$40.95

Yale Forklift F807 (ERP030_035_040TH) Service Manual – PDF DOWNLOAD

Yale Forklift F807 (ERP030_035_040TH) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift F807 (ERP030_035_040TH) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1014

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift F807 (ERP030_035_040TH) Service Manual – PDF DOWNLOAD

524150790-2100YRM0103-(03-2007)-UK-EN 1

toc 1

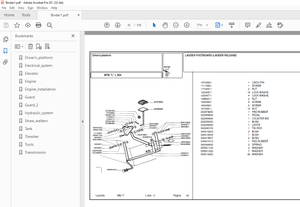

Tilt Cylinders 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Tilt Cylinder Repair 5

Remove 5

Disassemble 5

Clean 5

Assemble 6

Tilt Cylinders With O-Ring or Single-Lip Seals 6

Tilt Cylinders 7

Install 8

Tilt Cylinder Leak Check 10

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 11

Torque Specifications 11

Piston Rod Nut 11

Retainer 11

Troubleshooting 12

tables 1

Table 1 Movement Rates (Maximum) for Tilt Cylinders 10

524150797-8000YRM0231-(02-2023)-UK-EN 17

General 23

Threaded Fasteners 23

Nomenclature, Threads 23

Strength Identification 24

Cotter (Split) Pins 25

Fastener Torque Tables 30

Conversion Table 32

524150797-8000YRM0231-(03-2020)-UK-EN 39

General 43

Threaded Fasteners 43

Nomenclature, Threads 43

Strength Identification 44

Cotter (Split) Pins 45

Fastener Torque Tables 50

Conversion Table 52

524158039-0620YRM0294-(09-2016)-UK-EN 59

General 63

Brush and Commutator Inspection 64

Hydraulic Pump Motor and Traction Motor 64

Steering Pump Motor 67

Normal Commutator Surface 67

Commutator Problems 67

Brush Replacement 72

Stoning the Commutator 75

Motors Repair 76

Disassemble 77

Traction Motor and Hydraulic Pump Motor 77

Steering Pump Motor 78

Assemble 82

Traction Motor and Hydraulic Pump Motor 82

Steering Pump Motor 84

Brush Alignment, Traction and Hydraulic Motors 86

Tests for Damaged Field and Armature 87

Test for an Open Circuit in One Armature Winding 87

Test for Short Circuit in One Armature Winding 87

Test for Short Circuit to Armature Shaft 88

Test for Open Circuit in Field Coil 88

Test for Short Circuit in Field Coil 89

Test for Short Circuit Between Field and Motor Case 89

Brush Holder Test 89

Troubleshooting 90

524158040-2240YRM0001-(01-2023)-UK-EN 95

General 101

Battery Type 101

Lead-Acid Batteries 101

Lithium-Ion Batteries 102

Specific Gravity 102

Chemical Reaction in a Cell 102

Electrical Terms 104

Battery Selection 105

Battery Voltage 106

Battery as a Counterweight 106

Battery Ratings 106

Kilowatt-Hours 106

Battery Maintenance 107

Safety Procedures 107

Maintenance Records 107

New Battery 107

Cleaning Battery 108

Adding Water to Battery 110

Hydrometer 110

Battery Temperature 111

Charging Battery 112

Types of Battery Charges 113

Methods of Charging 114

Troubleshooting Charger 115

Knowing When Battery Is Fully Charged 115

Where to Charge Batteries 115

