push button with remote key switch 841

Remove 841

Install 841

Dome light switch 841

Remove 841

Install 842

E-hydraulic controls repair 842

E-hydraulic controls – TEST 842

Mini-levers 842

Full stroke test 842

Function returns to neutral test 842

Push (override) button 842

General 843

Mini-levers, remove and install 843

Armrest assembly 844

Remove 844

Install 846

Horn button 846

Remove 846

Install 846

Direction control switch 846

Remove 846

Install 847

Push (override) button 847

Remove 847

Install 848

Joystick controls repair 848

Joystick controls – TEST 848

Joystick levers 848

Full stroke test 848

Function returns to neutral test 849

General 850

Armrest assembly 850

Remove 850

Install 852

Joystick control levers 852

Remove 852

Install 852

Horn button 853

Remove 853

Install 853

Direction Control Switch 853

Remove 853

Install 854

550232099 8000YRM2305 (09 2023) US EN 857

Introduction 865

General 865

Truck handling and transport 866

How to move a disabled lift truck 866

How to Tow Lift Truck 866

How to put a lift truck on blocks 867

How to Raise Drive Tires 867

How to Raise Steering Tires 867

How to clean a lift truck 868

Putting a lift truck into storage 869

How to Put Internal Combustion Engine (ICE) Lift Trucks in Storage 869

Short-Term Storage 869

Long-Term Storage 870

While the Lift Truck is in Storage 870

How to Put Batteries in Storage 870

Preparing a stored lift truck for use 871

Putting a Stored Lift Truck Back Into Service 871

Wheels and tires 871

Periodic maintenance (PM) schedule 872

Daily periodic maintenance (PM) task schedule 872

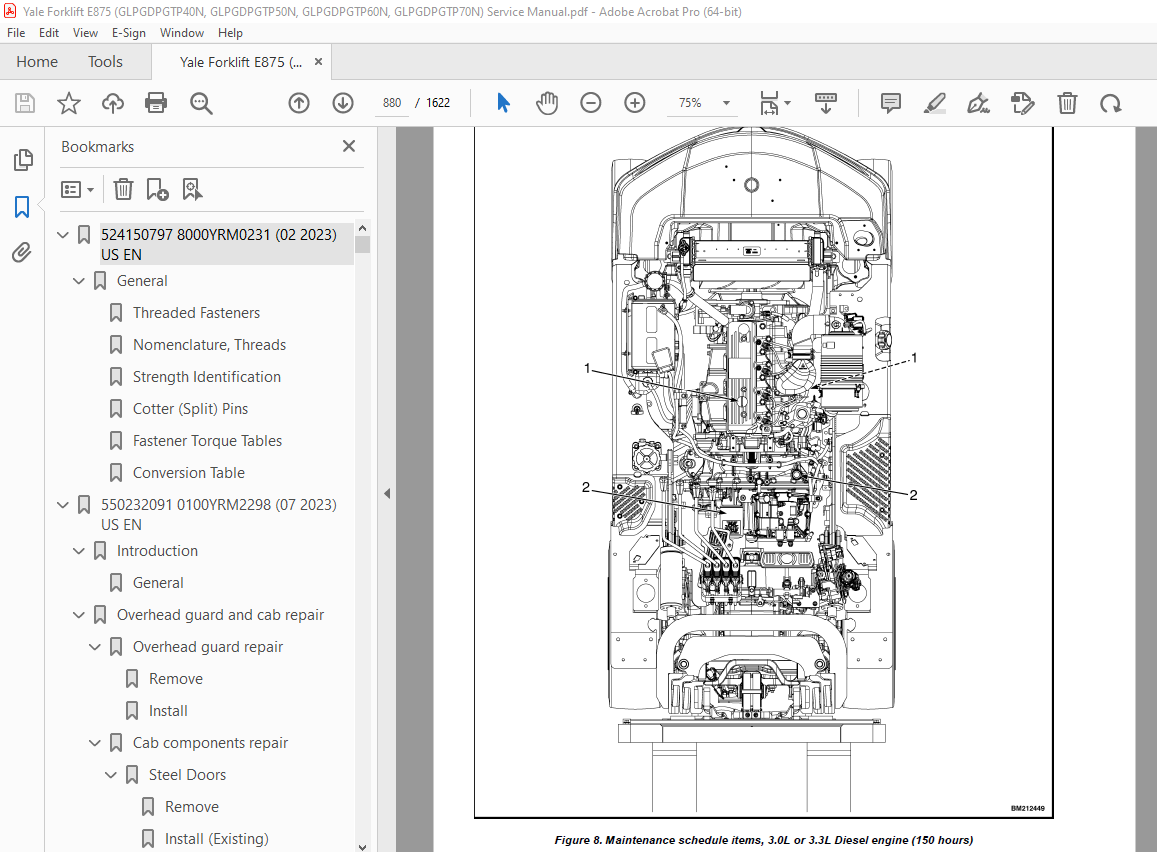

First 150 hours periodic maintenance (PM) schedule 878

