$45.95

Yale Forklift G807 (ERP030VT, ERP035VT, ERP040VT) Service Manual – PDF DOWNLOAD

Yale Forklift G807 (ERP030VT, ERP035VT, ERP040VT) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift G807 (ERP030VT, ERP035VT, ERP040VT) Service Manual – PDF DOWNLOAD

Language : English

Pages : 4024

Downloadable : Yes

File Type : PDF

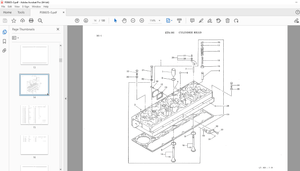

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift G807 (ERP030VT, ERP035VT, ERP040VT) Service Manual – PDF DOWNLOAD

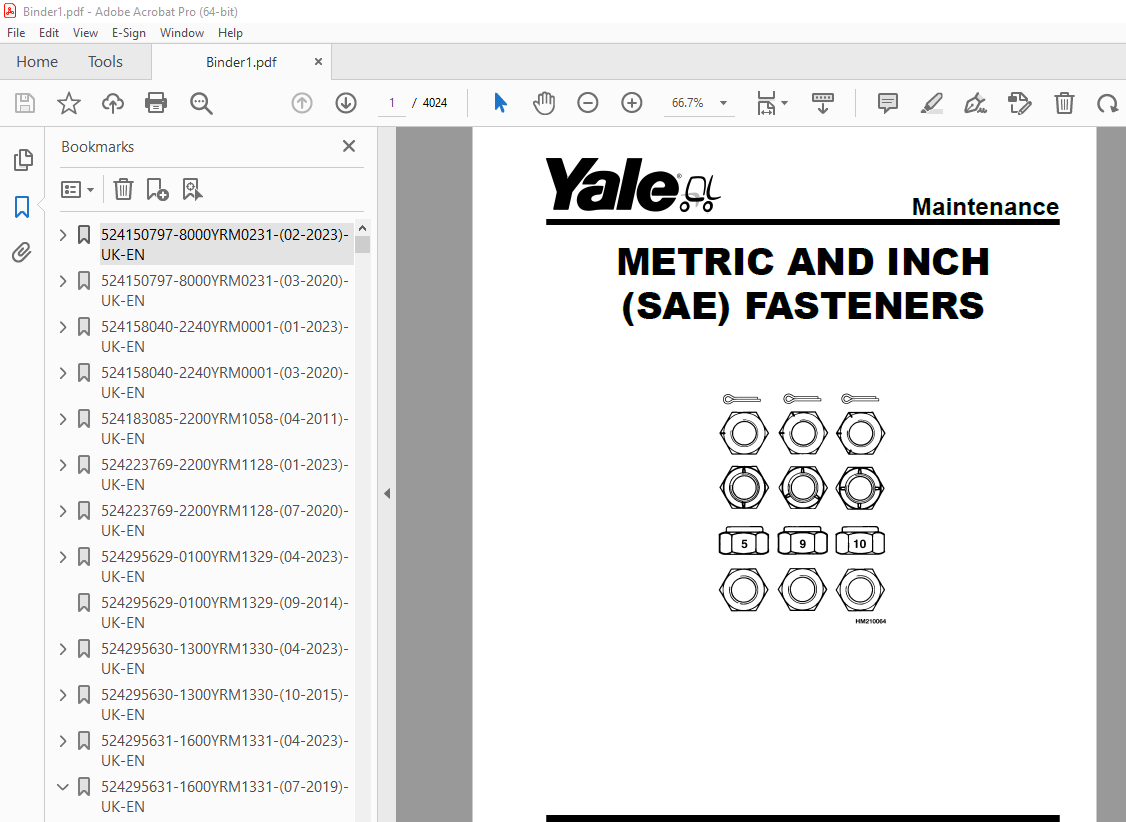

524150797-8000YRM0231-(02-2023)-UK-EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797-8000YRM0231-(03-2020)-UK-EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