Equipment Needed 115

Battery Connectors 116

Battery Care 116

Troubleshooting 118

524158040-2240YRM0001-(03-2020)-UK-EN 123

General 127

Battery Type 127

Lead-Acid Batteries 127

Lithium-Ion Batteries 128

Specific Gravity 128

Chemical Reaction in a Cell 128

Electrical Terms 130

Battery Selection 130

Battery Voltage 131

Battery as a Counterweight 132

Battery Ratings 132

Kilowatt-Hours 132

Battery Maintenance 132

Safety Procedures 132

Maintenance Records 133

New Battery 133

Cleaning Battery 133

Adding Water to Battery 135

Hydrometer 136

Battery Temperature 137

Charging Battery 138

Types of Battery Charges 138

Methods of Charging 140

Troubleshooting Charger 140

Knowing When Battery Is Fully Charged 141

Where to Charge Batteries 141

Equipment Needed 141

Battery Connectors 142

Battery Care 142

Troubleshooting 144

524158890-4000YRM0521-(03-2006)-UK-EN 149

toc 149

Mast 149

Safety Precautions Maintenance and Repair 150

General 153

Description and Operation 153

Carriages 153

Mast Mounts 155

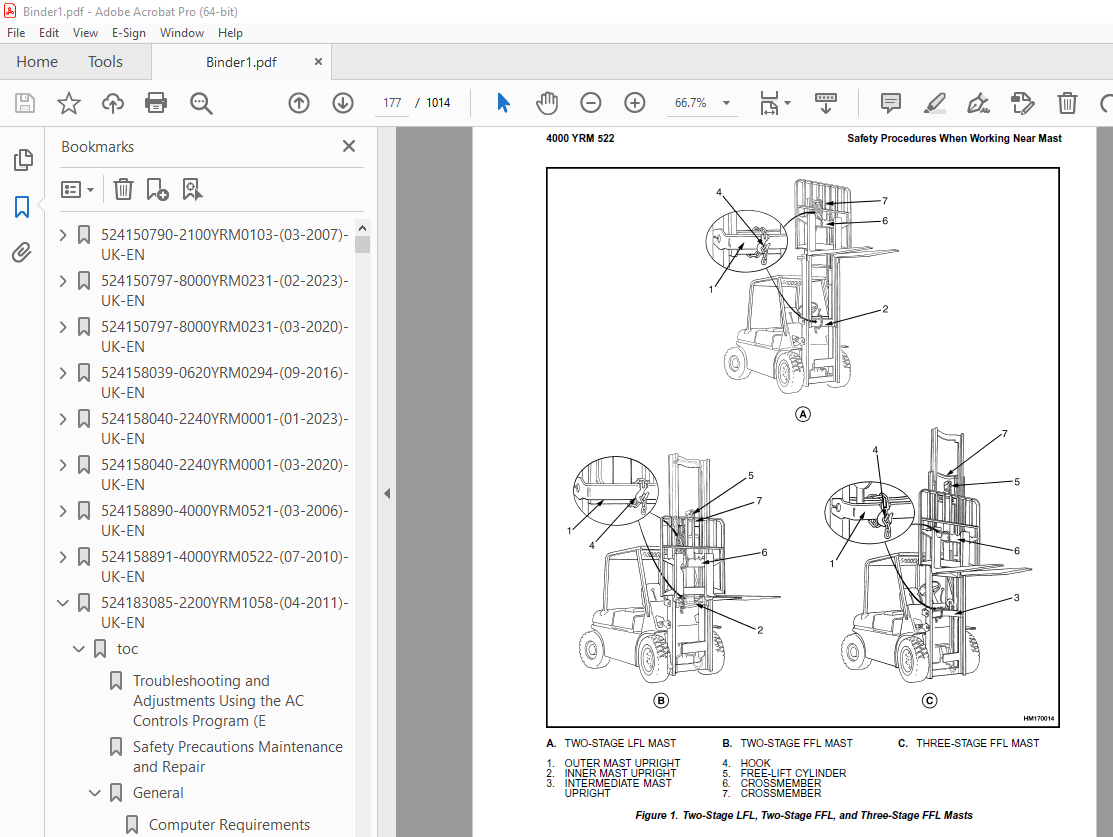

Two-Stage Mast, Limited Free-Lift (LFL) 156

Description and Operation 156

Two-Stage Mast, Full Free-Lift (FFL) 158

Description and Operation 158

Three-Stage Mast, Full Free-Lift (FFL) 160

Description and Operation 160

Four-Stage Mast 162

Description and Operation 162

Cylinder Cushion During Lifting Sequence 166

Cylinder Cushion During Lowering Sequence 167

524158891-4000YRM0522-(07-2010)-UK-EN 171

toc 171

Mast 171

Safety Precautions Maintenance and Repair 172

General 175

Safety Procedures When Working Near Mast 176

Fork Repair 178

Remove 178

Install 178

Carriages Repair 180

Standard Carriage, Remove 180

Hang-On Sideshift Carriage, Remove 181

Standard Carriage and Hang-On Sideshift Carriage, Repair 182

Standard Carriage, Install 183

Hang-On Sideshift Carriage, Install 184

Integral Sideshift Carriage 184

Remove 184

Clean and Inspect 188

Repair 189

Install 190

Mast Repair 191

Remove 191

Two-Stage LFL and Two-Stage FFL Masts, Disassemble 193

Three-Stage FFL Mast 201

Disassemble 201

Mast and Chains, Clean and Inspect 204

Two-Stage LFL and Two-Stage FFL Mast, Assemble 205

Three-Stage FFL Mast, Assemble 206

Install 207

Lift Cylinders Repair 209

Main Lift Cylinders, Remove 209

Free-Lift Cylinder, Remove 209

Cylinders, Disassemble 210

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 210

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 212

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 212

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 213

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 214

Clean and Inspect 215

Cylinders, Assemble 215

Two-Stage Full Free-Lift Mast, Right-Hand Main Lift Cylinder 215

Two-Stage Full Free-Lift Mast, Left-Hand Main Lift Cylinder 216

