$45.95

Yale Forklift F876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual - PD

Yale Forklift F876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift F876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1092

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift F876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

524150779 1400YRM0046 (08 2012) US EN 1

toc 1

Differential 1

Safety Precautions Maintenance and Repair 2

General 5

Description 5

Differential Repair 5

Remove 5

Differential Carrier From Axle Housing, Remove 5

Differential and Ring Gear From Differential Carrier, Remove 9

Drive Pinion and Pinion Carrier From Differential Carrier, Remov 11

Disassemble 12

Differential and Ring Gear Assembly, Disassemble 12

Drive Pinion and Pinion Carrier, Disassemble 13

Clean and Inspect 16

Assemble 17

Pinion, Bearings, and Pinion Carrier, Assemble 17

Pinion Bearings, Adjust Preload 17

Press Method 17

Yoke or Flange Method 18

Triple-Lip Seal, Install 19

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion) 20

Differential and Ring Gear, Assemble 22

Differential Gears Rotating Torque, Check 24

Differential and Ring Gear Assembly, Install 25

Differential Bearings, Preload Adjust 26

Ring Gear, Runout Check 27

Ring Gear Backlash, Adjust 28

Gear Set, Tooth Contact Pattern Check 30

Thrust Screw, Install and Adjust 33

Install 33

Differential Assembly Into Axle Housing, Install 33

Specifications 34

Troubleshooting 38

tables 1

Table 1 Ring Gear Backlash Adjustment Specifications 29

Table 2 Ring and Pinion Tooth Contact Adjustment 30

Table 3 General Specifications 34

Table 4 Rivet Installation Pressure 34

Table 5 Pinion Adjustment 34

Table 6 Pinion Preload Pressure 35

Table 7 Torque Specifications 36

Table 8 Torque Specifications for Metric Hardware 37

Table 9 Torque Specifications for Metric (Fine) Hardware 37

524150780 1400YRM0944 (08 2012) US EN 41

toc 41

Planetary Drive Axle 41

Safety Precautions Maintenance and Repair 42

General 45

Description 45

Operation 47

Identification 47

Removal 48

Disassembly 48

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 49

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 50

Wheel End 52

Spindle and Piston Housing 53

Cleaning 54

Clean Ground or Polished Parts 54

Clean Parts With Rough Finish 54

Clean Axle Assemblies 54

Drying Cleaned Parts 54

Corrosion Prevention 54

Parts Inspection 55

Tapered Roller Bearings 55

Bevel Pinion and Ring Gear Sets 56

Main Differential Assembly 56

Axle Shafts 56

Yoke 56

Brakes 56

Repair or Replace Parts 56

Repair Welding 57

Apply Silicone Gasket Material 57

Assembly 57

Spindle and Piston Housing to Axle Housing 57

Wet Disc Brakes 58

Adjust Wheel Bearing Preload 59

Planetary Spider and Gearing Assembly GDP80-120DB (GP170-280DB) 60

Planetary Spider and Gearing Assembly GDP130-160EB (GP300-360EB) 60

Planetary Spider Assembly 61

Installation 62

Fill Wet Disc Brakes With Hydraulic Fluid 62

Torque Specifications 63

Lubrication Specification 64

524150797 8000YRM0231 (02 2023) US EN 67

General 73

Threaded Fasteners 73

Nomenclature, Threads 73

Strength Identification 74

Cotter (Split) Pins 75

Fastener Torque Tables 80

Conversion Table 82

524150797 8000YRM0231 (03 2020) US EN 89

General 93

Threaded Fasteners 93

Nomenclature, Threads 93

Strength Identification 94

Cotter (Split) Pins 95

Fastener Torque Tables 100

Conversion Table 102

524211827 0600YRM1101 (11 2018) US EN 109

Series Code / Model Designation Reference Table 113

General 113

Fault Codes 114

Normal Mode 114

Fault Log Mode 115

Access 115

Exit 115

Clear 115

Electronic Throttle Calibration 115

Electronic Throttle Calibration Procedure 116

Stationary Regeneration Procedure 116

524230692 8000YRM1181 (01 2017) US EN 145

Series Code / Model Designation Reference Table 149

General 150

Weight and Dimensions 150

Loading Procedures 158

Loading A Truck on a Transport 158

Loading Disassembled Components 158

Unloading Procedures 159

Unloading Complete Truck or Basic Truck From Transport 159

Lifting 159

Driving On/Off a Trailer 160

Unloading Disassembled Components 160

Removal of Forks Attached to Basic Truck 160

Removal of Forks Attached to the Carriage 160

Truck Assembly 161

Safety procedures When Working Near the Mast 162

Mast Installation 163

Preparations 163

Adjusting the Tilt Cylinders 165

Connecting the Lift Cylinders 165

Connecting the Mast Supply Hoses 166

Carriage and Forks 167

Installing the Carriage 167

Connecting the Header Hoses to the Carriage 167

Install the Forks 167

Installing Pin-Type Forks 167

Installing Quick Disconnect DFSSFP Forks 169

170

Installing Integrated DFSSFP Forks 170

Adjusting the Carriage 170

Adjusting Header Hose Tension 171

Adjusting the Electrical Cable Tension 172

Installing the Cab Lights 172

Adding the Mast Labels 173

Lubrication Points 173

Pre-Delivery Inspection 174

Empty Seat Engine Shut Down 174

Pre-Delivery Inspection 174

Pneumatic Tires and Wheels 175

Remove Wheels From Lift Truck 175

Remove Tire From Wheel 176

Install Tire on the Wheel 178

Adding Air Pressure to the Tires 180

Solid Rubber Tires, Remove Tire From the Wheel 180

Solid Rubber Tires, Install Tire on the Wheel 182

Install Wheels on Lift Truck 184