524158040-2240YRM0001-(01-2023)-UK-EN 43

General 49

Battery Type 49

Lead-Acid Batteries 49

Lithium-Ion Batteries 50

Specific Gravity 50

Chemical Reaction in a Cell 50

Electrical Terms 52

Battery Selection 53

Battery Voltage 54

Battery as a Counterweight 54

Battery Ratings 54

Kilowatt-Hours 54

Battery Maintenance 55

Safety Procedures 55

Maintenance Records 55

New Battery 55

Cleaning Battery 56

Adding Water to Battery 58

Hydrometer 58

Battery Temperature 59

Charging Battery 60

Types of Battery Charges 61

Methods of Charging 62

Troubleshooting Charger 63

Knowing When Battery Is Fully Charged 63

Where to Charge Batteries 63

Equipment Needed 63

Battery Connectors 64

Battery Care 64

Troubleshooting 66

524158040-2240YRM0001-(03-2020)-UK-EN 71

General 75

Battery Type 75

Lead-Acid Batteries 75

Lithium-Ion Batteries 76

Specific Gravity 76

Chemical Reaction in a Cell 76

Electrical Terms 78

Battery Selection 78

Battery Voltage 79

Battery as a Counterweight 80

Battery Ratings 80

Kilowatt-Hours 80

Battery Maintenance 80

Safety Procedures 80

Maintenance Records 81

New Battery 81

Cleaning Battery 81

Adding Water to Battery 83

Hydrometer 84

Battery Temperature 85

Charging Battery 86

Types of Battery Charges 86

Methods of Charging 88

Troubleshooting Charger 88

Knowing When Battery Is Fully Charged 89

Where to Charge Batteries 89

Equipment Needed 89

Battery Connectors 90

Battery Care 90

Troubleshooting 92

524183085-2200YRM1058-(04-2011)-UK-EN 97

toc 97

Troubleshooting and Adjustments Using the AC Controls Program (E 97

Safety Precautions Maintenance and Repair 98

General 101

Computer Requirements 101

Software, Install 101

Language Selection 101

Demo Mode 102

Connect PC to Lift Truck 106

Starting AC Controls Program 108

Lift Truck Control Setup 113

Change Lift Truck Serial Number or Hourmeter 113

Setting Factory Default Values or Changing Lift Truck Parameters 114

Create New Custom Lift Truck Configuration 120

Lift Truck Configuration Properties 123

Import New Lift Truck Configuration From Disk 126

Delete Custom Lift Truck Configuration or Password File 128

Dash Display 131

Custom Display Languages 131

Download Display Language 133

Clear Operator Log 133

Password Functions 136

Enable/Disable Password and Lift Truck Inspection Functions 136

Truck Inspection Checklist 136

Password 136

Password Properties 136

Create New Password File 141

Download Passwords 142

Upload Passwords 144

Reports Menu 146

Devices Report 146

Custom Report 146

Password Report 146

Operator Report 153

Current Settings Report 156

Status Code Report 160

Status Codes Log 163

Troubleshooting 165

Diagnostics 165

Help Menu 168

General 168

Contents 168

Technical Support 168

About Electric Truck AC Controls Program 168

524223769-2200YRM1128-(01-2023)-UK-EN 175

Series Code / Model Designation Reference Table 183

General 185

Deutsch Crimping Tool 186

How to Strip a Wire for Use With Deutsch Crimping Tool 186

How to Crimp With the Deutsch Crimping Tool 187

Calibration Test for the Deutsch Crimping Tool 189

Deutsch Connectors 191

DT, DTM, and DTP Series Connectors 191

HD Series Connectors 234

Metri-Pack Connectors 256

Remove and Install 256

Micro-Pack Connectors 259

Weather-Pack Connectors 260

AMPSEAL Crimping Tools 262

AMP Hand Crimping Tool With Certi-Crimp 262

Description 262

Stripping Wire for Use with AMP Hand Crimping Tool 263

Insulation Crimp Adjustment 264

Maintenance and Inspection for AMP Hand Crimping Tool 264

AMP Hand Crimping Tool 264

Crimp Height Inspection 264

How to use AMP Hand Crimping Tool 265

AMP Pro-Crimper II Tool 265

Description 265

Remove and Install Die Set and Locator Assembly 266

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 266

Contact Support Adjustment 267

Crimp Height Adjustment 268

Maintenance and Inspection Procedures 268

PRO-CRIMPER II Tool 268

Crimp Height Inspection 268

How to Use AMP PRO-CRIMPER II Tool 269

AMPSEAL Connector Assemblies 270

Description for Plug Connector Assembly 270

Seal Plug 271

Contact Crimping 271

Description for Plug Connector and Header Assembly 276

Voltage Reading 279

Seal Plug 279

Contact Crimping 279

AMP Superseal 1 5 Crimping Tools 286

Mini Mic Receptacle and Tab Contacts 286

Description 286

Crimping Conditions and Measurements 286

Insertion of Rubber Seal on Cable 288

AMP Hand Application Tool 293

Description 293

Maintenance and Inspection 293

Crimp Height Inspection 293

Crimp Height Adjustment 294

How to Use AMP Hand Application Tool 294

AMP Pro-Crimper II Tool 295

Description 295

Remove and Install Die Set and Locator Assembly 295

Adjustments 296

Contact Support 296

Crimp Height 297

Inspections and Maintenance 298

Crimp Height Inspection 298

Visual Inspection 298

Maintenance 299

How to Use Pro-Crimper II Tool 299

AMP Superseal 1 5 Connector Assemblies 300

Description 300

Repair and Maintenance 307

Panel Mount Option 307

AMP Fastin-Faston Hand Tools 308

Description – AMP Double Action Hand Tool 308

Maintenance and Inspection Procedures 308

Daily Maintenance 308

Periodic Tool Inspection 309

Lubrication 309

Visual Inspection 309

Crimp Height Inspection 309

Certi-Crimp Ratchet Inspection 310

How to Use AMP Double Action Hand Tool 311

Description – AMP Extraction Tool 312

Maintenance and Inspection 313

How to Use AMP Extraction Tool 313

AMP Fastin-Faston Receptacles and Housings 315

Description 315

Wire Repair 323

Wire Splicing Requirements 323

Deutsch Jiffy Splice 324

Twisted/Shielded Cable and Leads Repair 330

Special Tools 332

524223769-2200YRM1128-(07-2020)-UK-EN 341

Series Code / Model Designation Reference Table 347

General 350

Deutsch Crimping Tool 350

How to Strip a Wire for Use With Deutsch Crimping Tool 350

How to Crimp With the Deutsch Crimping Tool 351

Calibration Test for the Deutsch Crimping Tool 353

Deutsch Connectors 355

DT, DTM, and DTP Series Connectors 355

HD Series Connectors 397

Metri-Pack Connectors 420

Remove and Install 420

Micro-Pack Connectors 422

Weather-Pack Connectors 423

AMPSEAL Crimping Tools 425

AMP Hand Crimping Tool With Certi-Crimp 425

Description 425

Stripping Wire for Use with AMP Hand Crimping Tool 425

Insulation Crimp Adjustment 426

Maintenance and Inspection for AMP Hand Crimping Tool 426

AMP Hand Crimping Tool 426

Crimp Height Inspection 426

How to use AMP Hand Crimping Tool 427

AMP Pro-Crimper II Tool 427

Description 427

Remove and Install Die Set and Locator Assembly 428

Stripping Wire for Use With AMP PRO-CRIMPER II Tool 429

Contact Support Adjustment 429

Crimp Height Adjustment 430

Maintenance and Inspection Procedures 430

PRO-CRIMPER II Tool 430

Crimp Height Inspection 430

How to Use AMP PRO-CRIMPER II Tool 431

AMPSEAL Connector Assemblies 432

Description for Plug Connector Assembly 432

Seal Plug 433

Contact Crimping 433

Description for Plug Connector and Header Assembly 438

Voltage Reading 440

Seal Plug 440

Contact Crimping 440

AMP Superseal 1 5 Crimping Tools 447

Mini Mic Receptacle and Tab Contacts 447

Description 447

Crimping Conditions and Measurements 447

Insertion of Rubber Seal on Cable 449

AMP Hand Application Tool 454

Description 454

Maintenance and Inspection 454

Crimp Height Inspection 454

Crimp Height Adjustment 455

How to Use AMP Hand Application Tool 455

AMP Pro-Crimper II Tool 456

Description 456

Remove and Install Die Set and Locator Assembly 457

Adjustments 457

Contact Support 457

Crimp Height 458

Inspections and Maintenance 459

Crimp Height Inspection 459

Visual Inspection 459

Maintenance 460

How to Use Pro-Crimper II Tool 460

AMP Superseal 1 5 Connector Assemblies 461

Description 461

Repair and Maintenance 468

Panel Mount Option 468

AMP Fastin-Faston Hand Tools 469

Description – AMP Double Action Hand Tool 469

Maintenance and Inspection Procedures 469

Daily Maintenance 469

Periodic Tool Inspection 470

Lubrication 470

Visual Inspection 470

Crimp Height Inspection 470

Certi-Crimp Ratchet Inspection 471

How to Use AMP Double Action Hand Tool 472

Description – AMP Extraction Tool 473

Maintenance and Inspection 473

How to Use AMP Extraction Tool 474

AMP Fastin-Faston Receptacles and Housings 475

Description 475

Wire Repair 482

Wire Splicing Requirements 482

Deutsch Jiffy Splice 483

Twisted/Shielded Cable and Leads Repair 488

Special Tools 491

524295629-0100YRM1329-(04-2023)-UK-EN 499

Introduction 505

General 505

Description of Operation 506

Discharging the Capacitors 507

Rapid Charge 507

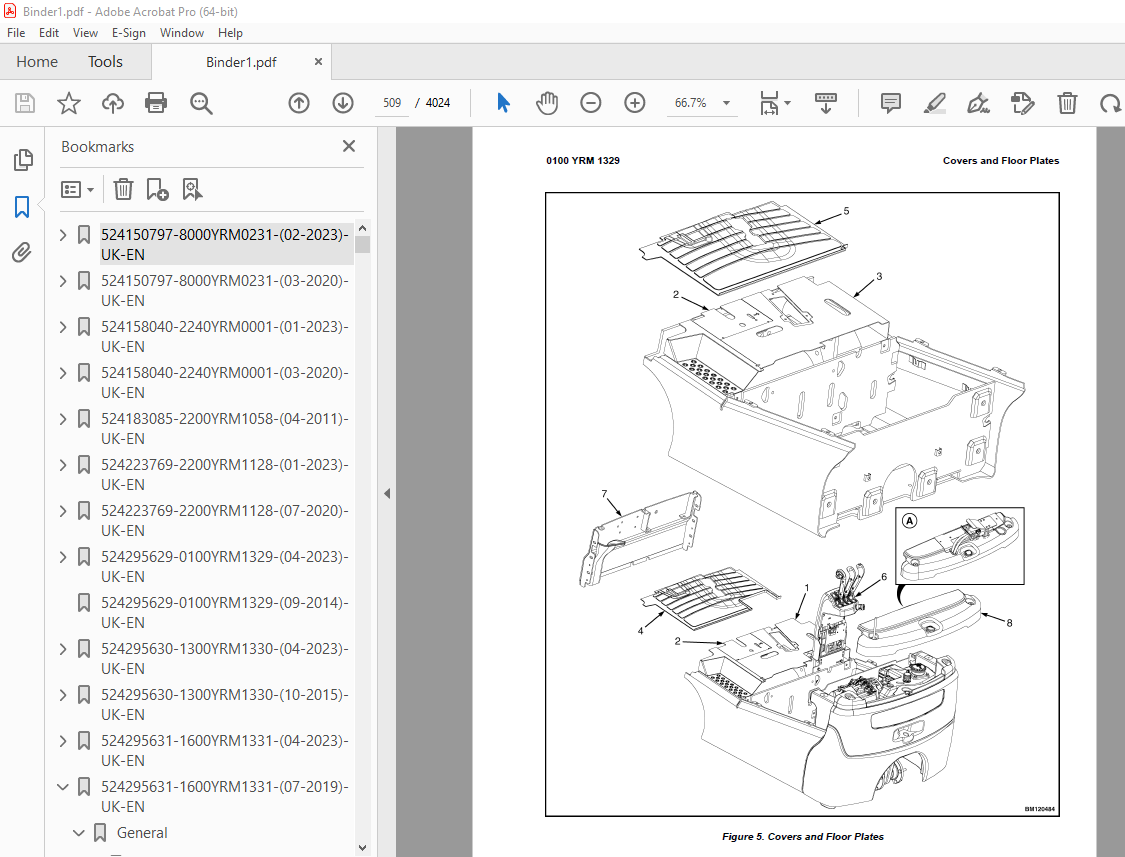

Covers and Floor Plates 508

Overhead Guard Replacement 511

Remove 511

Install 516

Hood and Seat Assembly 517

Remove 520

Install 522

Ground Test 522

Counterweight Replacement 523

Remove 524

Install 529

Safety Labels 531

Painting Instructions 536

Battery Specifications 537

European Model Trucks ERP15-20VT (G807) 537

US Model Trucks ERP030-040VT (G807) 538

European Model Trucks ERP16-20VF (A955) 539

US Model Trucks ERP30-40VF (A955) 540

524295629-0100YRM1329-(09-2014)-UK-EN 543

524295630-1300YRM1330-(04-2023)-UK-EN 585

General 591

Discharging the Capacitors 592

Special Tools 592

Transaxle Assembly 593

Remove Transaxle From Frame 593

Remove the Parking Brake and Traction Motor 594

Install Parking Brake and Traction Motor 595

Install Transaxle to Frame 596

Maintenance and Repair 597

Speed Sensor Repair 597

Trunnion Cap Repair 598

Fluid Level Check 598

Fluid Change 599

Breather Repair 600

Stud Repair 601

Brake Cylinder Repair 602

Input Seal Repair 604

Cover to Housing Seal 604

During the Transaxle Warranty Period 604

After the Transaxle Warranty Period 605

Removing the Cover 605

Installing the Cover 606

Wet Brakes 607

Electronic Brake (E-Brake) 609

524295630-1300YRM1330-(10-2015)-UK-EN 611

General 615

Discharging the Capacitors 616

Special Tools 616

Transaxle Assembly 616

Remove Transaxle From Frame 617

Remove the Parking Brake and Traction Motor 618

Install Parking Brake and Traction Motor 619

Install Transaxle to Frame 620

Maintenance and Repair 620

Speed Sensor Repair 620

Trunnion Cap Repair 621

Fluid Level Check 622

Fluid Change 623

Breather Repair 624

Stud Repair 625

Brake Cylinder Repair 626

Input Seal Repair 627

Cover to Housing Seal 628

During the Transaxle Warranty Period 629

After the Transaxle Warranty Period 630

Removing the Cover 630

Installing the Cover 630

Wet Brakes 631

Electronic Brake (E-Brake) 633

524295631-1600YRM1331-(04-2023)-UK-EN 637

General 643

Introduction 643

Discharging The Capacitors 643

Steering Pressure Check, Lift Trucks Equipped With Hydraulic Steering 645

Operation Check 647

Steering Control Unit (SCU) Repair, Lift Trucks Equipped With Hydraulic Steering 648

Remove 648

Disassemble 651

Clean 656

Inspect 656

Assemble 656

Install 657

Steering Wheel and Fixed Steering Column Assembly Repair 659

Remove 659

Disassemble 662

Clean 664

Inspect 664

Assemble 664

Install 665

Gear Replacement for Lift Trucks Built Prior to 10/2008 666

Steering Wheel and Telescopic Column Assembly Repair 667

Remove 667

Disassemble 670

Clean 673

Inspect 674

Assemble 674

Install 675

Hydraulic Pump and Motor 682

Steering Actuator Components 682

Steer Tire and Wheel Assembly 682

Remove 682

Install 683

Wheel Hub Assembly, Lift Trucks Equipped With Hydraulic Steering 683

Remove 683

Clean 685

Inspect 686

Install 686

Wheel Hub Assembly, Lift Trucks Equipped With E-Steering 686

Remove 686

Clean 687

Inspect 688

Install 688

Steering Axle Assembly, Lift Trucks Equipped With Hydraulic Steering 688

Remove 688

Disassemble 689

Clean 690

Inspect 690

Assemble 690

Install 691

Steering Axle Assembly, Lift Trucks Equipped With E-Steering 691

Remove 691

Disassemble 694

Clean 696

Inspect 696

Assemble 696

Install 697

Torque Specifications 698

Fixed Steering Column 698

Telescopic Steering Column 698

Steering Control Unit 698

Steer Axle, Lift Trucks Equipped With Hydraulic Steering 698

Steer Axle, Lift Trucks Equipped With E-Steering 698

524295631-1600YRM1331-(07-2019)-UK-EN 701

General 705

Introduction 705

Discharging The Capacitors 705

Steering Pressure Check, Lift Trucks Equipped With Hydraulic Steering 706

Operation Check 708

Steering Control Unit (SCU) Repair, Lift Trucks Equipped With Hydraulic Steering 708