Every 500 hour periodic maintenance (PM) schedule 882

Every 1000 hour periodic maintenance (PM) schedule 888

Every 2000 hour periodic maintenance (PM) schedule 893

Every 3000 hour periodic maintenance (PM) schedule 898

Every 4000 hour periodic maintenance (PM) schedule 901

Every 5000 hour periodic maintenance (PM) schedule 905

Every 6000 hour periodic maintenance (PM) schedule 909

Periodic maintenance (PM) procedures 911

Daily periodic maintenance (PM) task procedures 911

How to make checks with engine stopped 911

Tires and wheels 911

Safety labels 911

Mast, carriage, lift chains, header hoses, attachment 912

Visual Inspection of Mast, Mast Hardware, and Tilt Cylinder Hardware 912

Operator restraint system 913

Seat belt-operational checkout 913

Emergency Locking Retractor (ELR) 913

Seat adjustments 913

Non-Suspension Seat 913

Full-Suspension Seat 913

Air-Suspension Seat 913

Hood and seat latches 915

Engine compartment 915

Fuel, oil, and coolant leaks, check 915

Hydraulic hoses 915

Coolant hoses 915

Steering column gas cylinder 915

Transmission (Powershift) 916

Hydraulic system oil 916

Engine oil 916

Air filter 918

Forks 919

Inspect 919

Fuel Filter/Water Separator 921

How to make checks with engine running 921

Indicator lights, horn, fuses, and relays 922

Service brakes 923

Brake fluid level 923

Operation, check 923

Park brake, Dry Brake Axle 923

Park Brake, Wet Brake Axle 924

Engine oil pressure 924

Cooling system 925

Lift system, operate 926

Check lift height sensor 926

First 150 hours periodic maintenance (PM) procedures 926

Yanmar engine oil and oil filter, Yanmar 2 1L, 3 0L, 3 3L Diesel and Yanmar 2 2L LPG 926