Moving and Towing 185

Moving a Disabled Lift Truck 185

Precautions 185

Towing A Lift Truck 186

550033398 0100YRM1459 (12 2018) US EN 189

Series Code / Model Designation Reference Table 193

Description and Operation 193

Heater System 193

General 193

Air Conditioning 194

General 194

Dryer 195

Compressor Lubrication 196

Control Systems, Sensors, and Switches 196

Climate Control 197

Description 197

Service Menu 197

Set Up 198

View 1 and View 2 198

Error List 199

Statistics 199

Exit 199

Temperature Sensors 199

Troubleshooting 199

Water Valve 200

Troubleshooting 200

Remove and Replace 202

Standard Heater Assembly 203

Access 203

Remove 203

Install 204

Standard Heater Parts 205

Heater Core 205

Remove 205

Install 206

Blower 206

Remove 206

Install 207

Water Valve 208

Remove 208

Install 208

Push/Pull Cable 209

Water Valve Cable 209

Remove 209

Install 209

Heater/Air Conditioner Assembly 210

Remove 210

Install 211

Heater/Air Conditioner Parts 211

Vent Door 211

Remove 211

Install 212

Heater Core 212

Remove 212

Install 213

Evaporator Core 214

Remove 214

Install 215

Blower 216

Remove 216

Install 216

Thermostat 217

Remove 217

Install 218

Water Valve 218

Remove 218

Install 219

Air Conditioning Technical Detail 220

550033400 0100YRM1390 (12 2018) US EN 223

Series Code / Model Designation Reference Table 231

General 231

Description of Operation 233

Cab Structure 233

Cab Tilt System 233

Cab Tip-Up System 235

Tilting the Cab 236

Raising 236

Lowering 237

Remove and Install 238

Cab Door Assembly 238

Cab Door 238

Remove 238

Install 238

Door Hinge 239

Remove 239

Install 239

Door Latch 240

Remove 240

Install 240

Door Handle 240

Remove 240

Install 240

Door Release 241

Remove 241

Install 241

Door Push Button 241

Remove 241

Install 242

Cab Tilt System 242

Electric Tilt Pump 242

Remove 242

Install 242

Hand Tilt Pump 242

Remove 242

Install 243

Cab Tilt Cylinder 244

Remove 244

Disassemble 244

Clean 246

Inspect 246

Assemble 246

Install 247

Latch 247

Remove 247

Install 248

Brake and Inching Pedal 249

Remove 249

Install 249

Accelerator Pedal and Sensor 250

Remove 250

Install 250

Adjust Sensor 250

Seat Assembly 250

Seat 250

Remove 250

Install 251

Seat Cushion 251

Remove 251

Install 252

Back Cushion 252

Remove 252

Install 252

Seat Suspension Replacement 252

Boot Replacement 252

Power Assist Armrest 276

Release Cable 276

Remove 276

Install 276

Gas Spring 276

Remove 276

Install 277

Joystick 277

Remove 277

Install 277

Electrical Levers 277

Remove 277

Install 278

Armrest Rocker Switches 278

Remove 278

Install 278

Armrest Top Cover 278

Remove 278

Install 278

Instrument Panel 279

Key Switch 279

Remove 279

Install 279

12V Power Socket 279

Remove 279

Install 279

Electric-Operated Heat Control and Air Recirculation Control (Airco Only) 280

Remove 280

Install 280

Cable-Operated Heater Control (Heater Only) 281

Remove 281

Install 281

Air Conditioning Switch Replacement 281

Instrument Panel Rocker Switches Replacement 281

Parking Brake Switch 282

Remove 282

Install 282

Indicator Display Replacement 282

Instrument Panel Top Console 282

Remove 282

Install 283

Steering Wheel and Column Assembly 283

Steering Wheel and Horn 283

Remove 283

Install 285

Steering Column Assembly 285

Remove 285

Install 286

Adjustment Handle 286

Remove 286

Install 286

Main Warning Lights 287

Remove 287

Install 287

Shift Lever 287

Remove 287

Install 287

Turn Signal Lever 287

Remove 287

Install 287

Window Wipers 288

Window Wiper Assembly Replacement 288

Remove 288

Install 288

Window Wiper Motor Replacement 288

Front Window Wiper Motor 288

Install 288

Rear Window Wiper Motor Assembly 289

Remove 289

Install 289

Top Window Wiper Motor Assembly 289

Remove 289

Install 289

Window Washer System 290

Window Washer Reservoir and Pumps 290

Remove 290

Install 290

Window Washer Hoses 291

Hoses for Top and Rear Window 291

Install 292

Window Washer Spray Nozzles 292

Front Window 292

Remove 292

Install 292

Rear Window 293

Remove 293

Install 293

Top Window 293

Remove 293

Install 293

Window Replacement 293

Front Window 295

Remove 295

Install 295

Rear Window 295

Remove 295

Install 295

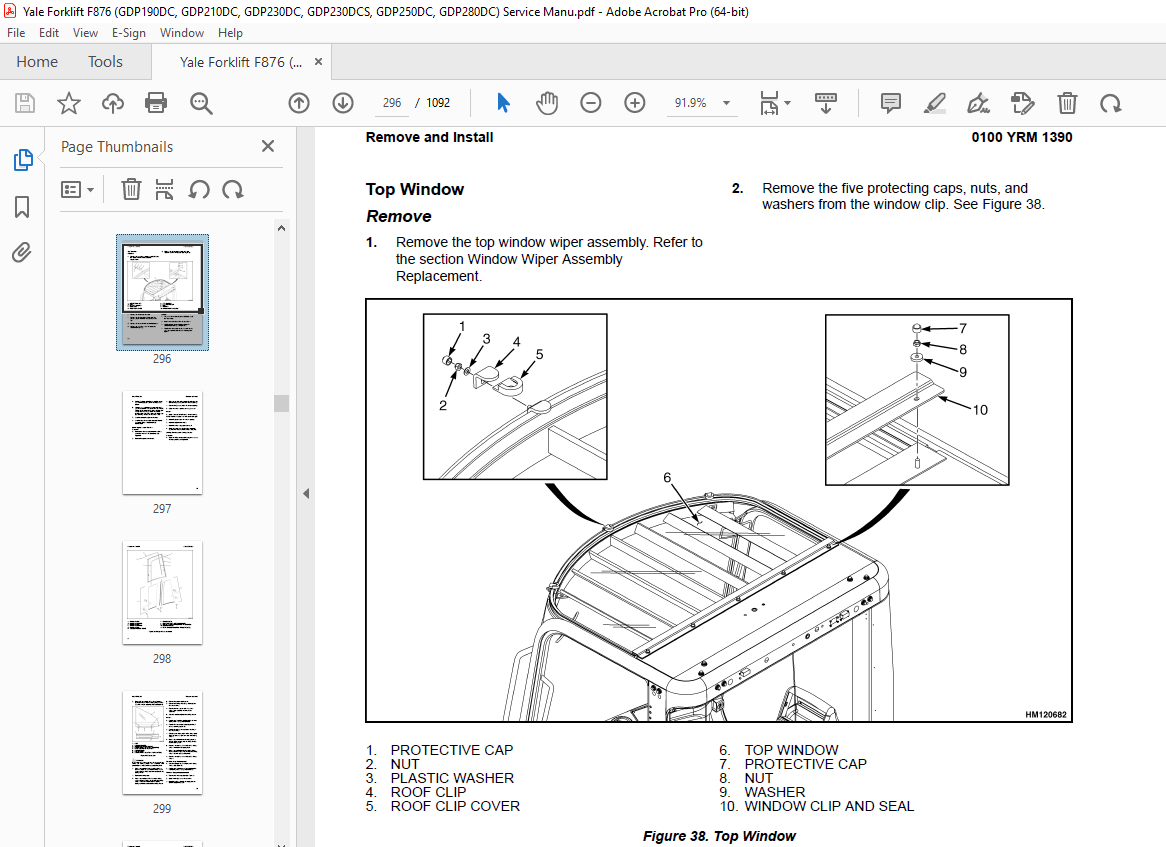

Top Window 296

Remove 296

Install 296

Door, Upper/Lower Window 297

Remove 297

Install 297

Sliding Window and Sliding Tracks 297

Remove 297

Install 299

Weather Strip Replacement 299

Window Stopper Replacement 299

Window Seal Replacement 300

Sliding Window Frame 300

Remove 300

Install 300

Floor Mat 300

Front Floor Mat 300

Remove 300

Install 301

Rear Floor Mat 301

Remove 301

Install 302

Radio Console 302

Remove 302

Install 302

Air Duct Replacement 303

Remove Front 303

Remove Rear 303

Install 304

Accessories 304

Mirror Replacement 304

Sunshade Replacement 304

Top 304

Rear 305

Map Light Replacement 305

Interior Fan Replacement 305

Training Seat 305

Field Installation 305

Remove 305

Label Replacement 306

Checks and Adjustments 306

Check Oil Level for Cab Tilt System 306

Door Striker Pin Adjustment 307

Brake Pedal Adjustment 307

Dry Brake 307

Wet Brake 308

Inching Pedal Adjustment 308

Inching Pedal Sensor Adjustment 308