Remove 708

Disassemble 711

Clean 716

Inspect 716

Assemble 716

Install 717

Steering Wheel and Fixed Steering Column Assembly Repair 718

Remove 718

Disassemble 722

Clean 723

Inspect 724

Assemble 724

Install 724

Gear Replacement for Lift Trucks Built Prior to 10/2008 725

Steering Wheel and Telescopic Column Assembly Repair 726

Remove 726

Disassemble 729

Clean 733

Inspect 733

Assemble 733

Install 734

Hydraulic Pump and Motor 741

Steering Actuator Components 741

Steer Tire and Wheel Assembly 741

Remove 741

Install 742

Wheel Hub Assembly, Lift Trucks Equipped With Hydraulic Steering 742

Remove 742

Clean 744

Inspect 745

Install 745

Wheel Hub Assembly, Lift Trucks Equipped With E-Steering 745

Remove 745

Clean 746

Inspect 747

Install 747

Steering Axle Assembly, Lift Trucks Equipped With Hydraulic Steering 747

Remove 747

Disassemble 748

Clean 749

Inspect 749

Assemble 749

Install 750

Steering Axle Assembly, Lift Trucks Equipped With E-Steering 750

Remove 750

Disassemble 753

Clean 755

Inspect 755

Assemble 755

Install 756

Torque Specifications 756

Fixed Steering Column 756

Telescopic Steering Column 756

Steering Control Unit 756

Steer Axle, Lift Trucks Equipped With Hydraulic Steering 756

Steer Axle, Lift Trucks Equipped With E-Steering 756

524295632-1800YRM1332-(04-2023)-UK-EN 759

Introduction 765

General 765

Discharging the Capacitors 766

Brake Pedal Assembly Repair 767

Hydraulic Brake System 767

Remove 767

Disassemble 768

Assemble 768

Install 768

Electronic Brake (E-Brake) System 769

Remove 769

Disassemble 770

Assemble 771

Install 772

Adjustments 772

Brake Pedal Adjustment 772

Clevis Adjustment 772

Master Cylinder Repair 774

Remove 774

Disassemble 775

Clean and Inspect 777

Assemble 777

Install 777

Adjustments 778

Bleed the Brake System 778

Adjust Linkage 778

Brake Lines 780

Brake Line Replacement 780

Parking Brake 781

Manual Release Lever 781

Adjust Cable 781

Replace Cable 781

Remove 782

Install 783

524295632-1800YRM1332-(11-2015)-UK-EN 785

Introduction 789

General 789

Discharging the Capacitors 789

Brake Pedal Assembly Repair 790

Hydraulic Brake System 790

Remove 790

Disassemble 791

Assemble 792

Install 792

Electronic Brake (E-Brake) System 793

Remove 793

Disassemble 794

Assemble 795

Install 796

Adjustments 796

Brake Pedal Adjustment 796

Clevis Adjustment 796

Master Cylinder Repair 798

Remove 798

Disassemble 798

Clean and Inspect 802

Assemble 802

Install 802

Adjustments 802

Bleed the Brake System 802

Adjust Linkage 803

Brake Lines 803

Brake Line Replacement 804

Parking Brake 805

Manual Release Lever 805

Adjust Cable 805

Replace Cable 805

Remove 806

Install 807

524295633-1900YRM1333-(07-2023)-UK-EN 811

General 817

Hydraulic Pump Repair 818

Remove 818

Disassemble 822

Inspect 824

Clean 824

Assemble 824

Install 824

Hydraulic Tank Assembly 826

Remove 826

Disassemble 828

Clean 829

Steam Method 829

Chemical Method 829

Inspect 830

Assemble 830

Install 830

Hydraulic Filter Replacement 831

Breather Clean and Inspect 832

Add Hydraulic Oil 833

Steer Accumulator Replacement for Lift Truck Models ERP030-40VF (A955) 834

Remove 834

Install 836

Specifications 837

524295633-1900YRM1333-(10-2015)-UK-EN 839

General 843

Hydraulic Pump Repair 844

Remove 844

Disassemble 847

Inspect 849

Clean 849

Assemble 849

Install 849

Hydraulic Tank Assembly 850

Remove 850

Disassemble 853

Clean 853

Steam Method 854

Chemical Method 854

Inspect 854

Assemble 854

Install 855

Hydraulic Filter Replacement 856

Breather Clean and Inspect 857

Add Hydraulic Oil 857

Steer Accumulator Replacement for Lift Truck Models ERP030-40VF (A955) 858

Remove 858

Install 858

Specifications 861

524306565-8000YRM1340-(03-2017)-UK-EN 865

General 869

Lubrication Specifications 869

Hydraulic System 871

Steering System 872

Tire Sizes 874

Torque Specifications 875

Electrical 875

Steering SystemLift Truck Models ERP15-20VT (G807) Manufactured Before November, 2014 and ERP030-040VT (G807) 875

Steering SystemLift Truck Models ERP15-20VT (G807) Manufactured After November, 2014 876

Hydraulic System 876

E-Hydraulic Control Valve 876

Transaxle 876

Mast Speeds 876

Maximum Carriage and Tilt Creep Rates 881

Tilt Angles 882

Transaxle Assembly 882

Travel Speeds 882

Battery 884

ERP15-20VT (G807) European Model Trucks 884

ERP030-040VT (G807) US Model Trucks 885

Battery Discharge Rate 886

524319495-2000YRM1334-(03-2023)-UK-EN 889

General 897

Lift Trucks ERP15-20VT (ERP030-040VT) (G807) and ERP16-20VF (ERP30-40VF) (A955) 897

Lift Trucks ERC22-35VG (ERC045-070VG) (A968), ERP22-35VL (ERP045-070VL) (A976), and ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 899

Lift Truck ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 903

Discharging the Capacitors 905

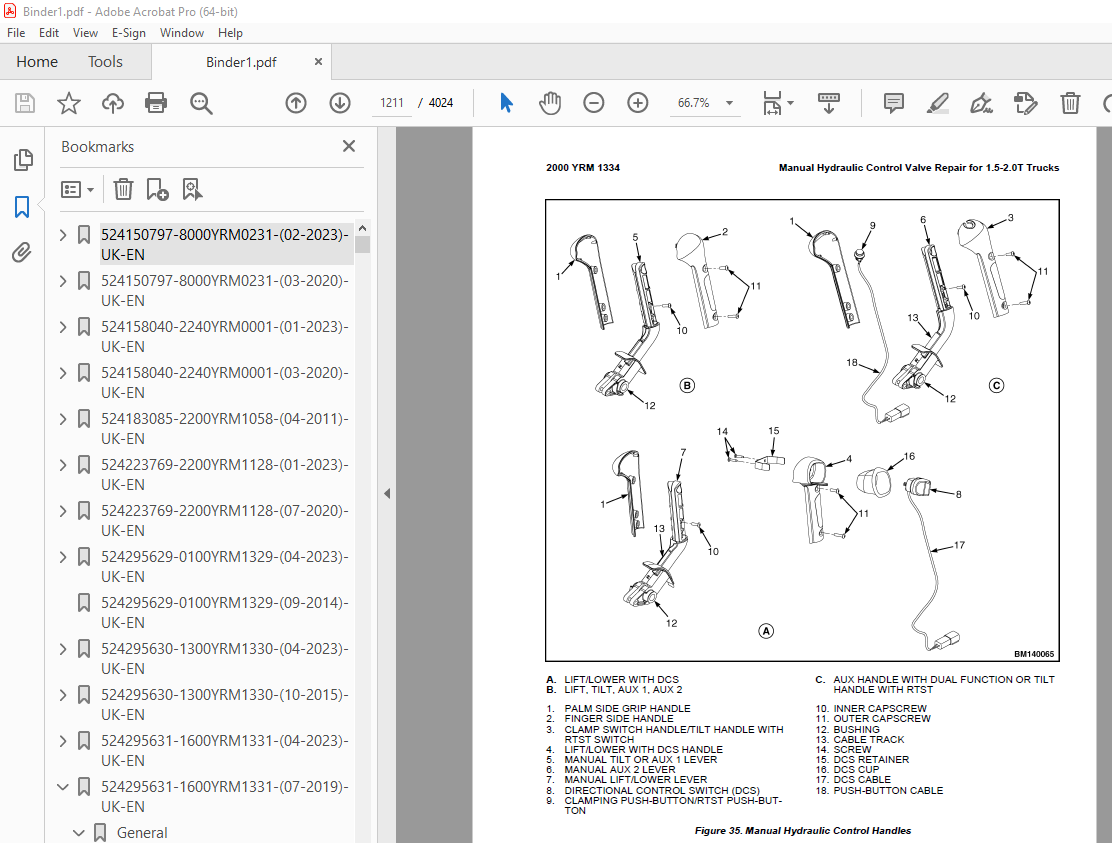

Manual Hydraulic Control Valve Repair for 1 5-2 0T Trucks 906

Remove 906

Beginning Steps 906

Disassemble Handles and Levers 919

Disassemble Manual Control Valve 922

Spool Seal Replacement 932

Clean 935

Inspect 935

Assemble Manual Control Valve 937

Assemble Handles and Levers 948

Install 951

Ending Steps 963

Manual Hydraulic Control Valve Repair for 2 0-3 5T Trucks and 4 0-5 0T Pneumatic Trucks 965

Remove 965

Disassemble Handles and Levers 981

Disassemble Manual Control Valve 984

Disassemble Valve 984

Disassemble Inlet Section 987

Disassemble Lift, Tilt, and Auxiliary Sections 987

Spool Seal Replacement 989

Clean 990

Inspect 991

Assemble Manual Control Valve 991

Assemble Lift, Tilt, and Auxiliary Sections 991

Assemble Inlet Section 992

Assemble Valve 993

Assemble Handles and Levers 1001

Install 1005

Ending Steps 1017

Manual Hydraulic Control Valve Repair for 4 0-5 5T Cushion Trucks 1018

Remove 1018

Disassemble Handles and Levers 1032

Disassemble Manual Control Valve 1034

Disassemble Valve 1034

Disassemble Inlet Section 1037

Disassemble Lift, Tilt, and Auxiliary Sections 1038

Spool Seal Replacement 1040

Clean 1041

Inspect 1041

Assemble Manual Control Valve 1042

Assemble Lift, Tilt, and Auxiliary Sections 1042

Assemble Inlet Section 1043

Assemble Valve 1044

Assemble Handles and Levers 1051

Install 1054

Ending Steps 1066

E-Hydraulic Control Valve Repair for 1 5-2 0T Trucks 1067

Remove 1067

Disassemble 1073

Clean 1080

Inspect 1080

Assemble 1080

Install 1088

E-Hydraulic Controls 1093

Replace E-Hydraulic Control Components 1094

E-Hydraulic Control Valve Repair for 2 0-3 5T Trucks and 4 0-5 0T Pneumatic Trucks 1095

Remove 1095

Initial Steps 1095

Fitting Removal for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 1095

Fitting Removal for Lift Truck ERP22-35VL (ERP045-070VL) (A976) and ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 1097

Electrical Disconnect and Control Valve Dismount 1099

Disassemble 1101

Clean 1106

Inspect 1106

Assemble 1106

Install 1114

Electrical Connect and Control Valve Mount 1114

Fitting Installation for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 1116

Fitting Installation for Lift Truck ERP22-35VL (ERP045-070VL) (A976) and ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 1118