Transmission oil level (Powershift) 929

Transmission oil filter (Powershift) 929

Dry brake axle differential and drive axle oil 930

Wet brake axle differential (center section) and wheel end oil 930

Drive shaft inspection 932

Tilt cylinder mounting hardware inspection 933

Every 500 hour periodic maintenance (PM) procedures 934

Hydraulic tank breather 934

Inspect 934

Battery 934

Yanmar LPG engine oil and oil filter 935

Yanmar diesel engine oil and oil filter 936

Clean debris from radiator core and oil cooler 938

Transmission oil level (Powershift) 939

Mast Lubrication 940

Mast pivot pins and bushings 941

Tilt Cylinder Adjustments 942

Header Hose Checks 943

Lift Chain Lubrication 944

Tilt Cylinder Lubrication 944

Master brake cylinder rod end pin lubrication 945

Manual control levers lubrication 945

Steer axle tie rod lubrication 945

Differential and drive axle oil 946

Park brake 947

Brake pedal linkage 947

Tilt cylinder mounting hardware inspection 947

Every 1000 hour periodic maintenance (PM) procedures 948

Yanmar 2 2L LPG engine oil and oil filter 948

Pedals 949

Manual hydraulic control levers 950

Levers and linkage 950

Hood 951

Hinges 951

Hood latch 951

Integral sideshift carriage, check bearings 952

Check bearings 952

Check lower mounting hooks 952

Lift Chain Lubrication 953

Measure chain wear 953

LPG vaporizer and fuel filter 955

LPG vaporizer 955

LPG fuel filter element replace 957

Remove 957

Install 957

Engine electrical system 958

Check connectors 958

Fuel filter/water separator 958

Intake and exhaust throttle valves, Yanmar 3 0L and 3 3L engines 958

Valve clearance adjustments, Yanmar 3 0L and 3 3L engines 958

Steer axle king pin lubrication 960

Dry brake axle differential and drive axle oil 960

Wet brake axle differential (center section) oil 961

Park brake inspection 962

LPG tank bracket latch lubrication 962

LPG tank bracket release 963

Drive shaft inspection 963

Every 2000 hour periodic maintenance (PM) procedures 964

Hydraulic Filter 964

Hydraulic tank breather 966

Inspect 966

Air cleaner 966

Transmission oil drain and fill (Powershift) 967

Transmission oil filter (Powershift) 967

Integral Sideshift Carriage 968

Remove bearings 968

Brake fluid change (master cylinder) 969

Service brakes (dry brake drive axle) 969

Check thickness 969

Dry brake axle differential and drive axle oil 970

Wet brake axle differential (center section) and wheel end oil 970

EGR cooler 971

EGR pipe and other connecting elbows 972

Dry brake drive axle wheel bearing 972

Steer axle wheel bearing 972

Every 3000 hour periodic maintenance (PM) procedures 972

Intake and exhaust throttle valves, Yanmar 2 1L Diesel and 2 2L LPG Engines 972

Valve Clearance Adjustments, Yanmar 2 1L Diesel and 2 2L LPG Engines 972

Every 4000 hour periodic maintenance (PM) procedures 974

Cooling system 974

Coolant drain and flush 974

Coolant fill 975

Hydraulic Oil, Replace 976

Spark plugs, Yanmar 2 2L LPG engine 976

Every 5000 hour periodic maintenance (PM) procedures 976

V-belt (drive belt) 976

Auto tensioner 977

Every 6000 hour periodic maintenance (PM) procedures 978

DPF, Yanmar 2 1L diesel engine 978

PCV valve 978

550232100 8000YRM2306 (09 2023) US EN 981

Introduction 987

General 987

Covers, floorplates, and counterweight 988

Covers repair 988

Hood 988

Remove 988

Install 989

Steering column covers 990

Remove 990

Install 991

Kick panels 991

Remove 991

Install 993

Floormats and floorplates 993

Remove 993

Install 994

Dash covers 994

Remove 994

Install 995

Heating, Ventilation and Air Conditioning (HVAC) unit covers 995

Remove 995

Install 997

Counterweight repair 997

Counterweight Repair 997

Remove 997

Install 1001

LPG tank bracket repair 1002

LPG Tank Bracket Repair 1002

Fixed Bracket 1002

Remove 1002

Install 1003

Swing-Out Bracket 1003

Remove 1003

Install 1004