Sensor Adjustment Using Dana Dashboard Software 308

Sensor Adjustment using the APC200 Display 309

Sensor Adjustment for Trucks with ZF Transmission 310

Inching Pedal Sensor Calibration 310

Sensor Calibration using Dana Dashboard Software 310

Sensor Calibration using APC200 Display 310

Sensor Calibration for Trucks with ZF Transmission 311

550035498 2200YRM1481 (08 2012) US EN 315

toc 315

Hydraulic Control System 315

Safety Precautions Maintenance and Repair 316

General 319

Description 319

Control Valve 319

Analog Inputs 320

Levers and Joysticks 320

Sensors 321

Temperature Sensor 321

Pressure Sensor 321

Digital Inputs 321

Switches 321

Interrupts 321

CAN Bus Communication 322

Output Signals 322

Analog Outputs 322

Digital Outputs 322

Programmed Features 322

Anti-Stall (Standard) 322

Temperature Protection (Standard) 322

Low Temperature Protection (Standard) 323

High Temperature Protection (Optional) 323

Dynamic Control (Optional) 323

Loaded Speed Reduction (Optional) 323

Settings 323

Adjustable Parameters 323

Truck Configuration Screen 323

Mode Definition Responsiveness (Smooth, Medium, and Rapid) 323

Set Default Flow Settings Screen 323

Features Screen 323

Loaded Speed Reduction Screen 323

Flow Settings Screen 324

General Functions of the Interface 324

Main Functional Requirements 324

What is Needed for the Hydraulic User Interface Program 324

Installation of the Program 324

Start Screen 327

Reminder Screen 328

Basic Screen Layout of the Hydraulic User Interface Program 329

Truck Configuration Screen 330

Mode Definition Screen 332

Default Flow Settings Screen 333

Load Moment Interrupt Screen 334

Features Screen 335

Dynamic Control Screen 336

Loaded Speed Reduction Screen 337

Temperature Protection Screen 338

Anti-Stall Screen 339

Calibration Screen 340

Calibrating the Connected Levers/Joystick Without the Interface 340

Calibrating the Connected Levers/Joystick With the Interface Sof 340

Profile Configuration Screen 341

Flow Settings Screen 342

Valve Settings Screen 343

Diagnostic Screen 344

Active Errors Screen 345

Error History Screen 346

All Parameters Screen 347

Installing the Hydraulic Controller Software and Read-Only Param 348

Calibration 351

Calibrating the Lever With the Hydraulic User Interface Program 351

Calibrating the Joystick With the Hydraulic User Interface Progr 351

Calibrating the Lever Without the Hydraulic User Interface Progr 351

Calibrating the Joystick Without the Hydraulic User Interface Pr 351

Fault Codes 352

Controller Pinning 362

tables 315

Table 1 Temperature and Maximum Engine Speed 323

Table 2 Hydraulic User Interface Program Overview 325

Table 3 Parameters 332

Table 4 Temperature/Rpm Table 338

Table 5 Fault Codes 352

Table 6 Fixed PT 362

Table 7 Alternating PT 364

Table 8 Empty Container Handler (ECH) 366

Table 9 XML Parameter File Content 367

550035502 1300YRM1455 (11 2018) US EN 373

Series Code / Model Designation Reference Table 377

General 377

Description 377

General 377

Clutch 382

Operation 382

Hydraulic Operation 382

Clutch Valve 383

Cooling and Lubrication 384

Control System 385

Transmission Control Unit (TCU) 386

Operating Modes 386

Normal Mode 386

Substitute Clutch Control 386

Limp-Home Mode 386

Transmission Shut Down Mode 386

TCU Shut Down Mode 386

Transmission Exceed Codes 386

Self-Test 387

Fault Codes 387

Description 387

Fault Log Mode 387

Access 387

Exit 388

Clear 388

Fault Log Memory 388

Fault Rectification 388

Hydraulic Control Valve 389

Hydraulic Control Valve Repair 390

Solenoid Replacement 390

Pressure Check 390

Pressure Specifications 391

Speed and Temperature Sensors 391

Speed Sensors 392

Test 393

Temperature Sensors 393

Shift Lever 393

PedalFoot Directional Control 393

ZF Transmission Test and Calibration 394

Transmission Test and Calibration 394

Precautions 394

Stall Test 394

Description 394

Stall Test Procedure 394

Inch Pedal Calibration 395

Description 395

Calibration 395

Brake and Inch Pedal Adjustment 395

Inch Sensor Adjustment 395

Inch Pedal Calibration 396

Preparation 396

Calibration Procedure Using the Calibration Switch 396

Calibration Procedure Using the Testman software 396

Inch Pedal Calibration Fault Codes 396

Clutch Calibration 397

Description 397

Clutch Calibration Procedure 398

Manual Clutch Calibration Procedure 398

Testman Clutch Calibration Procedure 399

Testman 399

Description 399

Connection 400

Truck Configuration 400

Configuration 400

Limitations 400

Capacities and Specifications 401

Electrical Specifications 401

Transmission Control Unit Diagram 401

ZF Transmission Fault Codes 403

Transmission Exceed Codes 403

Testman Fault Codes 404

550035503 1300YRM1456 (12 2015) US EN 415

Series Code / Model Designation Reference Table 419

Special Tools List 420

Transmission Repair 421

Remove 421

Disassemble 425

Clean and Inspect 464

Housings 465

Oil Seals and Gaskets 465

Bearings 465

Gears and Shafts 465

Assemble 466

Transmission Oil Filter Assembly Replacement 513

Clean 514

Inspect 514

Install 515

Control Valve Replacement 520

Remove 520

Install 521

Control Valve Repair 522

Disassemble 522

Clean 526

Inspect 526

Assemble 527

550035504 1600YRM1479 (08 2012) US EN 535

toc 535

Steering System 535