Ending Steps 1119

E-Hydraulic Controls 1120

Replace E-Hydraulic Control Components 1120

E-Hydraulic Control Valve Repair for 4 0-5 5T Cushion Trucks 1121

Remove 1121

Initial Steps 1121

Fitting Removal 1121

Electrical Disconnect and Control Valve Dismount 1123

Disassemble 1125

Clean 1130

Inspect 1130

Assemble 1130

Install 1138

Electrical Connect and Control Valve Mount 1138

Fitting Installation 1140

Ending Steps 1141

E-Hydraulic Controls 1142

Replace E-Hydraulic Control Components 1142

Checks and Adjustments

for 1 5-2 0T Lift Trucks 1143

Manual Control Valve 1143

Primary Relief Valve 1143

Optional Auxiliary Port Relief Valve 1143

E-Hydraulic Control Valve 1144

Primary Relief Valve 1144

Optional Secondary Port Relief Valve 1145

Hydraulic System Air Removal 1146

Checks and Adjustments

2 0-5 5T Lift Trucks 1147

Manual Control Valve 1147

External Leakage 1147

Primary Relief Cartridge 1147

Secondary Relief Valve 1148

E-Hydraulic Control Valve 1148

Primary Relief Valve 1148

Secondary Relief Valve 1149

PPRV Pilot Pressure Test 1150

Hydraulic System Air Removal 1151

Position Sensor and OPS Check and Adjustment 1152

Position Sensor 1152

(OPS) Operator Presence Solenoid 1152

Manual Control Valve Re-Calibration 1152

Calibration Procedure 1153

Control Valve 1153

Torque Specifications

for 1 5-2 0T Lift Trucks 1154

Manual Hydraulic Control Valve 1154

Manual Control Valve Handles and Levers 1154

E-Hydraulic Control Valve 1154

Torque Specifications

for 2 2-5 5T Lift Trucks 1155

Manual Hydraulic Control Valve 1155

Manual Control Valve Handles and Levers 1155

Manual Control Valve Covers 1155

E-Hydraulic Control Valve 1155

524319495-2000YRM1334-(09-2014)-UK-EN 1157

524319496-2100YRM1382-(02-2018)-UK-EN 1407

Safety Procedures When Working Near Mast 1415

General 1417

Description 1418

Tilt Cylinder Repair for 2 0-5 5T Trucks 1418

Remove 1418

Disassemble 1420

Inspect 1421

Clean 1421

Assemble 1421

Install 1423

Tilt Cylinders, Adjust 1423

Tilt Cylinder Leak Check 1426

Tilt Cylinder Repair

for 1 0-2 0T Trucks 1427

Remove 1427

Disassemble 1429

Inspect 1431

Clean 1431

Assemble 1431

Install 1431

Tilt Cylinders, Adjust 1432

Tilt Cylinders Leak Check 1433

Lift Cylinder Repair

for 2 0-3 5T Trucks 1434

Main Lift Cylinders 1434

Remove 1434

Two-Stage FFL 1434

Three-Stage FFL 1436

Four-Stage FFL 1436

Two-Stage LFL 1437

Disassemble 1437

Two-Stage FFL 1437

Three-Stage FFL 1439

Four-Stage FFL 1439

Two-Stage LFL 1441

Clean 1442

Inspect 1442

Assemble 1442

Two-Stage FFL 1442

Three-Stage FFL 1442

Four-Stage FFL 1443

Two-Stage LFL 1443

Install 1444

Two-Stage FFL 1444

System Air Bleed Procedures 1444

Three-Stage FFL 1444

Four-Stage FFL 1445

Two-Stage LFL 1445

Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 1446

Main Lift Cylinder 1446

Remove 1446

Main Lift Cylinders – Two-Stage FFL Mast 1446

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 1448

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 1452

Main Lift Cylinder – Two-Stage LFL Mast 1452

Disassemble 1455

Main Lift Cylinders – Two-Stage FFL Mast 1455

Main Lift Cylinder – Three-Stage FFL Mast 1457

Main Lift Cylinder – Two-Stage LFL Mast 1457

Clean 1458

Inspect 1458

Assemble 1459

Main Lift Cylinder – Two-Stage FFL Mast 1459

Main Lift Cylinder – Three-Stage FFL Mast 1459

Main Lift Cylinder – Two-Stage LFL Mast 1459

Install 1460

Main Lift Cylinder – Two-Stage FFL Mast 1460

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 1460

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 1461

Main Lift Cylinder – Two-Stage LFL Mast 1462

System Air Bleed Procedures 1463

All Main Lift Cylinders 1463

Lift Cylinder Repair for 1 5-2 0T Trucks 1463

Main Lift Cylinder 1463

Remove 1463

Two-Stage FFL 1464

Three-Stage FFL 1464

Two-Stage LFL 1465

Four-Stage FFL 1467

Disassemble 1468

Two-Stage FFL 1468

Three-Stage FFL 1470

Two-Stage LFL 1470

Four-Stage FFL 1471

Clean 1474

Inspect 1474

Assemble 1474

Two-Stage FFL 1474

Three-Stage FFL 1475

Two-Stage LFL 1475

Four-Stage FFL 1476

Install 1477

Two-Stage FFL 1477

System Air Bleed Procedures 1477

Three-Stage FFL Mast 1477

Two-Stage LFL 1478

Four-Stage FFL 1478

Mast and Carriage Install for Two-Stage FFL, Three-Stage FFL, and Two-Stage LFL 1479

Mast and Carriage Installation for Four-Stage FFL 1479

Lift Cylinder Repair

for 4 0-5 5T Trucks 1480

Main Lift Cylinders 1480

Remove 1480

Two-Stage FFL 1480

Three-Stage FFL 1482

Two-Stage LFL 1482

Disassemble 1483

Two-Stage FFL 1483

Three-Stage FFL 1485

Two-Stage LFL 1486

Clean 1487

Inspect 1487

Assemble 1487

Two-Stage FFL 1487

Three-Stage FFL 1488

Two-Stage LFL 1488

Install 1489

Two-Stage FFL 1489

System Air Bleed Procedures 1489

Three-Stage FFL 1489

Two-Stage LFL 1490

Free-Lift Cylinder Repair

for 2 0-3 5T Trucks 1491

Free-Lift Cylinder 1491

Remove 1491

Two and Three-Stage FFL Mast 1491

Four-Stage FFL For Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1492

Disassemble 1494

Two and Three-Stage FFL Mast 1494

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1495

Clean 1495

Inspect 1495

Assemble 1496

Two and Three-Stage FFL Mast 1496

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1496

Install 1497

Two and Three-Stage FFL Mast 1497

Four-Stage FFL Mast for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 1497

Free Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 1498

Free-Lift Cylinder 1498

Remove 1498

Three-Stage FFL Mast 1498

Disassemble 1500

Clean 1501

Inspect 1501

Assemble 1501

Install 1501

Free Lift Cylinder Repair

for 1 5-2 0T Trucks 1502

Free-Lift Cylinder 1502

Remove 1502

Two and Three-Stage FFL Mast 1502

Four-Stage FFL Mast 1504

Disassemble 1506

Two-Stage and Three-Stage FFL Masts 1506

Four Stage FFL Mast 1507

Clean 1508

Inspect 1508

Assemble 1508

Two-Stage and Three-Stage FFL Masts 1508

Four-Stage FFL Mast 1509

Install 1509

Two-Stage and Three-Stage FFL Masts 1509

Four-Stage FFL Mast 1509

All Masts 1511

Free-Lift Cylinder Repair

for 4 0-5 5T Trucks 1512

Free-Lift Cylinder 1512

Remove 1512

Two and Three-Stage FFL Mast 1512

Disassemble 1513

Two and Three-Stage FFL Mast 1513

Clean 1514

Inspect 1514

Assemble 1514

Two and Three-Stage FFL Mast 1514

Install 1515

Two and Three-Stage FFL Mast 1515

Sideshift Cylinder Repair

for 1 5-3 5T Trucks Prior to December 2016 1515

Remove 1515

Disassemble 1519

Clean and Inspect 1521

Assemble and Install 1521

Sideshift Cylinder Repair

for 1 5-3 5T Trucks After December 2016 1522

Remove 1522

Disassemble 1526

Clean and Inspect 1528

Assemble and Install 1528

Integral Side-Shift Cylinder Gland Leak Checks 1530

Sideshift Cylinder Repair

for 4 0-5 5T Trucks 1531

Remove 1531

Disassemble 1531

Clean and Inspect 1533

Assemble and Install 1533

Fork Positioner Cylinder Repair Prior to December 2016 1533

Remove 1533

Disassemble 1534

Clean 1536

Inspect 1536

Assemble 1537

Install 1537

Fork Positioner Cylinder Adjustment 1537

Fork Positioner Cylinder Repair After December 2016 1538

Remove 1538

Disassemble 1538

Clean 1541

Inspect 1541

Assemble 1542

Install 1542

Fork Positioner Cylinder Adjustment 1542

Lift Cylinder Leak Check 1543

Seal Kit Installation 1543

External Installation (Seal and Back-Up Ring) 1544

Internal Installation (Piston Rod Assembly) 1544

Torque Specifications for Lift Truck Models ERC22-35VG (ERC045-070VG) (A968) and ERP22-25VL (ERP045-070VL) (A976) 1544

Tilt Cylinders 1544

Piston Rod Nut 1544

Gland 1545

Tilt Cylinder Mounting Capscrew 1545

Tilt Cylinder Rod End Capscrew 1545

Main and Free-Lift Cylinder 1545

Sideshift Cylinder 1545

Fork Positioner Cylinder 1545

Torque Specifications for Lift Truck Model ERP15VT (G807) 1545

Tilt Cylinders 1545

Main and Free-Lift Cylinders 1545

Sideshift Cylinder 1546

Torque Specifications for Lift Truck Models ERP16-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), ESC030-40AC (B883),ESC030-40AD (C883) 1546

Tilt Cylinders 1546

Main and Free-Lift Cylinders 1546

Sideshift Cylinder 1547

Fork Positioner Cylinder 1547

Torque Specifications for Lift Truck Model ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 1547

Tilt Cylinders 1547

Main and Free-Lift Cylinder 1547

Sideshift Cylinder 1547

Torque Specifications for Lift Truck Model ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 1547

