$41.95

Yale G876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual PDF

Yale Forklift G876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yale Forklift G876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

Language : English

Pages : 1114

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yale Forklift G876 (GDP190DC, GDP210DC, GDP230DC, GDP230DCS, GDP250DC, GDP280DC) Service Manual – PDF DOWNLOAD

524150797 8000YRM0231 (02 2023) US EN 1

General 7

Threaded Fasteners 7

Nomenclature, Threads 7

Strength Identification 8

Cotter (Split) Pins 9

Fastener Torque Tables 14

Conversion Table 16

524150797 8000YRM0231 (03 2020) US EN 23

General 27

Threaded Fasteners 27

Nomenclature, Threads 27

Strength Identification 28

Cotter (Split) Pins 29

Fastener Torque Tables 34

Conversion Table 36

524211827 0600YRM1101 (11 2018) US EN 43

Series Code / Model Designation Reference Table 47

General 47

Fault Codes 48

Normal Mode 48

Fault Log Mode 49

Access 49

Exit 49

Clear 49

Electronic Throttle Calibration 49

Electronic Throttle Calibration Procedure 50

Stationary Regeneration Procedure 50

550033398 0100YRM1459 (12 2018) US EN 79

Series Code / Model Designation Reference Table 83

Description and Operation 83

Heater System 83

General 83

Air Conditioning 84

General 84

Dryer 85

Compressor Lubrication 86

Control Systems, Sensors, and Switches 86

Climate Control 87

Description 87

Service Menu 87

Set Up 88

View 1 and View 2 88

Error List 89

Statistics 89

Exit 89

Temperature Sensors 89

Troubleshooting 89

Water Valve 90

Troubleshooting 90

Remove and Replace 92

Standard Heater Assembly 93

Access 93

Remove 93

Install 94

Standard Heater Parts 95

Heater Core 95

Remove 95

Install 96

Blower 96

Remove 96

Install 97

Water Valve 98

Remove 98

Install 98

Push/Pull Cable 99

Water Valve Cable 99

Remove 99

Install 99

Heater/Air Conditioner Assembly 100

Remove 100

Install 101

Heater/Air Conditioner Parts 101

Vent Door 101

Remove 101

Install 102

Heater Core 102

Remove 102

Install 103

Evaporator Core 104

Remove 104

Install 105

Blower 106

Remove 106

Install 106

Thermostat 107

Remove 107

Install 108

Water Valve 108

Remove 108

Install 109

Air Conditioning Technical Detail 110

550033400 0100YRM1390 (12 2018) US EN 113

Series Code / Model Designation Reference Table 121

General 121

Description of Operation 123

Cab Structure 123

Cab Tilt System 123

Cab Tip-Up System 125

Tilting the Cab 126

Raising 126

Lowering 127

Remove and Install 128

Cab Door Assembly 128

Cab Door 128

Remove 128

Install 128

Door Hinge 129

Remove 129

Install 129

Door Latch 130

Remove 130

Install 130

Door Handle 130

Remove 130

Install 130

Door Release 131

Remove 131

Install 131

Door Push Button 131

Remove 131

Install 132

Cab Tilt System 132

Electric Tilt Pump 132

Remove 132

Install 132

Hand Tilt Pump 132

Remove 132

Install 133

Cab Tilt Cylinder 134

Remove 134

Disassemble 134

Clean 136

Inspect 136

Assemble 136

Install 137

Latch 137

Remove 137

Install 138

Brake and Inching Pedal 139

Remove 139

Install 139

Accelerator Pedal and Sensor 140

Remove 140

Install 140

Adjust Sensor 140

Seat Assembly 140

Seat 140

Remove 140

Install 141

Seat Cushion 141

Remove 141

Install 142

Back Cushion 142

Remove 142

Install 142

Seat Suspension Replacement 142

Boot Replacement 142

Power Assist Armrest 166

Release Cable 166

Remove 166

Install 166

Gas Spring 166

Remove 166

Install 167

Joystick 167

Remove 167

Install 167

Electrical Levers 167

Remove 167

Install 168

Armrest Rocker Switches 168

Remove 168

Install 168

Armrest Top Cover 168

Remove 168

Install 168

Instrument Panel 169

Key Switch 169

Remove 169

Install 169

12V Power Socket 169

Remove 169

Install 169

Electric-Operated Heat Control and Air Recirculation Control (Airco Only) 170