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 217

Two-Stage Limited Free-Lift Mast and Three-Stage Full Free-Lift 217

Two-Stage Full Free-Lift Mast and Three-Stage Full Free-Lift Mas 218

Main Lift Cylinders, Install 219

Free-Lift Cylinder, Install 219

Header Hose Arrangements 220

Two-Stage LFL Mast, New Hose Install 220

Two-Stage LFL Mast, Adjust Hoses After Installation 225

Two-Stage FFL Mast, New Hose Install 225

Two-Stage FFL Mast, Adjust Hoses After Installation 233

Three-Stage FFL Mast, New Hose Install 233

Three-Stage FFL Mast, Adjust Hoses After Installation 244

Header Hose Arrangement 245

Two-Stage LFL Mast, New Hose Install 245

Two-Stage LFL Mast, Adjust Hoses After Installation 250

Two-Stage FFL Mast, New Hose Install 250

Two-Stage FFL Mast, Adjust Hoses After Installation 256

Three-Stage FFL Mast, New Hose Install 256

Three-Stage FFL Mast, Adjust Hoses After Install 265

Lift and Tilt System Leak Check 266

Lift Cylinders Leak Check 266

Tilt Cylinders Leak Check 266

Tilt Cylinders Adjustment 267

Lift Chains Adjustment 269

Mast Adjustment 271

Carriage Adjustment 273

Troubleshooting 274

tables 171

Table 1 Hook-Type Carriage Chain Adjustment 269

Table 2 Pin-Type Carriage Chain Adjustment 270

524183085-2200YRM1058-(04-2011)-UK-EN 277

toc 277

Troubleshooting and Adjustments Using the AC Controls Program (E 277

Safety Precautions Maintenance and Repair 278

General 281

Computer Requirements 281

Software, Install 281

Language Selection 281

Demo Mode 282

Connect PC to Lift Truck 286

Starting AC Controls Program 288

Lift Truck Control Setup 293

Change Lift Truck Serial Number or Hourmeter 293

Setting Factory Default Values or Changing Lift Truck Parameters 294

Create New Custom Lift Truck Configuration 300

Lift Truck Configuration Properties 303

Import New Lift Truck Configuration From Disk 306

Delete Custom Lift Truck Configuration or Password File 308

Dash Display 311

Custom Display Languages 311

Download Display Language 313

Clear Operator Log 313

Password Functions 316

Enable/Disable Password and Lift Truck Inspection Functions 316

Truck Inspection Checklist 316

Password 316

Password Properties 316

Create New Password File 321

Download Passwords 322

Upload Passwords 324

Reports Menu 326

Devices Report 326

Custom Report 326

Password Report 326

Operator Report 333

Current Settings Report 336

Status Code Report 340

Status Codes Log 343

Troubleshooting 345

Diagnostics 345

Help Menu 348

General 348

Contents 348

Technical Support 348

About Electric Truck AC Controls Program 348

524204497-0100YRM1073-(06-2004)-UK-EN 355

toc 355

Frame 355

Safety Precautions Maintenance and Repair 356

Introduction 359

General 359

Description of Operation 359

Discharging the Capacitors 360

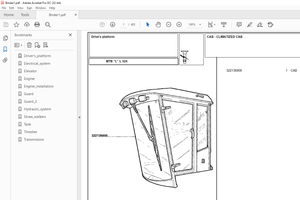

Covers and Floor Plates 361