Tilt Cylinder 1548

Main and Free Lift Cylinder 1548

Sideshift Cylinder 1548

524319496-2100YRM1382-(07-2023)-UK-EN 1551

Safety Procedures When Working Near Mast 1561

General 1564

Description 1564

Tilt Cylinder Repair for 2 0-5 5T Trucks 1565

Remove 1565

Disassemble 1567

Inspect 1568

Clean 1568

Assemble 1568

Install 1570

Tilt Cylinders, Adjust 1570

Tilt Cylinder Leak Check 1573

Tilt Cylinder Repair

for 1 0-2 0T Trucks 1574

Remove 1574

Disassemble 1577

Inspect 1579

Clean 1579

Assemble 1579

Install 1579

Tilt Cylinders, Adjust 1580

Tilt Cylinders Leak Check 1581

Lift Cylinder Repair

for 2 0-3 5T Trucks 1583

Main Lift Cylinders 1583

Remove 1583

Two-Stage FFL 1583

Three-Stage FFL 1585

Four-Stage FFL 1585

Two-Stage LFL 1586

Disassemble 1586

Two-Stage FFL 1586

Three-Stage FFL 1588

Four-Stage FFL 1590

Two-Stage LFL 1591

Clean 1592

Inspect 1592

Assemble 1592

Two-Stage FFL 1592

Three-Stage FFL 1593

Four-Stage FFL 1593

Two-Stage LFL 1594

Install 1594

Two-Stage FFL 1594

System Air Bleed Procedures 1594

Three-Stage FFL 1595

Four-Stage FFL 1595

Two-Stage LFL 1596

Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 1597

Main Lift Cylinder 1597

Remove 1597

Main Lift Cylinders – Two-Stage FFL Mast 1597

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 1599

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 1603

Main Lift Cylinder – Two-Stage LFL Mast 1603

Disassemble 1606

Main Lift Cylinders – Two-Stage FFL Mast 1606

Main Lift Cylinder – Three-Stage FFL Mast 1608

Main Lift Cylinder – Two-Stage LFL Mast 1609

Clean 1610

Inspect 1610

Assemble 1610

Main Lift Cylinder – Two-Stage FFL Mast 1610

Main Lift Cylinder – Three-Stage FFL Mast 1611

Main Lift Cylinder – Two-Stage LFL Mast 1611

Install 1611

Main Lift Cylinder – Two-Stage FFL Mast 1611

Left-Hand Main Lift Cylinder – Three-Stage FFL Mast 1612

Right-Hand Main Lift Cylinder – Three-Stage FFL Mast 1613

Main Lift Cylinder – Two-Stage LFL Mast 1614

System Air Bleed Procedures 1614

All Main Lift Cylinders 1615

Lift Cylinder Repair for 1 5-2 0T Trucks 1616

Main Lift Cylinder 1616

Remove 1616

Two-Stage FFL 1616

Three-Stage FFL 1616

Two-Stage LFL 1617

Four-Stage FFL 1619

Disassemble 1621

Two-Stage FFL 1621

Three-Stage FFL 1622

Two-Stage LFL 1623

Four-Stage FFL 1624

Clean 1626

Inspect 1627

Assemble 1627

Two-Stage FFL 1627

Three-Stage FFL 1627

Two-Stage LFL 1628

Four-Stage FFL 1628

Install 1629

Two-Stage FFL 1629

System Air Bleed Procedures 1630

Three-Stage FFL Mast 1630

Two-Stage LFL 1630

Four-Stage FFL 1631

Mast and Carriage Install for Two-Stage FFL, Three-Stage FFL, and Two-Stage LFL 1631

Mast and Carriage Installation for Four-Stage FFL 1632

Lift Cylinder Repair for 4 0-5 5T Trucks 1633

Main Lift Cylinders 1633

Remove 1633

Two-Stage FFL 1633

Three-Stage FFL 1635

Two-Stage LFL 1635

Disassemble 1636

Two-Stage FFL 1636

Three-Stage FFL 1638

Two-Stage LFL 1639

Clean 1640

Inspect 1640

Assemble 1640

Two-Stage FFL 1640

Three-Stage FFL 1641

Two-Stage LFL 1641

Install 1642

Two-Stage FFL 1642

System Air Bleed Procedures 1642

Three-Stage FFL 1642

Two-Stage LFL 1643

Free-Lift Cylinder Repair for 2 0-3 5T Trucks 1644

Free-Lift Cylinder 1644

Remove 1644

Two and Three-Stage FFL Mast 1644

Four-Stage FFL For Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1645

Disassemble 1647

Two and Three-Stage FFL Mast 1647

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1648

Clean 1648

Inspect 1649

Assemble 1649

Two and Three-Stage FFL Mast 1649

Four-Stage FFL Mast for Lift Truck ERC22-356VG (ERC045-070VG) (A968) 1649

Install 1650

Two and Three-Stage FFL Mast 1650

Four-Stage FFL Mast for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 1650

Free Lift Cylinder Repair for Lift Truck Model ERP15VT (G807) 1652

Free-Lift Cylinder 1652

Remove 1652

Three-Stage FFL Mast 1652

Disassemble 1654

Clean 1655

Inspect 1655

Assemble 1655

Install 1655

Free Lift Cylinder Repair for 1 5-2 0T Trucks 1657

Free-Lift Cylinder 1657

Remove 1657

Two and Three-Stage FFL Mast 1657

Four-Stage FFL Mast 1659

Disassemble 1662

Two-Stage and Three-Stage FFL Masts 1662

Four Stage FFL Mast 1662

Clean 1663

Inspect 1663

Assemble 1663

Two-Stage and Three-Stage FFL Masts 1663

Four-Stage FFL Mast 1664

Install 1664

Two-Stage and Three-Stage FFL Masts 1664

Four-Stage FFL Mast 1665

All Masts 1668

Free-Lift Cylinder Repair

for 4 0-5 5T Trucks 1669

Free-Lift Cylinder 1669

Remove 1669

Two and Three-Stage FFL Mast 1669

Disassemble 1670

Two and Three-Stage FFL Mast 1670

Clean 1671

Inspect 1671

Assemble 1671

Two and Three-Stage FFL Mast 1671

Install 1672

Two and Three-Stage FFL Mast 1672

Sideshift Cylinder Repair

for 1 5-3 5T Trucks Prior to December 2016 1673

Remove 1673

Disassemble 1676

Clean and Inspect 1678

Assemble and Install 1678

Sideshift Cylinder Repair

for 1 5-3 5T Trucks After December 2016 1680

Remove 1680

Disassemble 1683

Clean and Inspect 1684

Assemble and Install 1685

Integral Side-Shift Cylinder Gland Leak Checks 1687

Sideshift Cylinder Repair

for 4 0-5 5T Trucks 1688

Remove 1688

Disassemble 1689

Clean and Inspect 1690

Assemble and Install 1690

Fork Positioner Cylinder Repair Prior to December 2016 1691

Remove 1691

Disassemble 1691

Clean 1694

Inspect 1694

Assemble 1695

Install 1695

Fork Positioner Cylinder Adjustment 1695

Fork Positioner Cylinder Repair After December 2016 1697

Remove 1697

Disassemble 1697

Clean 1700

Inspect 1700

Assemble 1701

Install 1701

Fork Positioner Cylinder Adjustment 1701

Lift Cylinder Leak Check 1703

Seal Kit Installation 1704

External Installation (Seal and Back-Up Ring) 1704

Internal Installation (Piston Rod Assembly) 1704

Torque Specifications for Lift Truck Models ERC22-35VG (ERC045-070VG) (A968) and ERP22-25VL (ERP045-070VL) (A976) 1705

Tilt Cylinders 1705

Piston Rod Nut 1705

Gland 1705

Tilt Cylinder Mounting Capscrew 1705

Tilt Cylinder Rod End Capscrew 1705

Main and Free-Lift Cylinder 1705

Sideshift Cylinder 1705

Fork Positioner Cylinder 1705

Torque Specifications for Lift Truck Model ERP15VT (G807) 1706

Tilt Cylinders 1706

Main and Free-Lift Cylinders 1706

Sideshift Cylinder 1706

Torque Specifications for Lift Truck Models ERP16-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), ESC030-40AC (B883),ESC030-40AD (C883) 1707

Tilt Cylinders 1707

Main and Free-Lift Cylinders 1707

Sideshift Cylinder 1707

Fork Positioner Cylinder 1707

Torque Specifications for Lift Truck Model ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 1708

Tilt Cylinders 1708

Main and Free-Lift Cylinder 1708

Sideshift Cylinder 1708

Torque Specifications for Lift Truck Model ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 1708