Swing-Out and Drop-Down Bracket 1005

Remove 1005

Install 1005

Frame repair 1007

Frame module repair 1007

Fuel tank repair 1007

Inspect 1007

Clean 1007

Steam method of cleaning 1008

Chemical solution method of cleaning 1008

Additional preparations for repair 1009

Small leaks, repair 1009

Large leaks, repair 1009

Preparations for use after repair 1009

Hydraulic oil tank repair 1009

Inspect 1009

Clean 1010

Steam method of cleaning 1010

Chemical solution method of cleaning 1011

Additional preparations for repair 1011

Small leaks, repair 1011

Large leaks, repair 1011

Preparations for use after repair 1011

Frame checks and adjustments 1011

Paint and labels 1012

General painting concerns 1012

Label replacement 1012

Tires and wheels 1017

Wheel and tire overview 1017

Snap-on wheel removal and replacement 1017

Snap-On-Tire, Change 1017

Remove Snap-On-Tire, Solid Tire From Wheel 1018

Install Snap-On-Tire, Solid Tire on Wheel 1019

Pneumatic tire removal and replacement (with tube) 1020

Remove wheels from lift truck 1020

Remove tire from wheel 1020

Remove Tire From Two-Piece Wheel 1021

Remove Tire From Three and Four-Piece Wheels 1022

Install wheel in tire 1023

Install Three-Piece or Four-Piece Wheel in Tire 1023

Add air to pneumatic tires with tube 1025

Install the wheels 1026

Pneumatic tire removal and replacement (without tube) 1027

Remove wheels from lift truck 1027

Remove Tire From Wheel 1027

Install Tire on Wheel 1029

Add Air to Pneumatic Tubeless Tire 1031

Wheels, Install 1032

Solid pneumatic tire repair and replacement 1032

Solid Rubber Tires on Pneumatic Wheels, Change 1032

Remove Tire From Wheel 1032

Install Tire on Wheel 1033

Optional features 1036

Debris screen 1036

Remove 1036

Install 1036

String cutter 1036

Remove 1036

Install 1037

550232101 8000YRM2307 (06 2023) US EN 1039

Introduction 1045

General 1045

Electrical schematics and diagrams 1046

Electrical schematics 1046

Hydraulic schematics 1084

Hydraulic Schematics – Transmission 1084

Hydraulic schematics – manual hydraulics with Powershift transmission 1089

Hydraulic schematics – e-hydraulics with Powershift transmission 1091

Hydraulic schematics – manual hydraulics with Hydrostatic transmission 1093

Hydraulic schematics – e-hydraulics with Hydrostatic transmission 1093

550232102 8000YRM2308 (08 2023) US EN 1095

Introduction 1109

General 1109

Frame 1110

Frame modular design description 1110

Frame attaching hardware description 1111

Hydraulics 1113

Hydraulic supply and return description 1113

Hydraulic Supply and Return 1113

Hydraulic pump description 1116

Hydraulic Pump 1116

Control valve description 1119

Control Valve 1119

Manual Control Valve 1119

Electro-Hydraulic Control Valve 1120

Manual Valve Main Components 1122

Control Valve Schematic 1122

Valve Section Breakdowns 1123

Inlet/Steer Section – Neutral/Steering Idle 1123

Inlet Section – Steering 1124

Lift Section – Neutral 1124

Lift Section – Neutral 1124

Lift Section – Lower 1125

Lift Section – Lower 1125

Lift Section – Raise 1126

Lift Section – Raise 1126

Tilt Section – Neutral 1127

Tilt Section – Spool IN 1127

Tilt Section – Spool OUT 1128

AUX 1 Section – Neutral 1128

AUX 1 Section – Spool IN 1129

AUX 1 Section – Spool OUT 1129

AUX 2 Section – Neutral 1130

AUX 2 Section – Spool IN 1130

AUX 2 Section – Spool OUT 1131

Unloader in Neutral – FDP 1131

Unloader in Function – FDP 1132

Anti-Stall Functionality 1132

Steering control unit description 1133

Steering Control Unit (SCU) 1133

Operation 1134

Brake system description 1137

Brake System Description 1137

Dry Brakes 1137

Master Cylinder 1139

Brake Position Sensor 1140

Wet Brakes 1140

Park Brake 1142

MONOTROL® Directional Control 1143

Inch Brake/Service Brake Pedal 1143

Electrical system 1145

Controller description 1145

Controller Description 1145

VSM 1145

OBox (Output Box) 1150