Overhead Guard Repair 363

Remove 363

Install 363

Hood and Seat Assembly 364

Remove 365

Install 365

Counterweight 366

Remove 366

Install 367

Safety Labels 368

Painting Instructions 371

524204498-1300YRM1074-(07-2009)-UK-EN 375

toc 375

Transaxle 375

Safety Precautions Maintenance and Repair 376

Introduction 379

General 379

Discharging the Capacitors 379

Description 381

Transmission 381

Traction Motor 381

Maintenance 382

Oil Level Check 382

Oil Change 382

Transaxle Assembly 383

Remove 383

Disassemble 384

Traction Motor and Covers 384

Brake Assembly and Gears 386

Planetary Gears and Drive Axle 387

Clean and Inspect 388

Assemble 389

Planetary Gears and Drive Axle 389

Brake Assembly and Gears 390

Traction Motor and Covers 391

Install 393

Troubleshooting 394

tables 375

Table 1 Special Tools 391

Table 2 Conventional Tools 391

524204499-1600YRM1075-(02-2008)-UK-EN 397

toc 397

Steering System 397

Safety Precautions Maintenance and Repair 398

Introduction 401

General 401

Discharging the Capacitors 401

Description of Operation 403

Steering Pressure Check 403

Operation Check 404

Steering Wheel and Column 405

Steering Column Covers 405

Remove 405

Install 405

Steering Column Components 406

Remove 406

Install 409

Steering Control Unit Assembly 410

Power Steering Pump and Motor 410

Description 410

Remove 410

Install 411

Disassemble 413

Assemble 414

Steering Actuator Components 414

Steer Tire and Wheel Assembly 414

Remove 414

Install 414

Wheel Hub Assembly 415

Remove 415

Install 415

Steering Axle Assembly 415

Remove 415

Clean 417

Install 417

Troubleshooting 418

524204500-1800YRM1076-(03-2007)-UK-EN 423

toc 423

Brake System 423

Safety Precautions Maintenance and Repair 424

Introduction 427

General 427

Discharging the Capacitors 427

Brake Pedal Assembly 428

Remove 428

Disassemble 428

Assemble 429

Install 430

Master Cylinder 430

Remove 430

Install 431

Adjustments 432

Bleed the Brake System 432

Adjust Linkage 432

Brake Lines 433

Parking Brake 433

Remove 433

Install 434

Troubleshooting 434

524204501-1900YRM1077-(09-2013)-UK-EN 439

toc 439

Hydraulic System 439

Safety Precautions Maintenance and Repair 440

Introduction 443

General 443

Discharging the Capacitors 444

Hydraulic System 445

Hydraulic Oil 445

Hydraulic Lines 445

Cleaning 445

Sound Level 445

Maintenance 446

Hydraulic Oil Filter, Change 446

Hydraulic Oil Strainer, Check 446

Hydraulic Oil, Change 447

Hydraulic Tank Assembly 448

Remove 448

Clean 449

Trisodium Phosphate Method 449

Install 449

Lift Pump and Motor 450

Remove 450

Disassemble 451

Assemble 451

Install 452

Lift Pump 453

Disassemble 453

Assemble 453

524204502-2000YRM1085-(10-2006)-UK-EN 457

toc 457

HUSCO™ Main Control Valve 457

Safety Precautions Maintenance and Repair 458

General 461