Tilt Cylinder 1708

Main and Free Lift Cylinder 1708

Sideshift Cylinder 1708

524319497-2200YRM1335-(01-2023)-UK-EN 1711

General 1719

Description 1719

Display Panel Menu Access 1719

Menu Flowchart 1720

Supervisor Menu Flowchart 1720

Menu Navigation 1726

Icon Glossary 1730

Introduction 1730

Soft Key Icons 1730

Overlay Icons 1731

Icons on System Off Screen and Alert Screens 1731

Main Menu Title Screens 1735

Submenu Icons Grouped by Menu 1737

Operating Screen Icons 1737

Password Screen Icons 1738

Activity Log Submenu Icons 1738

Calibration Submenu Icons 1740

Display Submenu Icons 1742

Status Submenu Icons 1744

Truck Setup Submenu Icons 1747

Operating Screen 1754

Introduction 1754

Performance Mode Controls 1755

Status and Warning Icons 1755

Battery Discharge Indicator 1756

Direction and Parking Brake Indicators 1757

Hazard Flashers and Lighting Controls 1757

Steer Angle Indicator 1757

System Time 1757

Load Weight Indicator 1757

System Off/Alert Screens 1758

Introduction 1758

System Off Screen 1758

Alert Screens 1758

Password Screen 1760

Introduction 1760

Password Screen 1760

Service Technician Password Setup 1760

Adding/Removing/Changing Passwords 1761

Password Log 1764

Activity Log Menu 1765

Introduction 1765

Operator Checklist Log 1766

Password Log 1769

Impact Events Log 1771

Calibration Menu 1773

Introduction 1773

Load Weight Calibration 1773

Return to Set Tilt Stop Point Calibration 1774

E-Hydraulic and Manual Valve Threshold Calibration 1774

Steering Wheel Center Point Calibration 1775

Steer Axle Position Calibration 1775

Steer Axle Center Point Calibration 1776

Manual Hydraulics Calibration 1777

Display Menu 1778

Introduction 1778

Set Date and Time Format Menu 1778

Set Daylight Saving Time Menu 1779

Procedure for Setting Up Automatic Daylight Savings Time 1780

Set Time and Date Menu 1782

Procedure for Setting Time and Date 1782

Set Units Menu 1783

Status Menu 1784

Introduction 1784

VSM Versions 1784

Display Versions 1785

Truck Serial Number 1785

Hour Meters 1785

E-Hydraulic Controller Versions 1785

Pump Motor Controller Versions 1785

Traction Motor Controller 1 Versions 1785

Traction Motor Controller 2 Versions 1786

Light Controller Versions 1786

Impact Sensor Versions 1786

Truck Setup Menu 1787

Introduction 1787

Add/Remove Password 1787

Battery Settings 1787

Restore Default Settings 1788

Motion Alarm 1788

Impact Monitor Settings 1789

Impact Detection 1789

Setting Adjustments 1789

Initial Adjustment of Soft and Hard Impact Settings 1789

Readjustment of Soft and Hard Impact Settings 1789

Auto Power-Off Time Delay 1790

Return to Set Tilt 1790

Traction Speed Limit 1790

Scheduled Maintenance Reminder 1791

Minimum Pump Standby Flow Rate 1792

Operator Checklist 1792

Impact Monitor Shutdown 1793

Motor Braking 1794

Changing the Motor Braking Settings 1794

Steering Wheel Friction and Steering Turns Adjustment 1795

How to Adjust Settings 1795

Steering Friction Setting 1795

Steering Wheel Number of Turns 1796

524319497-2200YRM1335-(07-2020)-UK-EN 1799

General 1805

Description 1805

Display Panel Menu Access 1805

Menu Flowchart 1806

Supervisor Menu Flowchart 1806

Menu Navigation 1812

Icon Glossary 1816

Introduction 1816

Soft Key Icons 1816

Overlay Icons 1817

Icons on System Off Screen and Alert Screens 1817

Main Menu Title Screens 1821

Submenu Icons Grouped by Menu 1823

Operating Screen Icons 1823

Password Screen Icons 1824

Activity Log Submenu Icons 1824

Calibration Submenu Icons 1826

Display Submenu Icons 1828

Status Submenu Icons 1830

Truck Setup Submenu Icons 1833

Operating Screen 1840

Introduction 1840

Performance Mode Controls 1840

Status and Warning Icons 1841

Battery Discharge Indicator 1842

Direction and Parking Brake Indicators 1842

Hazard Flashers and Lighting Controls 1843

Steer Angle Indicator 1843

System Time 1843

Load Weight Indicator 1843

System Off/Alert Screens 1844

Introduction 1844

System Off Screen 1844

Alert Screens 1844

Password Screen 1846

Introduction 1846

Password Screen 1846

Service Technician Password Setup 1846

Adding/Removing/Changing Passwords 1847

Password Log 1850

Activity Log Menu 1851

Introduction 1851

Operator Checklist Log 1851

Password Log 1853

Impact Events Log 1855

Calibration Menu 1857

Introduction 1857

Load Weight Calibration 1857

Return to Set Tilt Stop Point Calibration 1858

E-Hydraulic and Manual Valve Threshold Calibration 1858

Steering Wheel Center Point Calibration 1859

Steer Axle Position Calibration 1859

Steer Axle Center Point Calibration 1860

Manual Hydraulics Calibration 1861

Display Menu 1862

Introduction 1862

Set Date and Time Format Menu 1862

Set Daylight Saving Time Menu 1863

Procedure for Setting Up Automatic Daylight Savings Time 1864

Set Time and Date Menu 1866

Procedure for Setting Time and Date 1866

Set Units Menu 1867

Status Menu 1868

Introduction 1868

VSM Versions 1868

Display Versions 1869

Truck Serial Number 1869

Hour Meters 1869

E-Hydraulic Controller Versions 1869

Pump Motor Controller Versions 1869

Traction Motor Controller 1 Versions 1869

Traction Motor Controller 2 Versions 1870

Light Controller Versions 1870

Impact Sensor Versions 1870

Truck Setup Menu 1871

Introduction 1871

Add/Remove Password 1871

Battery Settings 1871

Restore Default Settings 1872

Motion Alarm 1872

Impact Monitor Settings 1872

Impact Detection 1873

Setting Adjustments 1873

Initial Adjustment of Soft and Hard Impact Settings 1873

Readjustment of Soft and Hard Impact Settings 1873

Auto Power-Off Time Delay 1874

Return to Set Tilt 1874

Traction Speed Limit 1874

Scheduled Maintenance Reminder 1875

Minimum Pump Standby Flow Rate 1876

Operator Checklist 1876

Impact Monitor Shutdown 1877

Motor Braking 1878

Changing the Motor Braking Settings 1878

Steering Wheel Friction and Steering Turns Adjustment 1879

How to Adjust Settings 1879

Steering Friction Setting 1879

Steering Wheel Number of Turns 1880

524319498-2200YRM1336-(02-2023)-UK-EN 1883

General 1891

Description 1891

Display Panel Menu Access 1891

Menu Flowchart 1892

Technician Menu Flowchart 1892

Menu Navigation 1898

Icon Glossary 1902

Introduction 1902

Soft Key Icons 1902

Overlay Icons 1903

Heat Exchange Module Warning Indicator Screen 1903

System Off Screen and Alert Screens 1904

Main Menu Title Screens 1910

Submenu Icons Grouped by Menu 1911

Operating Screen Icons 1911

Password Screen Icons 1913

Activity Log Submenu Icons 1913

Calibration Submenu Icons 1914

Display Submenu Icons 1918

Status Submenu Icons 1920

Truck Setup Submenu Icons 1923

Diagnostics Submenu Icons 1935

Operating Screen 1945

Introduction 1945

Performance Mode Controls 1945

Status and Warning Icons 1946

Battery Discharge Indicator 1947

Direction and Parking Brake Indicators 1947

Hazard Flashers and Lighting Controls 1948

Steer Angle Indicator 1948

System Time 1948

Load Weight Indicator 1948

System Off/Alert Screens 1949

Introduction 1949

System Off Screen 1949

Alert Screens 1949

Password Screen 1951

Introduction 1951

Password Screen 1951

Service Technician Password Setup 1951

Adding/Removing/Changing Passwords 1952

Password Log 1955

Activity Log Menu 1956

Introduction 1956

Operator Checklist Log 1956

Password Log 1958

Impact Events Log 1960

Calibration Menu 1962

Introduction 1962

Load Weight Calibration 1962

Return to Set Tilt Stop Point Calibration 1963

E-Hydraulic and Manual Valve Threshold Calibration 1963

Steering Wheel Center Point Calibration 1964

Steer Axle Position Calibration 1965

Steer Axle Center Point Calibration 1966

Manual Hydraulics Calibration 1966

Display Menu 1967

Introduction 1967

Set Date and Time Format Menu 1967

Set Daylight Saving Time Menu 1968

Procedure for Setting Up Automatic Daylight Savings Time 1969

Set Time and Date Menu 1971

Procedure for Setting Time and Date 1971

Set Units Menu 1972

Status Menu 1973

Introduction 1973

VSM Versions 1973

Display Versions 1974

Truck Serial Number 1974

Hour Meters 1974

E-Hydraulic Controller Versions 1974

Pump Motor Controller Versions 1974

Traction Motor Controller 1 Versions 1974

Traction Motor Controller 2 Versions 1975

Light Controller Versions 1975

Impact Sensor Versions 1975

E-Steer Controller 1 Versions 1975

E-Steer Controller 2 Versions 1975

Truck Setup Menu 1976

Introduction 1976

Add/Remove Password 1977

Battery Settings 1977

Motor Braking 1977

Changing the Motor Braking Settings 1978

Battery Mode 1978

Battery Setup 1979

BDI Adjustment Setting 1980

Acceleration Rates 1981

Hour Meter Initialization 1982

Impact Monitor Shutdown 1982

Operator Checklist 1984

Minimum Pump Standby Flow Rate 1984

Scheduled Maintenance Reminder 1985

Traction Speed Limit 1986

Return to Set Tilt 1986

Auto Power-Off Time Delay 1987

Impact Monitor Settings 1987

Impact Detection 1988

Setting Adjustments 1988

Initial Adjustment of Soft and Hard Impact Settings 1988

Readjustment of Soft and Hard Impact Settings 1988

Motion Alarm 1988

Lift Hydraulic Function Maximum Speed and Ramp Times 1989

Lower Hydraulic Function Maximum Speed and Ramp Times 1989

Tilt Forward Hydraulic Function Maximum Speed and Ramp Times 1990

Tilt Backward Hydraulic Function Maximum Speed and Ramp Times 1990

Auxiliary 1A Hydraulic Function Maximum Speed and Ramp Times 1990

Auxiliary 1B Hydraulic Function Maximum Speed and Ramp Times 1990

Auxiliary 2A Hydraulic Function Maximum Speed and Ramp Times 1990

Auxiliary 2B Hydraulic Function Maximum Speed and Ramp Times 1990

Optional Hydraulic Functions 1990

Rear Lights Control 1991

Restore Default Settings 1991

Steering Wheel Friction and Steering Turns Adjustment 1992

Navigation 1993

How to Adjust Settings 1993

Steering Friction 1993

Steering Wheel Number of Turns 1994

Diagnostics Menu 1996

Introduction 1996

Fault Code Log 1996

Fault Log Details 1997

Speedometer 1998

Direction Switch 1998

Traction Motor 1 Status 1999

Traction Motor 2 Status 1999

Occupancy Sensor 1999

Brake System Sensors 1999

Pump Status 2000

Hydraulic Control Inputs 2001

E-Hydraulic Valves 2001

Hydraulic Sensors 2002

System Voltages 2002

Steering Position Sensors 2004

E-Steering Position Sensors 2004

Electric Brake 2005

Navigation 2006

ESS Diagnostics Menus A, B, and C 2007