IBox (Input Box) 1152

Display (User Interface) 1155

Smart Antenna 1160

Impact Sensor 1162

Dash and Cab Switch Bank (Control Module) 1163

Mini-Lever Module (MLM) 1164

Hydro Static Transmission (HST) Controller 1166

Main Power Distribution Module (PDM) 1167

Power distribution module (PDM) description 1169

Power Distribution Module (PDM) 1169

Fuse and Relay Descriptions 1172

PDM Pin Out 1173

PDM Electrical Schematic 1175

Sensors description 1177

Sensors 1177

Operator Compartment 1177

Operator Presence Sensor (OPS) 1177

Steering Wheel Sensor 1178

Ambient Light Sensor 1178

Proximity Sensor 1179

Object Detection Sensors (Side) 1181

Objection Detection Sensor (Rear) 1181

Brake Pressure Sensor 1182

Service Brake Pedal Position Sensor 1183

E-Brake Position Sensor 1183

Park Brake Position Sensor 1184

Brake Fluid Level Sensor 1185

Accelerator Pedal Position (APP) Sensor 1185

Load Weight Sensor 1186

Frame 1186

Impact Sensor 1187

Steer Axle Position Sensor 1187

Mast 1188

Mast Lift Height Sensor (Discrete) 1188

Mast Height Sensor (Continuous) 1189

Mast Tilt Sensor 1189

Transmission Sensors 1190

Transmission Output Shaft Sensor (TOSS) 1190

Pressure Sensor 1191

Temperature Sensor 1191

Fuel 1192

Fuel Water Separator Sensor 1192

Fuel Level Sensor (Gas and Diesel Engines) 1192

LPG Tank Bracket Sensor 1193

Fuel Quality Sensor (FQS) – LPG and Dual Fuel Engines 1194

Engine 1195

Air Filter Restriction Sensor 1197

Throttle Position Sensor (TPS) 1197

Oil Pressure Sensor 1197

Engine Coolant Temperature (ECT) Sensor 1197

Engine Speed Sensor 1198

Low Coolant Level Sensor 1198

Exhaust System 1199

Heated Oxygen Sensor 1199

Exhaust Gas Temperature (EGT) Sensor 1199

EGR Temperature Sensor 1199

EGR Pressure Sensor 1199

Controller area network (CAN) description 1200

Controller Area Network (CAN) 1200

Operation 1200

Standard CAN 1201

Identifier Fields 1201

Message Types 1202

Multiple CANs 1202

CAN1 (Vehicle Bus) 1202

CAN2 (DriveTrain Bus) 1203

CAN3 (Front End) 1203

CAN4 (Service) 1204

CAN Failure 1204

Display description 1204

Display Description 1204

2 8-Inch Display 1204

5- or 7-Inch Display 1205

Electrical Specifications 1206

Wake Up 1206

Wake Up Output 1206

Memory Support 1206

Display Viewing 1207

Ambient Light Sensor 1207

Video Inputs 1207

Controller CAN Communications 1207

5-Button Keypad 1207

Male Connector Polarities 1208

2 8-Inch Display 1208

5-Inch Display 1210

7-Inch Display 1212

Battery description 1214

Battery Overview 1214

Battery Types 1215

Conventional 1215

Maintenance-Free 1215

Battery Charging 1215

Fast Charging 1216

Slow Charging 1216

Battery Disconnect Switch (Optional) 1216

Battery Charge Dongle (Optional) 1217

Lights description 1218

Lights 1218

Pedestrian Awareness Lights 1218

Orange Strobe Light 1218

Red or Blue Spot Lights 1219

Red LED Pedestrian Awareness Perimeter Lights 1220

Work Lights 1221

Front or Rear or Both 1221

Mast Mounted 1222

Brake, Tail, Reverse, Turn Signals, Hazard 1223

Brake Lights (Red) 1224

Tail Lights (Red) 1224

Turn Signals (Amber) 1224

Hazard 1224

Reverse Lights (White) 1224

Fork Laser Level Light (Line) 1224

Interior Reading Light (Cab Only) 1225

Software description 1225

Software Description 1226

Configuration Data File (CDF) 1226

Display Application (Program) 1226

Vehicle System Manager (VSM) Application (Program) 1226

Service Tools 1226

PC Service Tool (PCST) 1226

System Requirements 1227

Main Screen 1227

Field Prog Programming Tool 1228

Yanmar Smart Assist Direct (SAD) Tool (Engine) 1230

System Requirements 1230

ECU Replacement or Update 1231

Telemetry system description 1232

General 1232

Telemetry Module 1236

Basic Operations 1237

ID Card / ID Reader 1237

Interlock Relay 1238

Buzzer 1238

Wakeup 1238

Checklist 1238

Dynamic Stability System (DSS) 1238

Components of the DSS 1239