Description 461

Operation 462

Lift Section 464

Tilt Section 464

Tilt Backward 464

Tilt Forward 465

Relief Valve 466

Main Control Valve Repair 467

Remove 467

Disassemble 467

Clean and Inspect 469

Assemble 469

Install 471

Switch Plate Adjustment 473

Pressure Relief Valve Check and Adjustment 474

Primary Relief Valve 474

Secondary Relief Valve 474

Troubleshooting 475

524204503-2000YRM1086-(06-2004)-UK-EN 479

toc 479

Electro-Hydraulic Control Valve 479

Safety Precautions Maintenance and Repair 480

General 483

Description 483

Electro-Hydraulic Control System 483

Electro-Hydraulic Control Valve 484

Valve Driver Module 487

Manual Lowering Valve 487

Hydraulic Lever Console 487

Electro-Hydraulic Control Valve 487

Remove 487

Disassemble 488

Clean and Inspect 488

Assemble 489

Lift Valve Section 489

Tilt/Auxiliary Valve Sections 489

Valve Spool Coils 490

Fittings 490

Install 490

Check and Adjust 491

Tilt Counterbalance Valve 491

Main Relief Valve 491

Auxiliary Relief Valve 491

Valve Driver Module 491

Remove 491

Install 491

Hydraulic Lever Console 492

Remove 492

Disassemble 492

Covers 492

Hydraulic Control Lever 492

Main PC Board 492

Assemble 493

Main PC Board 493

Hydraulic Control Lever 493

Covers 493

Install 493

Troubleshooting 494

Troubleshooting Chart 494

tables 479

Table 1 Error Codes 494

524204504-2200YRM1087-(09-2013)-UK-EN 501

toc 501

AC Motor Controllers/Display Panel 501

Safety Precautions Maintenance and Repair 502

Description 505

General 505

Description 505

AC Motors 505

ZAPI™ AC Motor Controller 505

Principles of Operation 506

Controller Thermal Management 507

Controller Area Network (CANbus) 507

Discharging the Capacitors 507

AC Motor Controller Repair 509

General 509

Special Precautions 509

Thermal Sensors 510

Motor Controller, Replace 510

Controller Checks and Adjustments 510

Function Parameters 511

General 511

Function Parameter Descriptions 512

Parameters 512

Top Speed Forward 512

Top Speed Reverse 512

Acceleration 512

Regen Braking 513

Auto Deceleration 513

Extended Shift 513

Pump Acceleration 513

Tilt/Auxiliary Pump Acceleration 513

Low Lift Speed 513

Maximum Lift Speed 513

Maximum Lowering Speed 513

Tilt Speed 513

3rd Function 514

3rd Function Speed 514

4th Function 514

4th Function Speed 514

Battery Voltage 514

Lift Interrupt 514

BDI Adjustment (Early Models) 514

BDI Adjustment (Later Models) 514

BDI Decrement Time 515

Service Reminder 515

Custom 515

Restore Defaults 515

Calibration Parameters 516

Throttle Calibration 516

Steering Calibration 516

Display Panel 516

General 516

Premium Display Panel 516

Standard Display Panel 516

Display Functions and Features 516

Key-On Initialization 516

Standard Display 519

Premium Display 519

Lift Truck Inspection Function 520