Menu A 2007

Menu B 2008

Menu C 2010

524319498-2200YRM1336-(07-2020)-UK-EN 2013

General 2019

Description 2019

Display Panel Menu Access 2019

Menu Flowchart 2020

Technician Menu Flowchart 2020

Menu Navigation 2026

Icon Glossary 2030

Introduction 2030

Soft Key Icons 2030

Overlay Icons 2031

Heat Exchange Module Warning Indicator Screen 2031

System Off Screen and Alert Screens 2032

Main Menu Title Screens 2037

Submenu Icons Grouped by Menu 2039

Operating Screen Icons 2039

Password Screen Icons 2040

Activity Log Submenu Icons 2040

Calibration Submenu Icons 2042

Display Submenu Icons 2045

Status Submenu Icons 2047

Truck Setup Submenu Icons 2051

Diagnostics Submenu Icons 2062

Operating Screen 2072

Introduction 2072

Performance Mode Controls 2072

Status and Warning Icons 2073

Battery Discharge Indicator 2074

Direction and Parking Brake Indicators 2075

Hazard Flashers and Lighting Controls 2075

Steer Angle Indicator 2075

System Time 2075

Load Weight Indicator 2075

System Off/Alert Screens 2076

Introduction 2076

System Off Screen 2076

Alert Screens 2076

Password Screen 2078

Introduction 2078

Password Screen 2078

Service Technician Password Setup 2078

Adding/Removing/Changing Passwords 2079

Password Log 2081

Activity Log Menu 2082

Introduction 2082

Operator Checklist Log 2082

Password Log 2084

Impact Events Log 2086

Calibration Menu 2088

Introduction 2088

Load Weight Calibration 2088

Return to Set Tilt Stop Point Calibration 2089

E-Hydraulic and Manual Valve Threshold Calibration 2089

Steering Wheel Center Point Calibration 2090

Steer Axle Position Calibration 2091

Steer Axle Center Point Calibration 2091

Manual Hydraulics Calibration 2092

Display Menu 2093

Introduction 2093

Set Date and Time Format Menu 2093

Set Daylight Saving Time Menu 2094

Procedure for Setting Up Automatic Daylight Savings Time 2095

Set Time and Date Menu 2097

Procedure for Setting Time and Date 2097

Set Units Menu 2098

Status Menu 2099

Introduction 2099

VSM Versions 2099

Display Versions 2100

Truck Serial Number 2100

Hour Meters 2100

E-Hydraulic Controller Versions 2100

Pump Motor Controller Versions 2100

Traction Motor Controller 1 Versions 2100

Traction Motor Controller 2 Versions 2101

Light Controller Versions 2101

Impact Sensor Versions 2101

E-Steer Controller 1 Versions 2101

E-Steer Controller 2 Versions 2101

Truck Setup Menu 2102

Introduction 2102

Add/Remove Password 2103

Battery Settings 2103

Motor Braking 2103

Changing the Motor Braking Settings 2104

Battery Mode 2104

Battery Setup 2105

BDI Adjustment Setting 2106

Acceleration Rates 2107

Hour Meter Initialization 2108

Impact Monitor Shutdown 2108

Operator Checklist 2109

Minimum Pump Standby Flow Rate 2110

Scheduled Maintenance Reminder 2110

Traction Speed Limit 2112

Return to Set Tilt 2112

Auto Power-Off Time Delay 2112

Impact Monitor Settings 2113

Impact Detection 2113

Setting Adjustments 2113

Initial Adjustment of Soft and Hard Impact Settings 2113

Readjustment of Soft and Hard Impact Settings 2114

Motion Alarm 2114

Lift Hydraulic Function Maximum Speed and Ramp Times 2114

Lower Hydraulic Function Maximum Speed and Ramp Times 2115

Tilt Forward Hydraulic Function Maximum Speed and Ramp Times 2115

Tilt Backward Hydraulic Function Maximum Speed and Ramp Times 2115

Auxiliary 1A Hydraulic Function Maximum Speed and Ramp Times 2115

Auxiliary 1B Hydraulic Function Maximum Speed and Ramp Times 2116

Auxiliary 2A Hydraulic Function Maximum Speed and Ramp Times 2116

Auxiliary 2B Hydraulic Function Maximum Speed and Ramp Times 2116

Optional Hydraulic Functions 2116

Rear Lights Control 2116

Restore Default Settings 2117

Steering Wheel Friction and Steering Turns Adjustment 2117

Navigation 2118

How to Adjust Settings 2118

Steering Friction 2118

Steering Wheel Number of Turns 2119

Diagnostics Menu 2121

Introduction 2121

Fault Code Log 2121

Fault Log Details 2122

Speedometer 2123

Direction Switch 2123

Traction Motor 1 Status 2123

Traction Motor 2 Status 2124

Occupancy Sensor 2124

Brake System Sensors 2124

Pump Status 2125

Hydraulic Control Inputs 2125

E-Hydraulic Valves 2125

Hydraulic Sensors 2126

System Voltages 2126

Steering Position Sensors 2127

E-Steering Position Sensors 2127

Electric Brake 2128

Navigation 2129

524319503-8000YRM1341-(10-2015)-UK-EN 2131

524319504-9000YRM1377-(09-2019)-UK-EN 2171

SECTION 9010 Operational Diagnostic Procedures 2187

Group 05 – Operational Checkout 2189

SECTION 9025 Traction Motor 2199

Group 10 – Principles of Operation 2201

Group 30 – Observed Symptoms 2207

SECTION 9030 Electrical System 2209

Group 03 – General Maintenance and Diagnostic Data 2219

Group 10 – Principles of Operation 2263

Group 20 – Diagnostic Trouble Codes 2295

Group 30 – Observed Symptoms 2907

Group 55 – Icons and Graphics 2951

SECTION 9035 Drive Axle/Unit 2959

Group 10 – Principles of Operation 2961

Group 30 – Observed Symptoms 2971

Group 20 – Diagnostic Trouble Codes 2983

SECTION 9050 Hydraulic Systems 2985

Group 10 – Principles of Operation 2989

Group 33 – Observed Symptoms-Gear Pump 3027

Group 43 – Tests and Adjustments-Gear Pump 3107

SECTION 9060 Operators Station 3137

Group 10 – Principles of Operation 3139

SECTION 9070 Front End (Mast) and Chassis 3179

Group 10 – Principles of Operation 3181

Group 30 – Observed Symptoms 3199

SECTION 9080 Supplementary Data 3243

Group 50 – Abbreviations and Acronyms 3245

524320282-2200YRM1337-(01-2020)-UK-EN 3253

General 3261

Discharging the Capacitors 3262

Display Panel and Key or Keyless Switch Replacement 3262

Display Panel, Replace 3262

Remove 3262

Install 3265

Electronic and Manual Hydraulic Controls 3268

General 3268

Manual Hydraulic Controls 3269

Upper Front Cover 3269

Direction Control Switch 3269

Remove 3269

Install 3272

Clamp Button 3272

Remove 3272

Install 3272

Return To Set Tilt (RTST) Button 3272

Remove 3272

Install 3272

Emergency Disconnect Switch 3273

Remove 3273

Install 3273

E-Hydraulic Controls – Test 3274

Mini-Levers 3274

Full Stroke Test 3274

Function Returns to Neutral Test 3274

Push (Override) Button 3275

E-Hydraulic Controls 3275

Mini-levers, Remove and Install 3275

Armrest Assembly 3276

Remove 3276

Install 3278

Horn Button 3278

Remove 3278

Install 3279

Direction Control Switch 3279

Remove 3279

Install 3280

Emergency Disconnect Switch 3280

Remove 3281

Install 3281

Push (Override) Buttons and Function Selection Button 3281

Remove 3282

Install 3284

Electronic-Hydraulic Controls, After January, 2020 3284

General 3284

E-Hydraulic Controls – TEST 3285

Mini-Levers 3285

Full Stroke Test 3286

Function Returns to Neutral Test 3286

Push Button (push (override) button) 3286

Mini-levers, Remove and Install 3287

Armrest Assembly 3287

Remove 3287

Install 3290

Horn Button 3290

Remove 3290

Install 3290

Direction Control Switch 3291

Remove 3291

Install 3291

Emergency Disconnect Switch 3291

Remove 3292

Install 3292

Push (Override) Buttons 3293

Remove 3293

Install 3294

Sensors and Switches 3295

General 3295

Synchronous Steering Valve 3295

Steering Axle Sensor 3295

Lift Truck Models ERP15-20VT (G807) Manufactured Before November, 2014 and ERP030-040VT (G807) 3295

Remove 3295

Install 3299

Lift Truck Models ERP15-20VT (G807) Manufactured After November, 2014 3299

Remove 3299

Install 3300

Lift Truck Models ERP16-20VF (ERP30-40VF) (A955) 3301

Remove 3301

Install 3302

Hydraulic Motor Speed Sensor 3303

Remove 3303

Install 3303

Hydraulic Motor Temperature Sensor 3304

Transmission Speed Sensor 3304

Remove 3304

Install 3306

Traction Motor Temperature Sensor 3307

Tilt Position Sensor 3307

Remove 3307

Install 3307

Low Level Brake Fluid Switch 3308

Remove 3308

Install 3310

Service Brake Pressure Sensor, Lift truck models , and , manufactured before February, 2016ERP030-040VT (G807)ERP30-40VF (A955) ERP15-20VT (G807)ERP16-20VF (A955) 3310

Remove 3310

Install 3310

Service Brake Pressure Sensor, Lift Truck Models and Manufactured After February, 2016ERP15-20VT (G807) ERP16-20VF (A955) 3310

Remove 3310

Install 3311

Accelerator Pedal Position Sensor 3312

Remove 3312

Install 3314

Seat Belt Sequence Module 3314

Remove 3314

Install 3314

Seat Sensor (Operator Presence System) 3315

Non-Suspension Seat 3315

Remove 3315

Install 3315

Full Suspension and Swivel Seats 3316

Remove 3316

Install 3316

Steering Wheel Position Sensor 3316

Remove 3316

Install 3319

Load Weight Sensor 3319

Remove 3319

Install 3320

Battery Gate Switch 3320

Remove, for Lift Truck Models, and, Manufactured Before December, 2015ERP15-20VT (G807)ERP16-20VF (A955)ERP030-040VT (G807)ERP030-040VF (A955) 3320

Install, for Lift Truck Models, and, Manufactured Before December, 2015ERP15-20VT (G807)ERP16-20VF (A955)ERP030-040VT (G807)ERP030-040VF (A955) 3322

Remove, for Lift Truck Models and Manufactured After December, 2015ERP030-040VT (G807) ERP030-040VF (A955) 3323

Install, for Lift Truck Models and Manufactured After December, 2015ERP030-040VT (G807) ERP030-040VF (A955) 3324

Horn Switch 3325

Remove 3325

Install 3326

Rear Horn Button Switch 3326

Remove 3326

Install 3327

Impact Sensor 3327

Remove 3327

Install 3328

Steering Motor Speed Sensor 3328

Remove 3328

Install 3329

Hydraulic Tank Level Sensor 3330

Remove 3330

Install 3330

Hydraulic Filter Pressure Switch 3332

Remove 3332

Install 3332

Hydraulic Oil Temperature Sensor 3332

Remove 3332

Install 3332

Motor Controllers Replacement 3333

General 3333

Hydraulic Pump and Motor Controller, Lift Truck Models Manufactured Before November, 2014 and and ERP15-20VT (G807) ERP030-040VT (G807) ERP16-20VF (ERP30-40VF) (A955) 3333

Remove 3333

Fan, Remove 3336

Fan, Install 3338

Install 3338

Hydraulic Pump and Motor Controller, Lift Truck Models Manufactured After November, 2014ERP15-20VT (G807) 3338

Remove 3338

Fan, Remove 3339

Fan, Install 3339

Install 3340

Traction Motor Controllers 3340

Remove 3340

Fan, Remove 3344

Fan, Install 3345

Install 3346

Line Contactor, Lift Truck Models ERP15-20VT (G807) Manufactured Before November, 2014, ERP030-040VT (G807), and ERP16-20VF (ERP30-40VF) (A955) 3346

Remove 3346

Install 3348

Line Contactor, Lift Truck Models Manufactured After November, 2014ERP15-20VT (G807) 3348