Safety Precautions Maintenance and Repair 536

General 541

Basic Principles of Flow Control Systems 541

Basic Principles of Flow Control Systems 541

Orifice (Fixed/Variable) 541

Basic Principle 541

Pressure Compensated Flow Control Valve 542

Basic Principle 542

Pressure Compensated Flow Control Valve Functional Description 542

Priority Valve 542

Basic Principle 542

Priority Valve Functional Description 543

Load Sense (LS) 544

Basic Principle 544

Load Sense Functional Description 544

Example 1 545

Example 2 545

Basic Principles of Pressure Control Systems 545

Basic Principles of Pressure Control Systems 545

Direct Acting Relief Valves 546

Basic Principle 546

Direct Acting Relief Valve Functional Description 546

Two-Stage Relief Valve (Pilot Operated Relief Valve) 546

Basic Principle 546

Two-Stage Relief Valve (Pilot Operated Relief Valve) Functional 546

Unloading Valve (Accumulator Charging Valve) 547

Basic Principle 547

Unloading Valve (Accumulator Charging Valve) Functional Descript 547

Counterbalance Valve 548

Basic Principle 548

Counterbalance Valve Functional Description 549

Pressure Reducer Valve 549

Basic Principle 549

Pressure Reducer Valve Functional Description 549

Steering System Main Component Identification 550

Description and Operation 553

Steering System 553

Introduction 553

Description 553

Hydraulic Oil Flow Path 553

Priority Valve 553

Fundamentals 553

Description 553

Operation 553

Component Validation for Correct Operation 554

Steering Control Unit 554

Description 554

Steering Control Valve 554

Fundamentals 554

Operation 554

Component Validation for Correct Operation 554

Hand Pump 555

Fundamentals 555

Operation 555

Component Validation for Correct Operation 555

LS Relief Valve 555

Fundamental 555

Operation 555

Component Validation for Correct Operation 555

Shock Valve 555

Fundamental 555

Operation 555

Component Validation for Correct Operation 555

Steering Axle 555

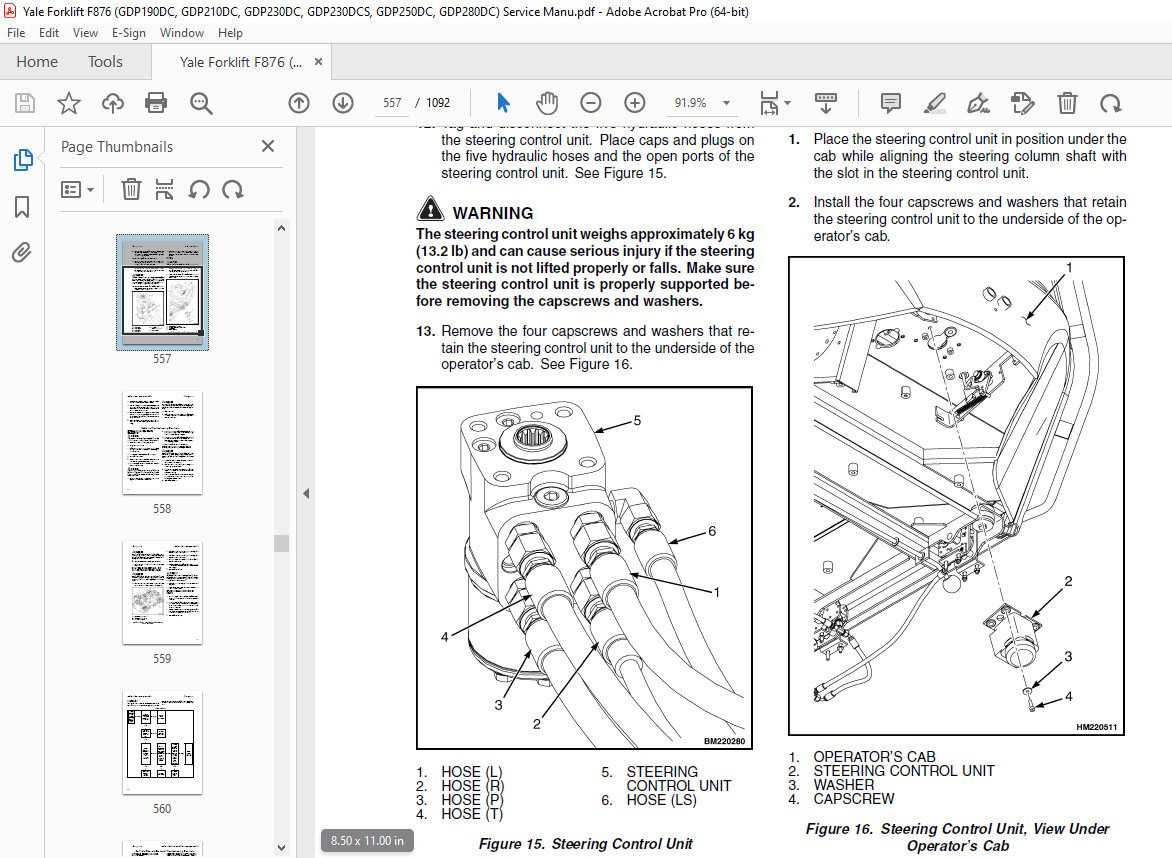

Steering Control Unit 556

Remove 556

Install 557

Hydraulic Troubleshooting Flowcharts 558

Hydraulic Pressure Checks Preparation 558

Steering Relief Pressure Check 558

Pressure Check, Port MLS1 and MLS2 on the Main Control Valve 559

Steering Wheel Lock to Lock Check 559

Flowchart 560

Hydraulic Pressure Checks for Troubleshooting Flowcharts 561

Hydraulic Pressure Checks Preparation 561

Condition Check, Shuttle Valve L and M in the Main Control Valve 561

Condition Check, Logic Element N in the Main Control Valve 562

Condition Check, Priority Valve on the Main Control Valve 562

Steering Cylinder 562

Remove and Disassemble 562

Clean and Inspect 564

Assemble and Install 564

Steering Axle Assembly 566

Steer Axle 566

Remove 566

Install 566

Wheels and Hubs 568

Remove and Disassemble 568

Clean 568

Inspect 568

Assemble and Install 568

Spindles and Bearings 569

Remove 569

Clean 570

Assemble and Install 570

Tie Rods 570

Remove 570

Clean 570

Install 570

Torque Specifications 572

Steering Control Unit 572

Steering Axle 572

Wheel Nuts 572

Steering Cylinder 572

tables 535

Table 1 Definition of Terms 541

Table 2 Definition of Terms 545

Table 3 Internal Components of the Steering Control Unit 554

Table 4 Flowchart 560

550035505 1800YRM1498 (03 2013) US EN 575

toc 575

Brake and Hydraulic Cooling System 575

Safety Precautions Maintenance and Repair 576

General 583

Basic Principles of Flow Control Systems 583

Basic Principles of Flow Control Systems 583

Orifice (Fixed/Variable) 584

Basic Principle 584

Pressure Compensated Flow Control Valve 584

Basic Principle 584

Pressure Compensated Flow Control Valve Functional Description 584

Priority Valve 585

Basic Principle 585

Priority Valve Functional Description 585

Load Sense (LS) 586

Basic Principle 586

Load Sense Functional Description 586

Example 1 587

Example 2 587

Basic Principles of Pressure Control Systems 587

Basic Principles of Pressure Control Systems 587

Direct Acting Relief Valves 588

Basic Principle 588

Direct Acting Relief Valve Functional Description 588

Two-Stage Relief Valve (Pilot-Operated Relief Valve) 589

Basic Principle 589

Two-Stage Relief Valve (Pilot Operated Relief Valve) Functional 589

Unloading Valve (Accumulator Charging Valve) 590

Basic Principle 590

Unloading Valve (Accumulator Charging Valve) Functional Descript 590

Counterbalance Valve 591

Basic Principle 591

Counterbalance Valve Functional Description 591

Pressure Reducer Valve 592

Basic Principle 592

Pressure Reducer Valve Functional Description 592

Brake System Main Component Identification 592

Description 598

Brake Pressure System 598

Main System 598

Introduction 598

Service Brakes 598

Park Brake 598

Description 598

Hydraulic Oil Flow Path 598

Brake Accumulator Charging System 598

Service Brake System 599

Park Brake System 599

Priority Valve 599

Fundamentals 599

Description 599

Operation 599

Component Validation for Correct Operation 599

Brake Control Manifold 599

Description 599

Orifice (F) 600

Fundamentals 600

Description 600

Operation 600

Component Validation for Correct Operation 601

Unloading Valve 601

Fundamentals 601

Operation 601

Component Validation for Correct Operation 601

Screen 601

Description 601

Component Validation for Correct Operation 601