Access to Service Functions 520

Service Functions 521

Performance Modes 522

Battery Discharge Indicator (BDI) 522

Hourmeter 523

Status Code List 523

Dash Display Service Menu Navigation 524

General 524

Moving Through Menu Selections 524

Editing and Adding Information 524

ETACC Test 525

Manual Hydraulics 525

Electro-Hydraulics 525

Troubleshooting 525

General 525

Status Codes 526

Controller Connector Pin Outs 616

Valve Driver Module (Electro-Hydraulic Valve Option) 617

Hydraulic Lever Console (Electro-Hydraulic Option Only) 618

Dash Display 618

System Logic Diagrams 619

tables 501

Table 1 Traction Parameters 511

Table 2 Transistor Lift With Manual Valve Parameters 511

Table 3 Transistor Lift With Electro-Hydraulic Valve Parameters 512

Table 4 List of Status Codes 526

Table 5 Connector A 616

Table 6 Connector C 616

Table 7 Connector D – Standard Model 617

Table 8 Connector D – Premium Model 617

Table 9 Connector B 617

Table 10 Connector C 617

524204505-2200YRM1078-(07-2005)-UK-EN 625

toc 625

Electrical System 625

Safety Precautions Maintenance and Repair 626

Introduction 629

General 629

Discharging the Capacitors 629

Emissions 631

Electromagnetic Interference 631

Motor Controllers 631

Controllers 631

Remove 631

Install 632

Hydraulics Contactor 633

Remove 633

Disassemble 633

Assemble 633

Install 633

Contactor Panel 634

Main Contactor 634

Remove 634

Disassemble 635

Assemble 635

Install 635

Contactor Coil 636

Contactor Tips 636

Fuses 636

Display Units 637

Features 637

Replace 638

Key Switch 638

Replace 638

Directional Controls 640

Directional Control Switches 640

Accelerator Switches and Pedal Assembly 641

Install 641

Calibrate 644

Foot Directional Control 644

Brakes 646

Brake Switch 646

Adjust or Replace 646

Master Cylinder Indicator 646

Parking Brake Disengage 647

Override Mode 647

Horn Components and Steering Encoder 648

Horn Components 648

Horn 648

Horn Button and Contacts 649

Steering Encoder 649

Hood and Seat Switches 650

Hood Position Switches 650

Seat Switch 650

Steer Angle Potentiometer 651

General 651

Operation 651

Example 651

Position Steer Tire for Straight Travel 652

Install 652

Set Potentiometer to Midpoint 652

Install to Steer Axle 652

Calibrate 653

Test 654

Wiring Harness 654

tables 625

Table 1 Potentiometer Specifications 654

524204506-8000YRM1079-(06-2009)-UK-EN 661

toc 661

Periodic Maintenance 661

Safety Precautions Maintenance and Repair 662

Introduction 665

General 665

Discharging the Capacitors 665

How to Move Disabled Lift Truck 667

How to Tow Lift Truck 667

How to Put Lift Truck on Blocks 668

How to Raise Drive Tires 668

How to Raise Steer Tires 668

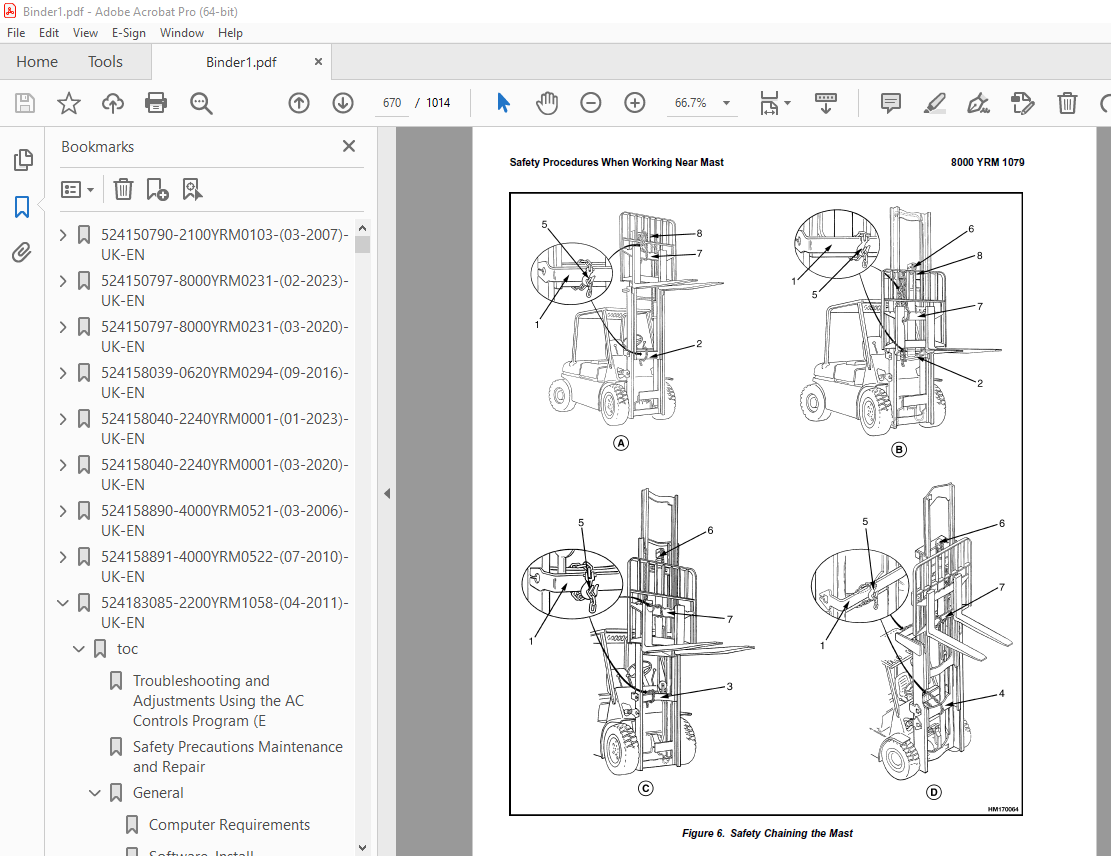

Safety Procedures When Working Near Mast 669

Maintenance Schedule 671

Maintenance Procedures Every 8 Hours or Daily 675