Remove 170

Install 170

Cable-Operated Heater Control (Heater Only) 171

Remove 171

Install 171

Air Conditioning Switch Replacement 171

Instrument Panel Rocker Switches Replacement 171

Parking Brake Switch 172

Remove 172

Install 172

Indicator Display Replacement 172

Instrument Panel Top Console 172

Remove 172

Install 173

Steering Wheel and Column Assembly 173

Steering Wheel and Horn 173

Remove 173

Install 175

Steering Column Assembly 175

Remove 175

Install 176

Adjustment Handle 176

Remove 176

Install 176

Main Warning Lights 177

Remove 177

Install 177

Shift Lever 177

Remove 177

Install 177

Turn Signal Lever 177

Remove 177

Install 177

Window Wipers 178

Window Wiper Assembly Replacement 178

Remove 178

Install 178

Window Wiper Motor Replacement 178

Front Window Wiper Motor 178

Install 178

Rear Window Wiper Motor Assembly 179

Remove 179

Install 179

Top Window Wiper Motor Assembly 179

Remove 179

Install 179

Window Washer System 180

Window Washer Reservoir and Pumps 180

Remove 180

Install 180

Window Washer Hoses 181

Hoses for Top and Rear Window 181

Install 182

Window Washer Spray Nozzles 182

Front Window 182

Remove 182

Install 182

Rear Window 183

Remove 183

Install 183

Top Window 183

Remove 183

Install 183

Window Replacement 183

Front Window 185

Remove 185

Install 185

Rear Window 185

Remove 185

Install 185

Top Window 186

Remove 186

Install 186

Door, Upper/Lower Window 187

Remove 187

Install 187

Sliding Window and Sliding Tracks 187

Remove 187

Install 189

Weather Strip Replacement 189

Window Stopper Replacement 189

Window Seal Replacement 190

Sliding Window Frame 190

Remove 190

Install 190

Floor Mat 190

Front Floor Mat 190

Remove 190

Install 191

Rear Floor Mat 191

Remove 191

Install 192

Radio Console 192

Remove 192

Install 192

Air Duct Replacement 193

Remove Front 193

Remove Rear 193

Install 194

Accessories 194

Mirror Replacement 194

Sunshade Replacement 194

Top 194

Rear 195

Map Light Replacement 195

Interior Fan Replacement 195

Training Seat 195

Field Installation 195

Remove 195

Label Replacement 196

Checks and Adjustments 196

Check Oil Level for Cab Tilt System 196

Door Striker Pin Adjustment 197

Brake Pedal Adjustment 197

Dry Brake 197

Wet Brake 198

Inching Pedal Adjustment 198

Inching Pedal Sensor Adjustment 198

Sensor Adjustment Using Dana Dashboard Software 198

Sensor Adjustment using the APC200 Display 199

Sensor Adjustment for Trucks with ZF Transmission 200

Inching Pedal Sensor Calibration 200

Sensor Calibration using Dana Dashboard Software 200

Sensor Calibration using APC200 Display 200

Sensor Calibration for Trucks with ZF Transmission 201

550035502 1300YRM1455 (11 2018) US EN 205

Series Code / Model Designation Reference Table 209

General 209

Description 209

General 209

Clutch 214

Operation 214

Hydraulic Operation 214

Clutch Valve 215

Cooling and Lubrication 216

Control System 217

Transmission Control Unit (TCU) 218

Operating Modes 218

Normal Mode 218

Substitute Clutch Control 218

Limp-Home Mode 218

Transmission Shut Down Mode 218

TCU Shut Down Mode 218

Transmission Exceed Codes 218

Self-Test 219

Fault Codes 219

Description 219

Fault Log Mode 219

Access 219

Exit 220

Clear 220

Fault Log Memory 220

Fault Rectification 220

Hydraulic Control Valve 221

Hydraulic Control Valve Repair 222

Solenoid Replacement 222

Pressure Check 222

Pressure Specifications 223

Speed and Temperature Sensors 223

Speed Sensors 224

Test 225

Temperature Sensors 225

Shift Lever 225

PedalFoot Directional Control 225

ZF Transmission Test and Calibration 226

Transmission Test and Calibration 226

Precautions 226

Stall Test 226

Description 226

Stall Test Procedure 226

Inch Pedal Calibration 227

Description 227

Calibration 227

Brake and Inch Pedal Adjustment 227

Inch Sensor Adjustment 227