Check Valve 601

Description 601

Component Validation for Correct Operation 601

Pressure Reducer Valve 601

Fundamentals 601

Operation 601

Component Validation for Correct Operation 601

Park Brake Selector Valve 601

Fundamentals 601

Operation 601

Component Validation for Correct Operation 601

Brake Accumulator 602

Fundamentals 602

Operation 602

Component Validation for Correct Operation 602

Brake Treadle Valve 602

Fundamentals 602

Description 602

Operation 602

Wet Disc Brake Cooling System 602

Main System 602

Introduction 602

Description 602

Hydraulic Oil Flow Path 602

Gear Pump 603

Fundamentals 603

Operation 603

Brake Cooling Valve 603

Description 603

Operation 603

Thermostatic Bypass Valve 603

Fundamental 603

Operation 603

Component Validation for Correct Operation 603

Brake Flow Distribution Manifold 603

Fundamentals 603

Operation 603

Component Validation for Correct Operation 604

Hydraulic Oil Cooler Core 604

Fundamentals 604

Operation 604

Brake Return Line Filter ( E876 & E877 Only) 605

Operation 605

Cooling System Air Brakes 605

Main System 605

Description 605

Hydraulic Oil Flow Path 605

Component Explanation 605

Brake Treadle Valve Repair 606

Remove 606

Install 606

Accumulator 607

Remove 607

Disassemble 608

Clean 609

Inspect 609

Repair 610

Assemble 610

Install 610

Pre-Charge Filling 611

Parking Brake 612

Parking Brake Caliper 612

Remove 612

Disassemble 613

Clean and Inspect 613

Assemble 615

Install 615

Parking Brake Caliper Pads 615

Remove 615

Install 616

Parking Brake Bleed 616

Parking Brake Emergency Release 617

Brake Flow Distribution Manifold 617

Remove 617

Pressure Relief Valve 619

Disassemble 619

Clean and Inspect 619

Assemble 619

Install 619

Brake Control Manifold 620

Remove 620

Orifices F and G 621

Disassemble 621

Assemble 621

Orifice H 621

Disassemble 621

Assemble 621

Unloading Valve (B) 621

Disassemble 621

Assemble 621

Screen 621

Disassemble 621

Assemble 621

Check Valve (E) 622

Disassemble 622

Assemble 622

Pressure Reducer Valve (C) 622

Disassemble 622

Assemble 622

Park Brake Selector Valve (A) 623

Disassemble 623

Assemble 623

Install 623

Brake Cooling Valve 624

Remove 624

Install 624

Filter Restriction Indicator (Optional) 625

Remove 625

Install 625

Filter 626

Remove 626

Install 626

Brake Return Line Filter ( E876 & E877 Only) 627

Brake Return Line Filter Assembly 627

Remove 627

Install 628

Filter 628

Remove 628

Install 628

Gear Pump 628

Remove 628

Disassemble 628

Clean 630

Inspect 630

Assemble 631

Install 631

Hydraulic Troubleshooting Flowcharts 632

Mechanical Troubleshooting 636

Checks and Adjustments 638

Hydraulic Pressure Checks Preparation 638

Park Brake Selector Valve Check 638

Park Brake Selector Valve Coil Check 638

Accumulator Pre-Charge Check 638

Parking Brake Adjustment 639

Condition Check, Shuttle Valve L in the Main Control Valve 640

Condition Check, Shuttle Valve N in the Main Control Valve 640

Condition Check, Priority Valve on the Main Control Valve 640

Pressure Check, Port MLS1 641

Torque Specifications 641

Hydraulic Hose Torque Specifications 641

tables 575

Table 1 Definition of Terms 583

Table 2 Definition of Terms 587

Table 3 Internal Components of the Brake Control Manifold 600

Table 4 Internal Components of the Brake Cooling Valve 604

Table 5 Low Brake Pressure Warning Is Intermittent or Constantl 633

Table 6 Service Brake Is Soft or Spongy 634

Table 7 Hydraulic Oil is Overheating 635

Table 8 Parking Brake Will Not Disengage With the Parking Brake 635

Table 9 Lining-to-Disc Clearance 640

550035506 1900YRM1478 (11 2018) US EN 645

Series Code / Model Designation Reference Table 653

Fundamentals 653

Basic Principles of Flow Control Systems 653

Orifice (Fixed/Variable) 653

Basic Principle 653

Pressure Compensated Flow Control Valve 654

Basic Principle 654

Pressure Compensated Flow Control Valve Functional Description 655

Priority Valve 655

Basic Principle 655

Priority Valve Functional Description 655

Load Sense (LS) 656

Basic Principle 656

Load Sense Functional Description 657

Example 1 657

Example 2 657

Basic Principles of Pressure Control Systems 657

Direct Acting Relief Valves 658

Basic Principle 658

Direct Acting Relief Valve Functional Description 658

Two-Stage Relief Valve (Pilot-Operated Relief Valve) 658

Basic Principle 658

Two-Stage Relief Valve (Pilot-Operated Relief Valve) Functional Description 659

Pilot-Operated Selector Valves 659

Fundamentals 659

Function Description 660

Pump Pressure Free Flow Side 660

Function Pressure Blocked Flow Side 660

Unloading Valve (Accumulator Charging Valve) 661

Basic Principle 661

Unloading Valve (Accumulator Charging Valve) Functional Description 661

Counterbalance Valve 662

Basic Principle 662

Counterbalance Valve Functional Description 662

Pressure Reducer Valve 663

Basic Principle 663

Pressure Reducer Valve Functional Description 663

Description and Operation 663

Component Location and Identification 664

Main Control Valve 670

Introduction 670

Flow Path 670

Main Manifold 670

Introduction 670

Priority Valve (A) 670

Fundamentals 670

Description 671

Operation 671

Component Functionality Test 671

Check Valve (I) 671

Function Description 671