Checks With the Key Switch OFF 675

Safety Labels and Decals 675

Frame 675

Wheels and Tires 675

Mast, Carriage, and Forks 675

Hydraulic Oil Level and Leaks 676

Operator and Battery Restraints 677

Battery Check 678

Checks With the Key Switch ON 678

Electrical Components 678

Directional Speed Control 678

Steering System 678

Hydraulic System 679

Brakes 679

Maintenance Procedures Every 500 Hours or 3 Months 679

Tire and Wheel Assemblies 679

Mast and Carriage 680

Hydraulics 681

Battery 681

Hydraulic Motor Brushes 681

Parking Brakes 681

Transaxle 683

Maintenance Procedures Every 1000 Hours or 6 Months 683

Lift Chains 683

Integral Sideshift Carriage 684

Check Upper and Lower Bearings 684

Hydraulic Breather Cap 684

Master Cylinder 685

Electrical Inspection 685

Contactors 685

Directional Speed Control 685

Transaxle, Oil Change 686

Maintenance Procedures Every 2000 Hours or Yearly 687

Steering 687

Hydraulic 687

Hydraulic Oil Filter, Change 687

Hydraulic Oil Strainer, Check 688

Hydraulic Oil, Change 688

Integral Sideshift Carriage 688

Replace Upper and Lower Bearings 688

General Repairs 689

Welding Repairs 689

Painting Instructions 689

Lift and Tilt System Leak Check 690

Lift System 690

Tilt System 690

Battery Maintenance 691

How to Charge Battery 691

How to Change Battery 692

Battery Size Specifications 692

tables 661

Table 1 Maintenance Schedule 672

524204507-8000YRM1080-(03-2009)-UK-EN 695

toc 695

Capacities and Specifications 695

Safety Precautions Maintenance and Repair 696

General 699

Lubrication Specifications 700

Hydraulic System 700

Steering System 701

Tire Sizes 702

Torque Specifications 703

Electrical 703

Steering System 703

Hydraulic System 703

Manual Hydraulic Valve 703

Transaxle 704

Transaxle Assembly 704

Travel Speeds 705

Battery 706

524204508-8000YRM1081-(04-2007)-UK-EN 713

toc 713

Diagrams 713

Safety Precautions Maintenance and Repair 714

524214915-0620YRM1115-(06-2006)-UK-EN 747

toc 747

AC Traction Motor Repair 747

Safety Precautions Maintenance and Repair 748

Introduction 751

General 751

Discharging the Capacitors 751

Description 753

Traction Motor 753

AC Motor Repair 754

Remove 754

Disassemble 754

Inspect 754

Assemble 756

Install 756

Troubleshooting 757

524223768-2100YRM1139-(02-2014)-UK-EN 761

524223776-4000YRM1148-(09-2015)-UK-EN 809

General 813

Safety Procedures When Working Near Mast 814

Fork Replacement 816

Remove, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 816

Remove, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 818

Install, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 819

Install, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 819

Checks, Lift Trucks Not Equipped With Fork Positioner Or Equipped With Fork Positioner Before August, 2012 820