Inch Pedal Calibration 228

Preparation 228

Calibration Procedure Using the Calibration Switch 228

Calibration Procedure Using the Testman software 228

Inch Pedal Calibration Fault Codes 228

Clutch Calibration 229

Description 229

Clutch Calibration Procedure 230

Manual Clutch Calibration Procedure 230

Testman Clutch Calibration Procedure 231

Testman 231

Description 231

Connection 232

Truck Configuration 232

Configuration 232

Limitations 232

Capacities and Specifications 233

Electrical Specifications 233

Transmission Control Unit Diagram 233

ZF Transmission Fault Codes 235

Transmission Exceed Codes 235

Testman Fault Codes 236

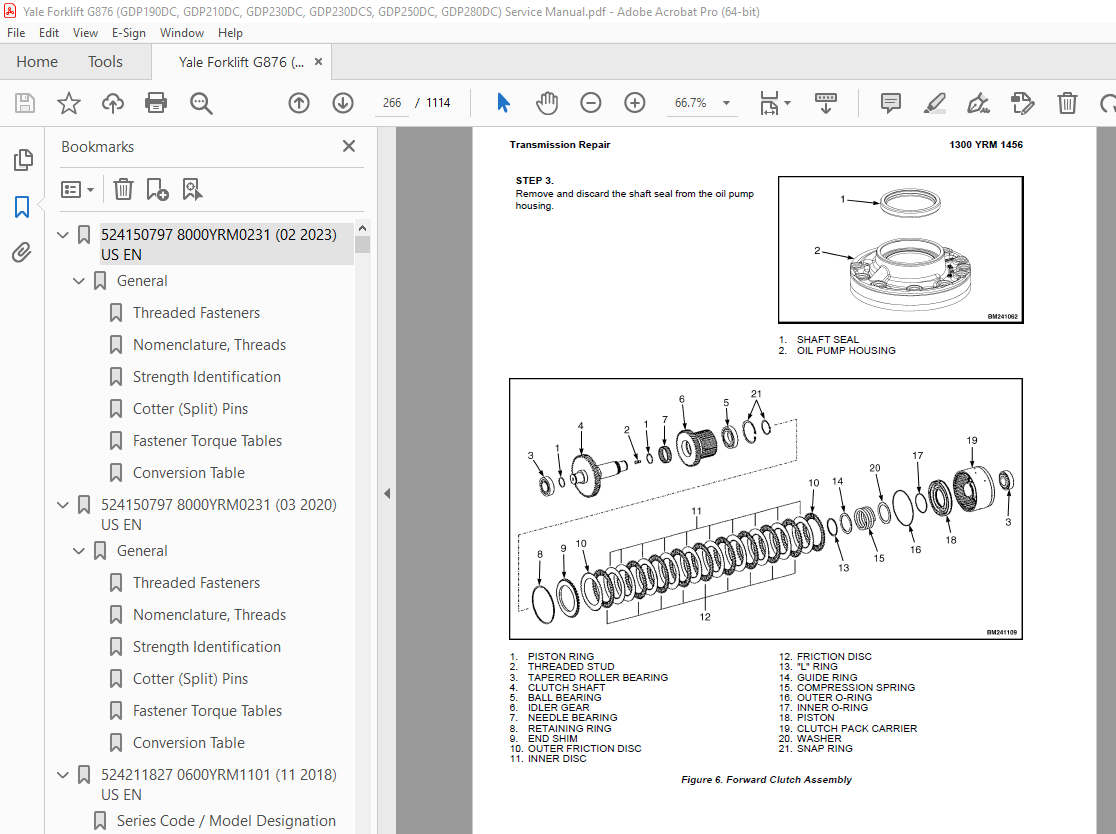

550035503 1300YRM1456 (12 2015) US EN 247

Series Code / Model Designation Reference Table 251

Special Tools List 252

Transmission Repair 253

Remove 253

Disassemble 257

Clean and Inspect 296

Housings 297

Oil Seals and Gaskets 297

Bearings 297

Gears and Shafts 297

Assemble 298

Transmission Oil Filter Assembly Replacement 345

Clean 346

Inspect 346

Install 347

Control Valve Replacement 352

Remove 352

Install 353

Control Valve Repair 354

Disassemble 354

Clean 358

Inspect 358

Assemble 359

550088524 4000YRM1647 (07 2016) US EN 367

Series Code / Model Designation Reference Table 373

General 373

Description And Operation 373

Mast System 373

Tilting 373

Lifting 374

Operation 374

Pilot Operated Check Valves 375

Gland Lubrication 376

Emergency Lowering Valve 376

Operation 376

Lift Chains 377

Elongation Through Wear 377

Speed of Wear 377

Plate Height Wear 378

Lubrication 378

Restoring The Oil Film 378

Maintenance 378

Maintaining The Presence of Oil 379

Corrosion Protection 379

Requirements for Chain Lubricant 379

Load Rollers 380

Bearing Blocks 380

Carriage 381

Standard Carriage with Manual Fork Positioning 381

Standard Carriage with Hydraulic Fork Positioning 381

Dual Function Side Shift and Fork Positioning (DFSSFP) Carriage 382

Integral Side Shift 382

Carriage Valve 383

Alternating Pressure and Tank (P & T) 383

Fixed Pressure and Tank (P & T) 383

Flow Divider for Simultaneous Fork Positioning 383

Valve for Dual Function with Side Shift and Fork Positioning (DFSSFP) 385

Fixed Pressure and Tank System (Fixed P & T) 387

Forks 389

Safety Procedures When Working Near Mast 390

Before Starting Repairs to the Hydraulic System, Always: 391

Remove and Replace 391

Forks 391

Remove 391

Install 392

Fork Guide And Fork Pin 393

Remove 393

Install 393

Carriage 394

394

Remove 394

Install 395

Carriage Bearing Blocks 396

Remove 396

Install 397

397

Carriage Load Rollers 397

Replace 397

399

Side Shift Cylinder 399

Remove 399

Disassemble 399

Clean And Inspect 400

Assemble 400

Install 401

Fork Positioner Cylinder 401

Remove 401

Disassemble 402

Clean and Inspect 402

Assemble 403

Install 403

Carriage Valves 403

Remove 403

Install 404

404

Valve for Fixed P & T Systems 404

Remove and Disassemble 404

Clean and Inspect 406

Assemble and Install 406

Flow Divider for Simultaneous Fork Positioning Valve 407

Restrictor Valve and Relief Valve Replacement 407

Dual Function Valve for Side Shifting and Fork Positioning 407

Solenoid Valve Replacement 407

Relief Valve Replacement 408

Remove 408

Install 408

Mast 408

Lift Chains and Top Chain Anchor 408

Remove 408

Install 408

Chain Anchor On Carriage 409

Remove 409

Install 409

Chain Sheave 410

Remove 410

Install 410

Header Hoses 411

Remove 411

Install 413

Electric Mast Cable 413

Remove 413

Install 413

Hose Sheave 414

Remove and Disassemble 414

Assemble and Install 414

Mast Assembly 415

Remove 415

Disassemble 417

Assemble 418

Install 419

Inner Mast Load Rollers 421

Replace 421

Mast Bearing Blocks 422

Remove 422

Install 422

Lift Cylinders 423

Remove 423

Disassemble 426

Clean and Inspect 426

Assemble 426

Install 427