Function Operation 671

Component Functionality Test 671

Pilot Supply Circuit 671

Function Description 671

Pilot Supply Valve (F) 671

Fundamentals 671

Function Description 671

Function Operation 671

Component Functionality Test 671

Lift Pressure Selector Valve (B) 672

Function Description 672

Function Operation 672

Component Functionality Test 672

Check Valve (K) 672

Function Description 672

Component Functionality Test 672

Check Valve (Q) 672

Function Description 672

Component Functionality Test 672

Screen (O) 672

Function Description 672

Component Functionality Test 672

Relief Valve 672

Function Description 672

Load Sense Relief Valve (H) 672

Fundamentals 672

Functional Operation 672

Component Functionality Test 672

Pressure Controller on Pump 673

Fundamentals 673

Functional Operation 673

Component Functionality Test 673

Full Flow Relief Valve (C) and (G) 673

Fundamentals 673

Functional Operation 673

Component Functionality Test 673

Shuttle Valve (L) and (M) 673

Function Description 673

Component Functionality Test 673

Logic Valve (N) 674

Function Description 674

Function Operation 674

Load Sense Selector Valve (D) 674

Function Description 674

Component Functionality Test 674

Directional Control Valve Section 674

Functional Operation (System Level) 674

Directional Control Valve 675

Fundamentals 675

Description 675

Functional Operation 675

Electrical Actuation Module (Solenoid End Cap) 675

Functional Operation 675

Component Functionality Test 676

Lift Function 676

Function Description 676

Pilot-Operated Check Valve 676

Fundamentals 676

Function Description 677

Function Operation 677

Emergency Lowering Valve (LH Lift Section ONLY) 677

Function Description 677

Lowering Control Valve 677

Fundamentals 677

Function Description 677

Tilt Function 677

Function Description 677

Impact Relief Valve 678

Fundamentals 678

Function Description 678

Counterbalance Valve 678

Fundamentals 678

Function Description 678

Auxiliary Function 678

Function Description 678

Carriage Valve Bank 678

Introduction 678

Functional Operation 679

Inlet Module 679

Directional Control Valve Section 679

Directional Control Valve 679

Electrical Actuation Module (Solenoid End Cap) 680

Variable Displacement Pump 680

Function Description 680

Basic Functional Operation 681

Pressure Control Valve 681

Fundamentals 681

Operation 681

Load Sense Pressure Regulator 681

Fundamentals 681

Functional Operation 681

Repair 682

Main Control Valve 682

Remove 682

Clean 687

Inspect 687

Assemble 687

Install 687

Priority Valve (A) 690

Remove 690

Clean 690

Inspect 691

Component Functionality Test 691

Install 691

Check Valve (K) 691

Remove 691

Clean 691

Inspect 691

Component Functionality Test 691

Install 691

Check Valve (I) 691

Remove 691

Clean 691

Inspect 692

Component Functionality Test 692

Install 692

Check Valve (Q) 692

Remove 692

Clean 692

Inspect 692

Component Functionality Test 692

Install 692

Screen Cartridge (O) 692

Disassemble 692

Component Functionality Test 692

Assemble 692

Shuttle Valves (L) and (M) 693

Remove 693

Clean 693

Inspect 693

Component Functionality Test 693

Install 693

Logic Valve (N) 694

Remove 694

Clean 694

Inspect 694

Component Functionality Test 694

Install 694

Full Flow Relief Valve ©) (Relief Spool) 694

Remove 694

Clean 694

Inspect 695

Assemble 695

Install 695

Pilot Supply Valve (F) 695

Remove 695

Clean 695

Inspect 695

Assemble 695

Component Functionality Test 695

Install 695

Load Sense (LS) Relief Valve (H) and Full Flow Relief Valve (G) 695

Remove 695

Clean 695

Inspect 696

Component Functionality Test 696

Install 696

Load Sense Relief Valve (H) Adjustment 696

Full Flow Relief Valve (G) Adjustment 696

Load Sense Selector Valve (D) 696

Remove 696

Clean 696

Inspect 697

Assemble 697

Install 697

Lift Pressure Selector Valve (B) 697

Remove 697

Clean 697

Inspect 698

Assemble 698

Install 698

Variable Displacement Pump (Primary and Secondary) 698

Remove 698

Clean 700

Inspect 700

Assemble 700

Install 701

Tilt Cylinder 702

Remove 702

Disassemble 702

Clean 702

Assemble 702

Install 703

Tilt Cylinder Leak Check 703

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment 704

Counterbalance Valves 704

Remove 704

Clean 705

Inspect 705

Assemble 705

Install 705

Carriage Valve Bank 705

Remove 705

Clean 708

Inspect 709

Assemble 709

Install 709

Electrical Actuation Module 709

Remove 709

Clean 709

Inspect 709

Assemble 709

Install 710

Emergency Lowering Valve (Left Slice Only) 710

Remove 710

Clean 711

Inspect 711

Install 711

Load Sense and Pressure Controller Valve on Pump 711

Remove 711

Clean 711

Inspect 711

Assemble 712

Install 712

Adjustment of Pressure Controller on Pump 712

Adjustment of Load Sense Controller on the Secondary Variable Pump 713

Adjustment of Load Sense Controller on the Primary Variable Pump 714

Lowering Control Valve 715

Remove 715

Clean 716

Inspect 716

Install 716

Directional Control Valve 716

Remove 716

Clean 716

Inspect 716

Assemble 717

Install 717

Manual End Cap 717

Remove 718

Clean 718

Inspect 718

Assemble 718

Install 718

Troubleshooting 718

Lift, Tilt, and/or Aux function does not move when applied Steering is operating normal 718