Vehicle System Manager (VSM) 1239

Lift Height Sensor 1239

Hydraulic Load Sensor 1239

Tilt Angle Sensor 1240

Tilt Override Button 1240

Speed Sensor 1240

Steer Angle Sensor 1240

DSS Subsystems 1240

Lateral Stability System 1240

High-Lift Traction Control 1240

High-Lift Tilt Control 1240

Corner Control 1241

DSS indicators and events 1241

Visual indicators 1242

Audible indicator 1243

Telemetry 1243

Operator’s cab 1244

Overhead guard description 1244

Overhead Guard 1244

Cab components description 1246

Cab Components 1246

Doors 1246

Steel Doors 1247

PVC Doors 1247

Screens 1249

Front Screen 1249

Top (Roof) Screen 1249

Rear Screen 1249

Wipers 1250

Front Screen and Wiper 1250

Top Screen and Wiper 1251

Rear Screen and Wiper 1252

Washer Fluid Tank and Supply Lines 1253

Heating and Cooling 1254

HVAC Controls 1260

Front and Rear Work Lights 1261

Strobe Light 1261

Operator Fan 1261

Front Grab Handle 1261

Rear Drive Handle with Horn Button 1262

12 Volt Power Supply with 2 USB Charging Ports 1262

12 Volt Auxiliary Wire Harness 1263

Reading (Dome) Light 1264

Seat description 1264

Seat Description 1264

Non-Suspension 1265

Semi-Suspension 1265

Full Suspension 1266

Air Ride Full Suspension 1266

Serviceable Parts 1266

Seat Belts 1266

Operator Presence Sensor (OPS) 1266

Operator controls description 1268

Operator Controls Description 1269

LCD Display (User Interface) 1269

Radio Frequency IDentification (RFID) Card Reader 1269

Steering Wheel and Horn 1270

Manual Hydraulic Levers 1270

Mini-Lever Module (MLM) Hydraulic Levers 1271

Joystick Hydraulic Controls 1271

Wiper Lever 1272

Turn Signal Lever 1273

Direction (FNR) Lever 1274

Dash and Cab Control Modules 1274

Manual Park Brake and Release 1275

Park Brake Rocker Switch (Optional) 1276

Accelerator Pedal 1276

Foot Direction Control (FDC) 1276

Dual Pedal Direction Control 1277

Keyed Ignition Switch 1277

Keyless Ignition Switch 1278

Pushbutton Ignition Switch 1278

Operator Seat 1279

Dome Light and Rocker Switch 1279

Rear Drive Handle with Horn Button 1280

Driver’s Fan and Fire Extinguisher 1280

Drivetrain 1281

Diesel engine description 1281

General Engine Information 1281

Combustion Theory 1281

Engine Block 1282

Camshaft and Timing Set 1284

Cylinder Head 1285

Valve Train 1287

Manifolds 1287

Intake 1287

Exhaust 1287

Air Cleaner/Filter 1288

Diesel Fuel System 1288

Electronic Fuel Injection (EFI) 1289

Positive Crankcase Ventilation (PCV) 1289

Battery Construction 1290

Conventional Standard Battery 1290

Maintenance-Free Battery 1291

Battery Charging 1291

Battery Fast Charging 1291

Battery Slow Charging 1292

Starting System Principles of Operation 1292

Starting System Components – Ignition Switch 1292

Starting System Components – Starter Solenoid 1292

Starting System Components – Flywheel and Ring Gear 1293

Starting System Components – Starter and Motor Drive 1293

Charging System – General 1295

Charging System – Regulator 1295

Charging System – Theory 1295

Exhaust Aftertreatment 1296

Description and Operation 1296

Diesel Particulate Filter (DPF) – Yanmar 1296

Yanmar Diesel Engine 1298

Yanmar Diesel Fuel System 1299

Fuel Water Separator 1300

Supply Pump 1301

Common Rail 1301

Injector 1301

Crankshaft Rotation Sensor and Gear Speed Sensor 1301

ECU 1301

Engine Mechanical 1302

Engine Cooling 1303

Engine Oil 1305

Engine Main Electronic Control Components 1306

Engine Control Unit (ECU) 1307

Fuel Feed Pump 1307

Fuel Pump (Supply Pump) 1307

Common Rail 1308

Fuel Injector 1308

Exhaust Gas Recirculation (EGR) valve 1308

Diesel Particulate Filter (DPF) 1309

Intake Throttle 1309

Exhaust Throttle (Optional) 1309

Accelerator Pedal Position (APP) Sensor 1310

Engine Coolant Temperature Sensor 1310

Crankshaft Rotation Sensor 1310

Gear Speed Sensor 1310

New Air Temperature Sensor 1311

Exhaust Gas Recirculation (EGR) Temperature Sensor 1311