Remove 3348

Install 3349

Steering Motor Controller 3349

Remove 3349

Install 3350

Vehicle Systems Manager 3351

General 3351

Remove 3351

Install 3352

Programming a New VSM and/or Display Panel 3353

PC Service Tool Software 3353

Fuses 3354

Audible Alarm 3358

Battery Connection 3359

Inspect 3359

Replacing Cables 3359

Cab Heater 3361

Lights 3361

General 3361

Work Lights (Front and Rear) 3363

Halogen Bulb Lights 3363

Remove 3363

Install 3363

LED Lights 3363

Remove 3363

Install 3364

Strobe Light 3364

Remove 3364

Install 3365

LED Tail, Backup, and Brake Lights 3365

Remove 3365

Install 3366

Front Marker/Turn Signal Lights 3366

Remove 3366

Install 3368

Converter 3368

Remove 3368

Install 3368

524320287-8000YRM1339-(01-2018)-UK-EN 3371

Introduction 3377

General 3377

Serial Number 3378

Discharging the Capacitors 3378

Rapid Charge 3378

How to Tow a Disabled Lift Truck 3379

How to Put Lift Truck on Blocks 3380

How to Raise Drive Tires 3380

How to Raise Steer Tires 3381

How to Clean a Lift Truck 3382

Safety Procedures When Working Near Mast 3382

WHEN WORKING NEAR THE MAST ALWAYS: 3383

Maintenance Schedule 3385

Maintenance Procedures Every 8 Hours or Daily 3390

How to Make Checks With the Key or Keyless Switch OFF 3390

Wheels and Tires 3390

Safety Labels 3390

Frame and Covers 3390

Forks 3392

General 3392

Inspect 3392

Remove 3393

Install 3396

Adjust 3396

Inspection of Mast, Carriage, Header Hoses, Lift Chains, and Attachments 3397

Hydraulic Oil Level and Leaks 3398

Operator Restraint System 3398

Emergency Locking Retractor (ELR) 3399

Seat Adjustments 3400

Seat Position Adjustment (Swivel Seat) 3400

Seat Adjustment for Operator Weight 3400

Battery Restraint System 3402

Steering Column Adjustments 3408

Tilt Adjust Feature 3408

Tilt Memory Feature 3408

Telescopic Feature 3408

Battery Check 3408

How to Make Checks With the Key or Keyless Switch ON 3409

Control Levers and Pedals 3409

Direction and Speed Controls 3409

Electrical Components 3409

Steering System 3410

Hydraulic System 3410

Service Brakes 3411

Automatic Parking Brake 3411

Operator Presence System 3411

Oil Leaks 3412

Maintenance Procedures After First 100 Hours or 2 Months of Service 3412

Tire and Wheel Assemblies 3412

Mast Sliding Surfaces 3412

Mast Pivot Pins and Mounting Hardware 3413

Fork Guides and Pins 3414

Integral Sideshift Carriage 3414

Check Upper and Lower Bearings 3414

Header Hoses, Hose Fittings, and Clamps 3416

Maintenance Procedures Every 500 Hours or Three Months 3416

Tire and Wheel Assemblies 3416

Forks, Inspect 3417

Mast and Carriage 3418

Mast Sliding Surfaces 3418

Mast Pivot Pins, Bushings, and Mounting Hardware 3419

Header Hoses 3419

Fourth Function Mini Rollers Lubrication 3420

Lift Chain Lubrication 3421

Lift Chain Wear Check 3421

Integral Sideshift Carriage 3422

Check Upper and Lower Bearings 3422

Fork Positioner 3423

Fork Guides and Pins 3424

Check Lower Mounting Hook 3424

Tilt Cylinder Rod End Pins 3425

Control Levers, Pedals, and Hinges 3425

Direction and Speed Control Pedals 3425

Hydraulic Hoses, Fittings, and Clamps 3425

Hydraulic Breather Cap 3426

Service Brakes 3426

Master Cylinder Oil Check 3426

Parking Brake 3427

Manual Override Handle 3427

Electrical Inspection 3428

Contactors 3428

Maintenance Procedures Every 2000 Hours or Yearly 3428

Hydraulic System 3429

Hydraulic Oil Filter, Change 3429

Hydraulic Breather, Check 3431

Steering Axle 3432

Steering Actuator and Steering Plate Torque Check 3432

Transaxle Oil Change 3432

Transaxle Breather Check 3434

Brake Oil Change 3434

Forks, Inspect 3434

Integral Sideshift Carriage 3435

Lift Chains 3435

Maintenance Procedures Every 4000 Hours or Two Years 3436

Hydraulic Oil Change 3436

Steering Wheel Position Sensor Inspection 3438

Fixed Steering Column 3438

Telescopic Steering Column 3439

Telescopic Steering Column Lubrication 3440

Welding Repairs 3441

Lift and Tilt System Leak Check 3441

Lift Cylinders Leak Check 3442

Tilt Cylinder Leak Check 3442

Battery Maintenance 3442

How to Charge Battery 3442

Rapid Charge 3444

How to Change Battery 3444

Remove the Battery 3444

Install the Battery 3446

Optional Side Removal of Battery 3448

Battery Size Specifications 3448

Wheels and Tires 3448

General 3449

Pneumatic Tires Repair 3449

Remove Wheels From Lift Truck 3449

Remove Tire From Wheel 3450

Install Wheel in Tire 3453

Add Air to Tires 3456

Wheels, Install 3456

Solid Rubber Tires on Pneumatic Wheels, Change 3456

Install the Wheels 3460

Solid Rubber (Cushioned) Tire Repair 3460

Remove Wheels From Lift Truck 3460

Remove and Install Tire on Wheel 3460

Lift Chain Adjustments 3461

524327049-0620YRM1385-(02-2023)-UK-EN 3465

General 3473

Discharging the Capacitors for Lift Truck Models ESC030-040AC (B883), ESC030-040AD (C883) 3479

Discharging the Capacitors (All Other Models) 3481

Traction Motor Repair 3482

For Lift Truck Models , and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955), ESC030-040AC (B883) 3482

Remove 3482

Disassemble 3483

Electrical Connector Repair or Replacement 3485

Clean 3485

Inspect 3485

Assemble 3486

Install 3488

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) and ERC16-20VA (ERC030-040VA) (A969) 3490

Remove 3490

Disassemble 3490

Electrical Connector Repair or Replacement 3493

Clean 3493

Inspect 3493

Assemble 3494

Install 3494

For Lift Truck ERP2 2-3 5VL (ERP045-070VL) (A976) 3494

Remove 3494

Disassemble 3494

Clean 3496

Inspect 3496

Assemble 3497

Install 3497

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080120VM, ERP100VML) (A985) 3497

Remove 3497

Clean 3499

Install 3499

For Lift Truck ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3499

Remove 3499

Disassemble 3499

Electrical Connector Repair or Replacement 3501

Clean 3501

Inspect 3501

Assemble 3502

Install 3503

Traction Motor Repair for 4-5 5T Lift Trucks 3504

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080120VM, ERP100VML) (A985) 3504

Remove 3504

Clean 3506

Install 3506

Hydraulic Motor Repair 3507

For Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955)ESC030-040AC (B883), ESC030-040AD (C883) 3507

Remove 3507

Disassemble 3508

Electrical Connector Repair or Replacement 3510

Clean 3510

Inspect 3510

Assemble 3511

Install 3513

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) 3514

Remove 3514

Disassemble 3516

Standard Motor 3516

Enhanced Motor 3518

Electrical Connector Repair or Replacement 3519

Clean 3520

Inspect 3520

Assemble 3521

Standard Motor 3521

Enhanced Motor 3521

Install 3522

For Lift Truck Models ERP2 2-3 5VL (ERP045-070VL) (A976) and ERC16-20VA (ERC030-040VA) (A969) 3522

Remove 3522

Disassemble 3522

Electrical Connector Repair or Replacement 3528

Clean 3529

Inspect 3529

Assemble 3530

Install 3531

For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) and ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3531

Remove 3531

Disassemble 3531

Electrical Connector Repair or Replacement 3534

Clean 3534

Inspect 3535

Assemble 3535

Install 3536

Hydraulic Motor Repair For 4 0-5 5T Lift Trucks 3536

Remove 3536

Disassemble 3536

Electrical Connector Repair or Replacement 3538

Clean 3538

Inspect 3539

Assemble 3539

Install 3540

Torque Specifications 3541

Traction Motor for Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955) 3541

Traction Motor for Lift Truck and ERC22-35VG (ERC045-070VG) (A968), ERC16-20VA (ERC030-040VA) (A969),ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3541

Traction Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 3541

Hydraulic Motor for Lift Trucks and ERP15-20VT (ERP030-040VT) (G807)ERP16-20VF (ERP30-40VF) (A955) 3541

Hydraulic Motor for Lift Truck ERC22-35VG (ERC045-070VG) (A968) 3541

Hydraulic Motor for Lift Truck ERP22-35VG (ERP045-070VG) (A976) 3541

Hydraulic Motor for Lift Truck ERC16-20VA (ERC030-040VA) (A969) 3541

Hydraulic Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 3541

Hydraulic Motor for Lift Truck and ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985)ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3542

524327049-0620YRM1385-(06-2015)-UK-EN 3545

General 3549

Discharging the Capacitors for Lift Truck Models ESC030-040AC (B883), ESC030-040AD (C883) 3556

Discharging the Capacitors (All Other Models) 3557

Traction Motor Repair 3557

For Lift Truck Models ERP15-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), and ESC030-040AC (B883) 3558

Remove 3558

Disassemble 3559

Electrical Connector Repair or Replacement 3562

Clean 3562

Inspect 3562

Assemble 3563

Install 3566

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) and ERC16-20VA (ERC030-040VA) (A969) 3568

Remove 3568

Disassemble 3568

Electrical Connector Repair or Replacement 3572

Clean 3572

Inspect 3572

Assemble 3573

Install 3573

For Lift Truck ERP2 2-3 5VL (ERP045-070VL) (A976) 3573

Remove 3573

Disassemble 3573

Clean 3575

Inspect 3575

Assemble 3576

Install 3576

For Lift Truck ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3576

Remove 3576

Disassemble 3577

Electrical Connector Repair or Replacement 3578

Clean 3578

Inspect 3579

Assemble 3579

Install 3580

3580

Traction Motor Repair For Lift Truck ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985) 3580

Remove 3580

Clean 3582

Install 3582

Hydraulic Motor Repair 3582

For Lift Trucks ERP15-20VT (ERP030-040VT) (G807), ERP16-20VF (ERP30-40VF) (A955), and ESC030-040AC (B883), ESC030-040AD (C883) 3582

Remove 3582

Disassemble 3584

Electrical Connector Repair or Replacement 3586

Clean 3586

Inspect 3586

Assemble 3587

Install 3589

For Lift Truck ERC22-35VG (ERC045-070VG) (A968) 3591

Remove 3591

Disassemble 3592

Standard Motor 3592

Enhanced Motor 3593

Electrical Connector Repair or Replacement 3595

Clean 3596

Inspect 3597

Assemble 3597

Standard Motor 3597

Enhanced Motor 3598

Install 3599

For Lift Truck Models ERP2 2-3 5VL (ERP045-070VL) (A976) and ERC16-20VA (ERC030-040VA) (A969) 3600

Remove 3600

Disassemble 3600

Electrical Connector Repair or Replacement 3606

Clean 3607

Inspect 3607

Assemble 3608

Install 3609

3609

Hydraulic Motor Repair For 4 0-5 5T Lift Trucks 3609

Remove 3609

Disassemble 3609

Electrical Connector Repair or Replacement 3612

Clean 3613

Inspect 3613

Assemble 3614

Install 3614

Torque Specifications 3615

Traction Motor for Lift Trucks ERP15-20VT (ERP030-040VT) (G807) and ERP16-20VF (ERP30-40VF) (A955) 3615

Traction Motor for Lift Truck ERC22-35VG (ERC045-070VG) (A968), ERC16-20VA (ERC030-040VA) (A969), and ERC40-55VH, ERC50VHS (ERC80-120VH, ERC100VHS) (A938) 3615

Traction Motor for Lift Truck ESC030-040AC (B883), ESC030-040AD (C883) 3615

Hydraulic Motor for Lift Trucks ERP15-20VT (ERP030-040VT) (G807) and ERP16-20VF (ERP30-40VF) (A955) 3615