The truck is not

capable to lift

rated load at expected

max lift

speed 719

Tilt function

shakes 719

It is not

possible to

lower the

mast with

ignition key

turned to

ON 720

Steer and

brake accumulator

charge

function

does not operate 720

The truck is

hydraulically

loaded

during engine

start

Accumulator

charge

and steering

is possible

during

XMSN calibration 720

Torque Specifications 720

Torque Specifications 720

550061801 0100YRM1594 (11 2015) US EN 723

General 727

Description 727

Air Cleaner 728

Air Cleaner Assembly, Tier 3/Stage III A, F876/F877 729

Remove 729

Install 729

Air Cleaner Assembly, Tier 4i/Stage III B, F876/F877 730

Remove 730

Install 731

Exhaust System 732

Exhaust Assembly, Tier 3/Stage III A, F876/F877 732

Remove 732

Install 733

Exhaust Assembly, Tier 4i/Stage III B, F876/F877 733

Remove 733

Install 735

Hood Assembly 736

Remove 736

Install 738

Hydraulic Tank 738

Remove 738

Inspect 741

Clean 741

Additional Preparations for Repair 741

Repair 742

Preparations for use After Repair 742

Install 742

Fuel Tank 744

Remove 744

Repair 748

Install 748

Cab 749

Raising and Lowering Cab 749

Raise Cab 749

Lower Cab 750

Cab Repair 750

Remove 750

Install 752

Oil Filling for Cab Tilt System 752

Engine 753

Remove 754

Install 760

Counterweight 763

General 763

Remove 763

Install 764

Label Replacement 765

550061806 0700YRM1595 (02 2017) US EN 769

General 773

773

Cooling System Description 773

Cooling Cores 773

Fan 774

Fan Clutch 774

Fan Clutch Engagement 774

Shroud 776

Engine Cooling System 776

Water Pump 776

Thermostat 776

Expansion Tank And Radiator Cap 777

Cab Heater 778

Coolant 778

DEF Heater 780

Charge Air Cooling System 780

Transmission Oil Cooling System 780

Hydraulic Oil Cooling System 780

Hydraulic Oil Cooling 780

Oil Filtration and Oil Cooling 782

Brake Cooling 782

Hydraulic Control System 782

Service and Repair 782

Cooling System Checks 783

Basic Checks 783

Coolant Quality Checks 783

Coolant Flow Checks 784

Thermostat 784

Water Pump 785

Cooling Core Efficiency 785

Cooling Core Flow Restrictions 786

Engine Leak Tests 786

External Leak Test 786

Check for Coolant Leak Into The Engine Oil Sump 787

Combustion Leak Test 788

Engine Cooling System Maintenance 788

Draining the Engine Cooling System 788

Filling the Engine Cooling System 789

Flushing the Engine Cooling System 789

Cleaning the Engine Cooling System 790

Remove and Replace 790

Fan 790

Remove 790

Install 790

Drive Belt 791

Remove 791

Install 791

Belt Tensioner 792

Inspect 792

Remove 792

Install 792

Water Pump 793

Inspect 793

Remove 793

Install 793

Thermostat 794

Remove 794

Inspect 794

Install 794

Cooling Core Assembly 794

Remove 795

Cooling Cores 800

Disassembly 800

Assembly 800

Install 800

550061811 2200YRM1592 (09 2013) US EN 805

toc 805

Electrical System 805

Safety Precautions Maintenance and Repair 806

General 809

Electrical Schematic and System Description 810

Electrical Schematic 810

Schematic Location Number 813

Electrical Components 813

Electrical Wires 813

Wire Identification Number 813

Electrical Wire Colors 814

Wire Harnesses 814

Harness Interconnection 815

Electrical Connectors 815

Connector Types 815

Connector Identification 815

Connector Pin Numbers 816

Connector Description 816

Fuses 816

Relays 822

Flyback Diodes 823

CAN (Controller Area Network) 823

Diagnostic 824

Troubleshooting 824

Instrument Panel 824

General Fault Finding 827

Preparation 827

Define the Problem Area 827

Identify Possible Causes of Malfunction 827

Determine the Most Probable Cause 827

Fuse Check 827

Wiring Check 827

Component Check 827

Repair and Test 827

Wire Harness Identification and Connector Location 828

tables 805

Table 1 Electrical Schematic Index, Tier III 811

Table 2 Electrical Schematic Index, Tier IV 811

Table 3 Function ID Numbers 813

Table 4 Electrical Wire Colors 814

Table 5 Harnesses by Option 814

Table 6 Connector Types 815

Table 7 Legend for Starter and Grid Heater Relays 818

Table 8 Flyback Diodes 823

Table 9 Legend for Figure 7, Figure 8 and Figure 9 826

Table 10 Connector Overview 828

Table 11 Legend for Figure 10 and Figure 11 842

Table 12 Legend for Figure 12 845

550061816 8000YRM1591 (10 2013) US EN 857

550061821 8000YRM1593 (07 2019) US EN 931

General 937

Serial Number Data 937

Truck Handling Procedures 938

Moving and Towing a Lift Truck 938

Precautions 938

Moving the Truck 938

Putting a Lift Truck on Blocks 939

Raising the Drive Tires 939

Raising the Steering Tires 939

Cleaning a Lift Truck 940

Safety Procedures Before Starting Maintenance 941

Making Checks From the Driver Seat with Engine Running 941

Fire Hazard 941

Hydraulic Service Switch 942

Transmission Calibration Switch 942

Wait 100 Seconds Before Disconnecting Battery 942

Periodic Maintenance Schedule 942

Daily Inspection 943

Daily Condition Checks 943

Daily Fluid Level Checks 944

Daily Checks from the Driver Seat with Engine Running 945

Initial Inspection 946

First Inspection after First 100 Hours of Operation 946

Periodic Maintenance 946

Inspect and Adjust 946

Lubricate 950

Change 950

Periodic Maintenance Procedures 952

Air Conditioning System 952

Attachment 952

Brake System Accumulator 952

Brake Cooling Filter 952

Cab Air Filter 953

Cab Door Hinges 953

Control Levers, Switches, and Pedals 953

Cooling System 953

Coolant Hoses 953

Coolant Level 954

Coolant Quality 954

Cooling Fan 954

Cooling Fan Drive Belt 955

Cooling Fan Drive Belt Tensioner and Pulleys 955

Bearing Condition 955

Pulley Alignment 955

Tensioner Condition 955

Crankcase Breather 956

Drive Axle and Differential 957

Check Oil level 957

Change Oil 957

Drive Shaft 957

Engine Air Filter 957

Engine Air Intake Piping and Charge Air Piping 958

Engine and Transmission Mounts 958

Engine Compartment 958

Engine Oil 958

Engine Oil Level 958

Engine Oil and Engine Oil Filter 959

Engine Valve Adjustment 959

Fault Codes 962

Forks 962

Fork Pins, Carriage Pins, and Carriage Sliding Surfaces 963

Frame, Mast, Carriage and Attachment 963

Fuel, Oil or Coolant Leaks 964

Fuel Filter and Water Separator Filter 964

Header Hose Assembly 964