EGR (EGR) Pressure Sensor 1311

Intake Air Temperature Sensor 1312

Engine Coolant Thermostat 1312

DPF Inside/Inlet Temperature Sensors 1313

DPF Differential Pressure Sensor 1313

Fuel Rail Pressure Sensor 1314

Engine ECU Management Controls 1314

Cold Start Assist 1314

Droop Control 1314

Isochronous Control 1314

Low-Idle Speed Up 1315

Turbocharger Protection (at low temperature) 1315

High-Idle Speed Reduction at Low Temperature (optional) 1315

Auto Idle Speed Reduction (optional) 1315

DPF Regeneration Control 1315

Self-Regeneration 1315

Assisted Regeneration 1315

Reset Regeneration 1315

Manual (Stationary) Regeneration 1315

Diagnostic Tool Tests and Adjustments 1315

EGR Active Control 1315

Exhaust Gas Throttle Active Control 1315

Intake Air Throttle Active Control 1315

LPG engine description 1315

Engine coolant system 1315

Engine oil 1316

Fuel system 1317

Vaporizer 1320

Balancing line 1320

Fuel rail 1320

Injector 1320

Crankshaft speed sensor and cam speed sensor 1320

Gas temperature pressure sensor 1320

ECU 1320

Engine trouble caused by improper fuel 1320

Fuel properties and engine performance 1320

Bi-fuel engine description 1321

CNG engine description 1321

Powershift transmission description 1321

Powershift Transmission 1321

Mechanical Overview 1321

Engine 1321

Torque Converter 1321

Stator 1322

Turbine 1322

Transmission 1323

Single-Speed 1325

Clutch Packs 1326

Forward Operation 1328

Reverse Operation 1328

Transmission Hydraulic Schematic 1328

Transmission Oil Flow 1332

Control Valve Oil Flow 1332

Control Valve 1333

Torque Converter Regulator 1335

Electrical System Architecture 1335

Transmission Input Shaft Speed (TISS) 1337

Transmission Output Shaft Speed (TOSS) 1338

Transmission Oil Temperature Sensor 1339

Accelerator Pedal Position (APP) Sensor 1339

Electrical Control Schematic 1340

Transmission Operational Modes 1342

Powered Off Mode 1342

Neutral Interlock Mode 1342

Normal Mode 1342

Fault Mode 1342

Pack Braking Mode 1342

Inching Mode 1342

Transmission Output Gear Yoke and Driveshaft 1342

Transmission, Driveshaft, and Drive Axle 1343

Hydrostatic transmission description 1344

Wet brake axle description 1344

Dry brake axle description 1344

Dry Brake Axle 1344

Synchronous steer axle description 1349

Synchronous Steering 1349

Operation 1350

Components 1350

Steering Wheel Sensor 1350

Steer Axle Position Sensor 1350

Calibration 1351

Synchronous Steering Hydraulic Schematic 1351

Non-synchronous steer axle description 1352

Non-Synchronous Steer Axle 1352

Steer Axle Components 1353

Top Bushing Blocks 1354

Center Pivot Mount Bushings 1354

Steer Axle Mounting Brackets 1354

Steering Cylinder 1354

Tie Rods 1354

Spindle Assembly 1355

Wheel Hub 1355

Powertrain Protection System 1355

Cooling 1357

Fan description 1357

Fan (Radiator Cooling) 1357

Crankshaft Belt Drive Fan 1357

Hydraulic Belt Drive Fan 1357

Cooling system description 1358

Cooling System 1358

Radiator 1359

Radiator Cap 1360

Cooling Fan 1360

Thermostat 1360

Coolant Pump 1361

Coolant Recovery Reservoir 1361

Coolant 1362

Radiator description 1362

Radiator 1362

Radiator Cap 1363

Charge Air Cooler (CAC) 1363

Radiator Screen (Optional) 1363

Front end 1364

Fork description 1364

Fork Description 1364

Fork Inspections and Service 1365

Fork Classification 1365

Fork Terminology 1366

Fork Tip Options 1368

Fork Bevel Options 1369

Fork Taper Options 1369

Fork Identification 1370

Miscellaneous Forks 1370

Standard Carriage and Forks 1370

Carriage description 1371

Carriage Description 1371

Carriage Classification 1371

Standard Carriage 1372

Load Backrest (LBR) Extension 1373

Integral Sideshift (ISS) Carriage 1375

Integral Sideshift Carriage with Fork Positioner (ISSFP) 1376

Mast description 1377

Mast Overview 1377

2-stage limited free lift (LFL) mast description 1378