Tilt Cylinders 428

Remove 428

Disassemble 429

Clean and Inspect 429

Assemble 429

Install 430

Checks and Adjustments 431

General Checks 431

Mast Condition Check 431

Mast Operation Check 432

Counterbalance Valve Check (for E876 and E877 Only) 432

Fork Inspection and Adjustment 432

Lift Chain Inspection 433

Lift Chain Lubricant Requirements 434

Lift Chain Lubrication Procedure 434

Leak Checks 434

Mast Vertical Creep 434

Mast Tilt Drift 435

Adjustments 435

Lift Cylinder Shimming 435

Lift Chain and Fork Height Adjustment 437

Header Hose Tension Adjustment 439

Electric Mast Cable Tension Adjustment 439

Counterbalance Valve Adjustment 439

Tilt Cylinder Backward Tilt Angle Adjustment 440

Mast Support Pad Adjustment 440

Troubleshooting 440

Introduction 441

No Hydraulic Movement With Engine Running 441

Initial Basic Check 441

442

Electrical Supply 442

Hydraulic Supply 442

Fault Code 442

No Lowering Possible with Engine OFF 443

Incorrect Movement 443

Irregular (shaking) Movement

or

Slight Carriage Movement When Starting Engine

443

Unequal Movement of Left And Right Tilt Cylinder 443

Insufficient Lifting Speed 443

Insufficient Lifting Capacity 444

Incorrect Lowering Speed 444

Lift Cylinder Creep 444

Tilt Cylinder Creep 444

550123389 0100YRM1900 (12 2015) US EN 447

Series Code / Model Designation Reference Table 451

General 451

Description 451

Remove and Install 452

Air Filter Assembly (Tier 3/Stage IIIA) 453

Remove 453

Install 453

Air Filter Assembly (Tier 4F/Stage IV) 454

Remove 454

Install 454

Exhaust System (Tier 3/Stage IIIA) 455

Remove 455

Install 455

Exhaust System (Tier 4F/Stage IV) 456

Exhaust Pipes High Mount 456

Remove 456

Install 456

Exhaust Pipes and Diffuser Low Mount 457

Remove 457

Install 457

Exhaust Seal Rings 457

Selective Catalytic Reducer (SCR) 458

Remove 458

Install 458

Decomposition Reactor Tube (DRT) 458

Remove 458

Install 459

Diesel Oxidation Catalyst (DOC) 459

Remove 459

Install 459

Hood Assembly 459

Remove 459

Install 461

Running Boards, Steps and Mud Flaps 461

Hydraulic Tank 462

Remove 462

Inspect 465

Clean 465

Steam Cleaning Method 465

Chemical Solution Cleaning Method 465

Repair 466

Small Leaks 466

Large Leaks 466

Inspection after Repair 466

Install 466

Fuel Tank 468

Remove 468

Clean and Repair 469

Install 469

Engine and Transmission (Tier 3/Stage IIIA) 470

Remove 470

Precautions 470

Remove Air Conditioning Compressor 471

Drain the Engine Cooling System 472

Drain Hydraulic Oil 472

Drain Transmission Oil 472

Disconnect Drive Shaft, Fan Clutch, Tubes, Pipes, Cables, Wires and Lines 473

Remove Engine and Transmission 475

Install 477

Install Engine and Transmission 477

Install Air Conditioning Compressor 477

Connect Drive Shaft, Fan, Tubes, Pipes, Cables, Wires and Lines 477

Refill the Systems 478

Starting the Engine 478

Engine and Transmission (Tier 4F/Stage IV) 479

Remove 479

Precautions 479

Remove Air Conditioning Compressor 479

Drain the Engine Cooling System 480

Drain Hydraulic Oil 481

Drain Transmission Oil 481

Disconnect Drive Shaft, Fan Clutch, Tubes, Pipes, Cables, Wires and Lines 481

Remove Engine and Transmission 483

Install 484

Install Engine and Transmission 484

Install Air Conditioning Compressor 484

Connect Drive Shaft, Fan, Tubes, Pipes, Cables, Wires and Lines 485

Refill the Systems 485

Starting the Engine 486

Operator’s Cab 486

Remove 486

Install 488

Cab Tilt System Oil Filling 489

Counterweight 490

Remove 491

Install 492

Label Replacement 492

550123390 0700YRM1929 (11 2018) US EN 495

Series Code / Model Designation Reference Table 499

General 499

Cooling System 499

Cooling System Description 499

Cooling Cores 499

Fan 500

Fan Clutch 500

Fan Clutch Engagement 500

Shroud 501

Engine Cooling System 502

Water Pump 502

Thermostat 502

Expansion Tank And Radiator Cap 503