Checks, Lift Trucks Manufactured After August, 2012 And Equipped With Fork Positioner 821

Carriages Repair 822

Standard Carriage 822

Remove 822

Repair 823

Install 823

Standard Carriage, Remove 824

Hang-On Sideshift Carriage, Remove 825

Standard Carriage and Hang-On Sideshift Carriage, Repair 826

Standard Carriage, Install 827

Hang-On Sideshift Carriage, Install 827

Integral Sideshift Carriage 828

Remove 828

Clean and Inspect 831

Repair 832

Install 832

Fork Positioner 833

Remove 833

Clean and Inspect 838

Disassemble and Assemble 838

Install 838

Fork Positioner Hydraulic Hose Adjustment 839

Disconnecting Attachment Hydraulic Quick Disconnect Hoses 841

Connecting Attachment Hydraulic Quick Disconnect Hoses 841

Mast Repair 842

Mast, Remove 842

Two-Stage LFL and Two-Stage FFL Masts 845

Disassemble 845

Clean and Inspect 855

Three-Stage FFL Mast 856

Disassemble 856

Clean and Inspect 864

Two-Stage LFL and Two-Stage FFL Mast 866

Assemble 866

Three-Stage FFL Mast 869

Assemble 869

Four-Stage FFL Mast – Manufactured Before July, 2009 871

Disassemble 871

Clean and Inspect 876

Assemble 878

Four-Stage FFL Mast – Manufactured After July, 2009 879

Disassemble 879

Clean and Inspect 886

Assemble 889

Mast, Install 890

Header Hose Arrangement 893

Two-Stage LFL 893

Two-Stage FFL 901

Three-Stage FFL 916

Standard 916

Optional Equipment Lift Truck GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) 933

Four-Stage FFL Mast – Manufactured Before July, 2009 941

Four-Stage FFL Mast – Manufactured After July, 2009 950

Adjustment 957

Lift Chains Adjustment 957

Carriage Adjustments 960

Mast Adjustments 960

Load Roller Adjustment 960

Mast Side Kicking Adjustment 963

580061048-4000YRM1176-(09-2013)-UK-EN 967

toc 967

Four-Stage (Quad) Mast 967

Safety Precautions Maintenance and Repair 968

General 971

Description 971

Carriages 971

Mast Mounts 972

Mast 973

Operation 974

Safety Procedures When Working Near Mast 979

Forks 981

Remove 981

Install 981

Checks 981

Carriage 983

Remove 983

Inspect 984

Install 985

Main Lift Cylinders Repair 986

Remove 986

Repair 986

Install 987

Free-Lift Cylinder Repair 988

Remove 988

Repair 988

Install 989

Lowering Control Valve 990

Valve Cartridge Service 990

Mast, Complete 991

Remove 991

Install 991

Mast Repair 993

Disassemble 993

Clean and Inspect 997

Assemble 999

Load rollers 1001

Reach Assembly 1001

Load Rollers and Wear Plugs 1001

Thrust Rollers 1001

Header Hose Arrangements 1002

Crosshead Assembly 1004

Lift Chains 1004

Inspect 1004

Clean and Lubricate 1004

Adjustments 1005

Mast Adjustments 1006

Skewing 1006

Shimming 1007

Carriage Adjustments 1007

Tilt Cylinders Adjustment 1008

Lift and Tilt System Leaks Check 1009

Lift Cylinders Leaks Check 1009

Tilt Cylinders Leaks Check 1009

Troubleshooting 1010

tables 967

Table 1 Fork Tip Alignment Specifications 982