Horn, Gauges, Lights, Alarms and Control System 965

Hydraulic System Oil 965

Hydraulic Oil Testing Procedures 966

Hydraulic Oil Replacement 966

Hydraulic Tank Breather 967

Hydraulic Tank Return Filter 967

Inching Pedal Sensor Calibration 968

Lift Chains 968

Check and Lubricate Lift Chains 968

Adjust Lift Chains 968

Inspect Lift Chains 969

Chain Elongation 969

Lift Chain Wear and Damage 970

Lift System Accumulator (Optional) 970

Load Rollers 970

Carriage Load Rollers 970

Inner Mast Load Rollers 971

Mast, Carriage, and Attachment 971

Mast Pivot Pins 971

Operator Presence System 971

Operator Restraint System 971

Seat Belt and Seat Rails 971

Steering Column Latch 972

Parking and Service Brakes 972

Radiator Assembly 973

Steering Axle Grease Fittings 973

King Pins 973

Tie Rod Pins 973

Steering System 973

Steering Wheel Hub Bearings 973

Remove and Disassemble 973

Clean and Inspect 973

Assemble and Install 974

Tilt Cylinder Pivot Pins 974

Transmission 974

Transmission Clutch Calibration 974

Transmission Oil Level 975

Transmission Oil and Oil Filter 975

Vibration Damper 976

Warning and Safety Labels 976

Windows and Mirrors 976

Windshield Washer Fluid Level 976

Wheels and Tires 977

Wheels, Tires, and Tire Pressure 977

Remove Wheels from Lift Truck 978

Adding Air Pressure to Pneumatic Tires 984

Install Wheels on Lift Truck 989

Capacities and Specifications 990

Approved Fuel and Engine Oils 990

Approved Oils, Fluids, and Grease 990

Engine Oil Viscosity 991

Lift Chain Lubricant Requirements 991

Fuses and Relays 991

Side Console 992

Relays 995

550061826 8000YRM1596 (10 2016) US EN 997

Counterweight Weights 1001

Lift Truck Weights 1002

Capacities 1002

Engine Specifications 1003

Hydraulic System 1004

Electrical System 1004

Tire Sizes 1005

Mast Speeds 1005

Torque Specifications, General 1007

Transmission ZF 1007

Driveline and Axle 1007

Counterweight 1007

Differential 1007

Brakes – Wet 1007

Steering 1007

Wheel Nuts 1007

Hydraulic System 1008

Mast 1008

Carriage 1008

Tilt Cylinders 1008

Wiper Arms, Front 1009

Torque Specifications, Cummins Diesel 1009

Lubrication System 1009

550088524 4000YRM1647 (07 2016) US EN 1013

Series Code / Model Designation Reference Table 1019

General 1019

Description And Operation 1019

Mast System 1019

Tilting 1019

Lifting 1020

Operation 1020

Pilot Operated Check Valves 1021

Gland Lubrication 1022

Emergency Lowering Valve 1022

Operation 1022

Lift Chains 1023

Elongation Through Wear 1023

Speed of Wear 1023

Plate Height Wear 1024

Lubrication 1024

Restoring The Oil Film 1024

Maintenance 1024

Maintaining The Presence of Oil 1025

Corrosion Protection 1025

Requirements for Chain Lubricant 1025

Load Rollers 1026

Bearing Blocks 1026

Carriage 1027

Standard Carriage with Manual Fork Positioning 1027

Standard Carriage with Hydraulic Fork Positioning 1027

Dual Function Side Shift and Fork Positioning (DFSSFP) Carriage 1028

Integral Side Shift 1028

Carriage Valve 1029

Alternating Pressure and Tank (P & T) 1029

Fixed Pressure and Tank (P & T) 1029

Flow Divider for Simultaneous Fork Positioning 1029

Valve for Dual Function with Side Shift and Fork Positioning (DFSSFP) 1031

Fixed Pressure and Tank System (Fixed P & T) 1033

Forks 1035

Safety Procedures When Working Near Mast 1036

Before Starting Repairs to the Hydraulic System, Always: 1037

Remove and Replace 1037

Forks 1037

Remove 1037

Install 1038

Fork Guide And Fork Pin 1039

Remove 1039

Install 1039

Carriage 1040

1040

Remove 1040

Install 1041

Carriage Bearing Blocks 1042

Remove 1042

Install 1043

1043

Carriage Load Rollers 1043

Replace 1043

1045

Side Shift Cylinder 1045

Remove 1045

Disassemble 1045

Clean And Inspect 1046

Assemble 1046

Install 1047

Fork Positioner Cylinder 1047

Remove 1047

Disassemble 1048

Clean and Inspect 1048

Assemble 1049

Install 1049

Carriage Valves 1049

Remove 1049

Install 1050

1050

Valve for Fixed P & T Systems 1050

Remove and Disassemble 1050

Clean and Inspect 1052

Assemble and Install 1052

Flow Divider for Simultaneous Fork Positioning Valve 1053

Restrictor Valve and Relief Valve Replacement 1053

Dual Function Valve for Side Shifting and Fork Positioning 1053

Solenoid Valve Replacement 1053

Relief Valve Replacement 1054

Remove 1054

Install 1054

Mast 1054

Lift Chains and Top Chain Anchor 1054

Remove 1054

Install 1054

Chain Anchor On Carriage 1055

Remove 1055

Install 1055

Chain Sheave 1056

Remove 1056

Install 1056

Header Hoses 1057

Remove 1057

Install 1059

Electric Mast Cable 1059

Remove 1059

Install 1059

Hose Sheave 1060

Remove and Disassemble 1060

Assemble and Install 1060

Mast Assembly 1061

Remove 1061

Disassemble 1063

Assemble 1064

Install 1065

Inner Mast Load Rollers 1067

Replace 1067

Mast Bearing Blocks 1068

Remove 1068

Install 1068

Lift Cylinders 1069

Remove 1069

Disassemble 1072

Clean and Inspect 1072

Assemble 1072

Install 1073

Tilt Cylinders 1074

Remove 1074

Disassemble 1075

Clean and Inspect 1075

Assemble 1075

Install 1076

Checks and Adjustments 1077

General Checks 1077

Mast Condition Check 1077

Mast Operation Check 1078

Counterbalance Valve Check (for E876 and E877 Only) 1078

Fork Inspection and Adjustment 1078

Lift Chain Inspection 1079

Lift Chain Lubricant Requirements 1080

Lift Chain Lubrication Procedure 1080

Leak Checks 1080

Mast Vertical Creep 1080

Mast Tilt Drift 1081

Adjustments 1081

Lift Cylinder Shimming 1081

Lift Chain and Fork Height Adjustment 1083

Header Hose Tension Adjustment 1085

Electric Mast Cable Tension Adjustment 1085

Counterbalance Valve Adjustment 1085

Tilt Cylinder Backward Tilt Angle Adjustment 1086

Mast Support Pad Adjustment 1086

Troubleshooting 1086

Introduction 1087

No Hydraulic Movement With Engine Running 1087

Initial Basic Check 1087

1088

Electrical Supply 1088

Hydraulic Supply 1088

Fault Code 1088

No Lowering Possible with Engine OFF 1089

Incorrect Movement 1089

Irregular (shaking) Movement

or

Slight Carriage Movement When Starting Engine

1089

Unequal Movement of Left And Right Tilt Cylinder 1089

Insufficient Lifting Speed 1089

Insufficient Lifting Capacity 1090

Incorrect Lowering Speed 1090

Lift Cylinder Creep 1090

Tilt Cylinder Creep 1090