Cab Heater 503

Coolant 504

DEF Heater 505

Charge Air Cooling System 505

Transmission Oil Cooling System 505

Hydraulic Oil Cooling System 506

Hydraulic Oil Cooling 506

Oil Filtration and Oil Cooling 507

Brake Cooling 508

Hydraulic Control System 508

Service and Repair 508

Cooling System Checks 508

Basic Checks 508

Coolant Quality Checks 509

Coolant Flow Checks 509

Thermostat 509

Water Pump 510

Cooling Core Efficiency 510

Cooling Core Flow Restrictions 511

Engine Leak Tests 511

External Leak Test 511

Check for Coolant Leak Into The Engine Oil Sump 512

Combustion Leak Test 513

Engine Cooling System Maintenance 513

Draining the Engine Cooling System 513

Filling the Engine Cooling System 514

Flushing the Engine Cooling System 514

Cleaning the Engine Cooling System 515

Remove and Replace 515

Fan 515

Remove 515

Install 515

Drive Belt 516

Remove 516

Install 516

Belt Tensioner 517

Inspect 517

Remove 517

Install 517

Water Pump 517

Inspect 517

Remove 517

Install 518

Thermostat 518

Remove 518

Inspect 518

Install 519

Cooling Core Assembly 519

Remove 519

Cooling Cores 523

Disassembly 523

Assembly 523

Install 523

550123391 0900YRM1930 (11 2018) US EN 529

General 533

Description and Operation 533

Remove and Replace 542

DEF Tank 542

Remove 542

Install 543

DEF Tank Fill Cap 543

DEF Tank Unit 543

Remove 543

Install 543

DEF Tank Suction Filter 544

Replace 544

DEF Pump Assembly 545

Remove 545

Install 545

DEF Pump Filter 545

Replace 545

DEF Dosing Valve 546

Remove 546

Checks and Adjustments 547

DEF Dosing Valve 547

DEF Pump 547

550123392 1400YRM1931 (09 2015) US EN 551

General 555

555

Identification Plate 556

Description and Operation 556

Drive Axle 556

Planetary Gear Assembly 556

Differential 558

Drive Shaft 558

Remove and Replace 558

Precautions 559

Putting the Lift Truck on Blocks 559

Drive Shaft 559

Remove 559

Disassemble 560

Clean and Inspect 561

Assemble 561

Install 561

Planetary Gear Assembly 561

Planetary Spider 563

Remove 563

Disassemble 564

Inspect 565

Assemble 565

Install 565

Planetary Sun Gear, Axle Shaft and Ring Gear Hub 566

Remove and Disassemble 566

Inspect 567

Assemble and Install 568

Wheel Hub 568

Remove and Disassemble 568

Inspect 569

Assemble and Install 570

Toric Ring Face Seal Assembly 570

Remove 570

Inspect 571

Install 571

Check for Correct Installation 572

Wet Disc Brake Assembly 574

Brake Disc Housing Assembly 575

Remove and Disassemble 575

Inspect 577

Assemble and Install 577

Brake Piston Assembly 578

Remove and Disassemble 578

Inspect 579

Assemble and Install 580

Brake Piston Housing and Wheel Spindle 580

Remove 580

Inspect 581

Install Spindle 582

Install Brake Piston Housing 582

Drive Axle 584

Remove 584

Install 585

Differential 586

Remove 588

Remove Axle Shafts 588

Remove the Differential Carrier from the Axle 588

Remove Differential and Ring Gear from the Carrier 589

Remove Drive Pinion and Bearing Cage from the Carrier 591

Disassemble 592

Disassemble Differential and Ring Gear 592

Disassemble Drive Pinion and Pinion Carrier 593

Clean and Inspect 595

Yoke 595

Drive Axle 595

Tapered Roller Bearings 595

Pinions and Gears 595

Axle Shafts 595

Main Differential Assembly 595

Assemble, Adjust and Install 596

Assemble Drive Pinion, Bearings and Bearing Cage 596

Install Spigot Bearing on the Drive Pinion 597

Install Drive Pinion in the Bearing Cage 597

Measure Pinion Bearing Preload, Press Method 598

Measure Pinion Bearing Preload, Flange Method 599

Adjust Pinion Bearing Preload 602

Install Drive Pinion, Bearing Cage and Shim Pack into the Carrier 604

Assemble Differential and Ring Gear 605

Assemble Differential and Ring Gear, Check Differential Gears Rotating Torque 606

Assemble Differential and Ring Gear, Install Differential and Ring Gear Assembly 607