2-stage LFL mast description 1378

Basic Operation 1380

Two Stage Limited Free-Lift 1381

Mast Hydraulic Components 1386

Two Stage LFL Header Hose 1386

Main Lift Cylinders 1388

Mast Hose Manifold 1389

Velocity Fuse 1389

Hoses and Hose Assemblies 1389

Hose Fittings 1389

Mast Mechanical Components 1390

Lift Chain 1390

Chain Anchors 1390

Chain Sheaves 1391

Load Rollers 1391

Wear Strips 1392

Mast Mounting Bushings 1392

2-stage full free lift (FFL) mast description 1392

2-stage FFL mast description 1392

Basic Operation 1394

Two Stage Full Free-Lift 1395

Mast Hydraulic Components 1401

Two Stage FFL Header Hose 1401

Free-Lift and Main Lift Cylinders 1403

Mast Hose Manifold 1404

Velocity Fuse 1405

Hoses and Hose Assemblies 1405

Hose Fittings 1405

Mast Mechanical Components 1405

Lift Chain 1405

Chain Anchors 1406

Chain Sheaves 1407

Load Rollers 1407

Wear Strips 1408

Mast Mounting Bushings 1408

3-stage full free lift (FFL) mast description 1409

3-Stage FFL mast description 1409

Basic Operation 1411

Three Stage Full Free-Lift 1412

Mast Hydraulic Components 1420

Three Stage FFL Header Hose 1420

Free-Lift and Main Lift Cylinders 1422

Mast Hose Manifold 1423

Velocity Fuse 1424

Hoses and Hose Assemblies 1424

Hose Fittings 1424

Mast Mechanical Components 1424

Lift Chain 1424

Chain Anchors 1425

Chain Sheaves 1426

Load Rollers 1426

Wear Strips 1427

Mast Mounting Bushings 1427

4-stage full free lift (FFL) mast description 1428

Paper roll clamp description 1428

Bale clamp description 1428

Rotator description 1428

550232103 8000YRM2309 (06 2023) US EN 1431

Introduction 1437

General 1437

Truck vital measurements 1438

Weight specifications 1438

Lift truck lifting capacity 1438

Counterweight weights 1438

Speed specifications 1438

Engine speeds 1438

Mast lower speeds 1439

Carriage lifting speeds with metric rated load at governed RPM and 55°C oil temperature (+/- 5%) 1439

Front end equipment max drift speeds* 1439

Dimension specifications 1440

Tire sizes 1440

Mast tilt specifications 1441

Pressure specifications 1441

Hydraulic system pressure specifications 1441

Coolant system pressure specifications 1441

Steering system pressure specifications 1441

Tire pressure specifications 1442

Transmission oil specifications 1442

Engine operation specifications 1443

Engine operation specifications 1443

Fluid specifications and capacities 1444

Fuel specifications and capacities 1444

Fuel tank capacity 1444

Lubricant specifications and capacities 1445

Engine oil 1445

Hydraulic tank oil 1445

Transmission oil 1446

Brake fluid 1446

Dry brake axle 1446

Wet brake axle 1446

Coolant specifications and capacities 1447

Cooling capacity 1447

Torque specifications 1448

Frame torque specifications 1448

Energy, electrical, and controls systems torque specifications 1448

Front end torque specifications 1448

Carriage 1448

Mast 2 stage FFL 1449

Mast 3 Stage FFL 1449

Mast 2 stage LFL 1449

Hydraulic torque specifications 1449

Operator station torque specifications 1450

Rectangle overhead guard 1450

Figure 8 overhead guard 1450

Drivetrain torque specifications 1451

Engine – Yanmar 2 1L Diesel 1451

Engine – Yanmar 2 2L LPG 1452

Transmission 1453

Drive axle (Dry Brake) 1453

Drive axle (Wet Brake) 1454

Brakes 1454

Park brake 1454

Steering axle 1454

550232104 8000YRM2310 (06 2023) US EN 1457

Error code reference charts 1463

Vehicle system manager (VSM) error code reference chart 1463

Engine error code reference chart 1477

Transmission error code reference chart 1565

Drive axle error code reference chart 1576

Front end error code reference chart 1582

Operator station error code reference chart 1597

Power supply error code reference chart 1605

Calibration error code reference chart 1615

Steering error code reference chart 1617

Hydraulic fan drive error code reference chart 1619