Adjust Differential Bearing Preload 608

Check Ring Gear Runout 609

Check and Adjust Ring Gear Tooth Contact, Prepare 610

Check and Adjust Ring Gear Tooth Contact, Correct Tooth Contact 610

Check and Adjust Ring Gear Tooth Contact, Incorrect Tooth Contact 610

Check and Adjust Ring Gear Tooth Contact, Adjust Ring Gear Backlash 611

Check and Adjust Ring Gear Tooth Contact, Lock Adjusting Rings 612

Adjust the Thrust Screw 612

Install Differential Assembly in Axle Housing 612

Capacities and Specifications 614

Torque Specifications 614

Lubrication Specifications 617

550123393 1600YRM1932 (11 2018) US EN 621

General 625

Steering System Main Component Identification 625

Description and Operation 629

Steering System 629

Introduction 629

Description 629

Hydraulic Oil Flow Path 629

Priority Valve 629

Fundamentals 629

Description 629

Operation 629

Component Validation for Correct Operation 630

Steering Control Unit 630

Description 630

Steering Control Valve 630

Fundamentals 630

Operation 630

Component Validation for Correct Operation 631

Hand Pump 631

Fundamentals 631

Operation 631

Component Validation for Correct Operation 631

LS Relief Valve 631

Fundamental 631

Operation 631

Component Validation for Correct Operation 631

Shock Valve 631

Fundamental 631

Operation 631

Component Validation for Correct Operation 631

Steering Axle 631

Hydraulic Troubleshooting Flowcharts 632

Hydraulic Pressure Checks Preparation 632

Steering Relief Pressure Check 633

Pressure Check, Port MLS1 and MLS2 on the Main Control Valve 633

Steering Wheel Lock to Lock Check 634

Flowchart 635

Hydraulic Pressure Checks for Troubleshooting Flowcharts 635

Hydraulic Pressure Checks Preparation 636

Condition Check, Shuttle Valve L and M in the Main Control Valve 636

Condition Check, Logic Element N in the Main Control Valve 637

Condition Check, Priority Valve on the Main Control Valve 637

Remove and Replace 637

Steering Control Unit 637

Remove 637

Install 639

Wheels 640

Remove Wheels From Lift Truck 640

Install Wheels on Lift Truck 640

Steer Axle (G876/G877/A674) 641

Remove 641

Install 642

Tie Rod (G876/G877/A674) 644

Remove 644

Clean and Inspect 644

Install 644

Steering Cylinder (G876/G877/A674) 644

Remove 644

Clean and Inspect 646

Assemble and Install 648

Hubs (G876/G877/A674) 648

Remove and Disassemble 648

Clean and Inspect 648

Assemble and Install 648

Spindle (G876/G877/A674) 649

Remove 649

Clean 650

Assemble and Install 650

Steering Axle (A674) 650

Remove 650

Install 651

Tie Rod (A674) 652

Remove 652

Clean and Inspect 653

Install 653

Steering Cylinder (A674) 653

Remove 653

Clean and Inspect 656

Assemble and Install 656

Hubs (A674) 657

Remove and Disassemble 657

Clean and Inspect 658

Assemble and Install 658

Spindle 659

Remove 659

Clean and Inspect 660

Assemble and Install 660

Checks and Adjustments 660

Maximum Steering Angle Adjustment (G876/G877/A674) 660

Maximum Steering Angle Adjustment (A674) 661

Torque Specifications 661

Steering Control Unit 661

Steering Axle 661

Wheel Nuts 661

Steering Cylinder 661

550123394 1800YRM1933 (11 2018) US EN 665

General 671

Brake System Main Component Identification 671

Description 674

Brake System 675

Service Brakes 675

Park Brake 675

Description 675

Hydraulic Oil Flow Path 675

Brake Accumulator Charging System 675

Service Brake System 675

Park Brake System 675

Priority Valve 676

Fundamentals 676

Description 676

Operation 676

Component Validation for Correct Operation 676

Brake Control Manifold 676

Description 676

Orifice (F) 677

Fundamentals 677

Description 677

Operation 677

Component Validation for Correct Operation 678

Unloading Valve 678

Fundamentals 678

Operation 678

Component Validation for Correct Operation 678

Screen 678

Description 678

Component Validation for Correct Operation 678

Check Valve 678

Description 678

Component Validation for Correct Operation 678

Pressure Reducer Valve 678

Fundamentals 678

Operation 678

Component Validation for Correct Operation 678

Park Brake Selector Valve 678

Fundamentals 678

Operation 678

Component Validation for Correct Operation 678

Brake Accumulator 678

Fundamentals 678

Operation 679

Component Validation for Correct Operation 679

Brake Treadle Valve 679

Fundamentals 679

Description 679

Operation 679

Brake Treadle Valve Repair 679

Remove 679

Install 680

Accumulator 680

Remove 680

Disassemble 681

Clean 684

Inspect 684

Repair 684

Assemble 684

Install 685

Pre-Charge Filling 685

Parking Brake 686

Parking Brake Caliper 686

Remove 686

Disassemble 688

Clean and Inspect 689

Assemble 689

Install 690

Parking Brake Caliper Pads 690

Remove 690

Install 690

Parking Brake Bleed 690

Parking Brake Emergency Release 691

Brake Flow Distribution Manifold 691

Remove 691

Pressure Relief Valve 693

Disassemble 693

Clean and Inspect 694

Assemble 694

Install 694

Brake Control Manifold 694

Remove 695

Orifices F and G 696

Disassemble 696

Assemble 696

Orifice H 696

Disassemble 696

Assemble 696

Unloading Valve (B) 696

Disassemble 696

Assemble 697

Screen 697

Disassemble 697

Assemble 697

Check Valve (E) 697

Disassemble 697

Assemble 697

Pressure Reducer Valve (C) 697

Disassemble 697

Assemble 698

Park Brake Selector Valve (A) 698

Disassemble 698

Assemble 698

Install 699

Gear Pump 699

Remove 699

Disassemble 699

Clean 700

Inspect 701

Assemble 701

Install 702

Hydraulic Troubleshooting Flowcharts 703

Mechanical Troubleshooting 706

Checks and Adjustments 707

Hydraulic Pressure Checks Preparation 707

Park Brake Selector Valve Check 708

Park Brake Selector Valve Coil Check 708

Accumulator Pre-Charge Check 708

Parking Brake Adjustment 709

Condition Check, Shuttle Valve L in the Main Control Valve 710

Condition Check, Shuttle Valve N in the Main Control Valve 710

Condition Check, Priority Valve on the Main Control Valve 711

Pressure Check, Port MLS1 711

Torque Specifications 711

Hydraulic Hose Torque Specifications 711

550123395 1900YRM1934 (04 2020) US EN 715

Fundamentals 723

Basic Principles of Flow Control Systems 723

Orifice (Fixed/Variable) 723

Basic Principle 723

Pressure Compensated Flow Control Valve 724

Basic Principle 724

Pressure Compensated Flow Control Valve Functional Description 724

Priority Valve 725

Basic Principle 725

Priority Valve Functional Description 725

Load Sense (LS) 726

Basic Principle 726

Load Sense Functional Description 726

Example 1 727

Example 2 727

Basic Principles of Pressure Control Systems 727

Direct Acting Relief Valves 728

Basic Principle 728

Direct Acting Relief Valve Functional Description 728

Two-Stage Relief Valve (Pilot-Operated Relief Valve) 728

Basic Principle 728

Two-Stage Relief Valve (Pilot-Operated Relief Valve) Functional Description 729

Pilot-Operated Selector Valves 730

Fundamentals 730

Function Description 730

Pump Pressure Free Flow Side 730

Function Pressure Blocked Flow Side 730

Unloading Valve (Accumulator Charging Valve) 731

Basic Principle 731

Unloading Valve (Accumulator Charging Valve) Functional Description 731

Counterbalance Valve 732

Basic Principle 732

Counterbalance Valve Functional Description 732

Pressure Reducer Valve 733

Basic Principle 733

Pressure Reducer Valve Functional Description 733

Description and Operation 734

Component Location and Identification 734

Main Control Valve 737

Introduction 737

Flow Path 737

Main Manifold 737

Introduction 737

Priority Valve (A) 738

Fundamentals 738

Description 738

Operation 738

Component Functionality Test 738

Check Valve (I) 738

Function Description 738

Function Operation 738

Component Functionality Test 738

Pilot Supply Circuit 738

Function Description 738

Pilot Supply Valve (F) 738

Fundamentals 738

Function Description 738

Function Operation 739

Component Functionality Test 739

Lift Pressure Selector Valve (B) 739

Function Description 739

Function Operation 739

Component Functionality Test 739

Check Valve (K) 739

Function Description 739

Component Functionality Test 739

Check Valve (Q) 739

Function Description 739

Component Functionality Test 739

Screen (O) 739

Function Description 739

Component Functionality Test 739

Relief Valve 739

Function Description 739

Load Sense Relief Valve (H) 740

Fundamentals 740

Functional Operation 740

Component Functionality Test 740

Pressure Controller on Pump 740

Fundamentals 740

Functional Operation 740

Component Functionality Test 740

Full Flow Relief Valve (C) and (G) 740

Fundamentals 740

Functional Operation 740

Component Functionality Test 740

Shuttle Valve (L) and (M) 741

Function Description 741

Component Functionality Test 741

Logic Valve (N) 741

Function Description 741

Function Operation 741

Load Sense Selector Valve (D) 741

Function Description 741

Component Functionality Test 741

Directional Control Valve Section 741

Functional Operation (System Level) 741

Directional Control Valve 742

Fundamentals 742

Description 742

Functional Operation 742

Electrical Actuation Module (Solenoid End Cap) 743

Functional Operation 743

Component Functionality Test 743

Lift Function 743

Function Description 743

Pilot-Operated Check Valve 744

Fundamentals 744

Function Description 744

Function Operation 744

Emergency Lowering Valve (LH Lift Section ONLY) 744

Function Description 744

Lowering Control Valve 744

Fundamentals 744

Function Description 744

Tilt Function 744

Function Description 744

Impact Relief Valve 745

Fundamentals 745

Function Description 745

Counterbalance Valve 745

Fundamentals 745

Function Description 745

Auxiliary Function 745

Function Description 745

Variable Displacement Pump 746

Function Description 746

Basic Functional Operation 746

Pressure Control Valve 747

Fundamentals 747

Operation 747

Load Sense Pressure Regulator 747

Fundamentals 747

Functional Operation 747

Repair 747

Main Control Valve 747

Remove 747

Clean 751

Inspect 751

Assemble 751

Install 752

Priority Valve (A) 753

Remove 753

Clean 753

Inspect 754

Component Functionality Test 754

Install 754

Check Valve (K) 754

Remove 754

Clean 754

Inspect 754

Component Functionality Test 754

Install 754

Check Valve (I) 754

Remove 754

Clean 754

Inspect 755

Component Functionality Test 755

Install 755

Check Valve (Q) 755

Remove 755

Clean 755

Inspect 755

Component Functionality Test 755

Install 755

Screen Cartridge (O) 755

Disassemble 755

Component Functionality Test 755

Assemble 755

Shuttle Valves (L) and (M) 756

Remove 756

Clean 756

Inspect 756

Component Functionality Test 756

Install 756

Logic Valve (N) 757

Remove 757

Clean 757

Inspect 757

Component Functionality Test 757

Install 757

Full Flow Relief Valve (c) (Relief Spool) 757

Remove 757

Clean 757

Inspect 758

Assemble 758

Install 758

Pilot Supply Valve (F) 758

Remove 758

Clean 758

Inspect 758

Assemble 758

Component Functionality Test 758

Install 758

Load Sense (LS) Relief Valve (H) and Full Flow Relief Valve (G) 758

Remove 758

Clean 758

Inspect 759

Component Functionality Test 759

Install 759

Load Sense Relief Valve (H) Adjustment 759

Full Flow Relief Valve (G) Adjustment 759

Load Sense Selector Valve (D) 759

Remove 759

Clean 759

Inspect 760

Assemble 760

Install 760

Lift Pressure Selector Valve (B) 760

Remove 760

Clean 760

Inspect 760

Assemble 760

Install 760

Variable Displacement Pump (Primary and Secondary) 761

Remove 761

Clean 762

Inspect 762

Assemble 762

Install 762

Electrical Actuation Module 763

Remove 763

Clean 763

Inspect 763

Assemble 764

Install 764

Emergency Lowering Valve (Left Slice Only) 765

Remove 765

Clean 765

Inspect 765

Install 765

Load Sense and Pressure Controller Valve on Pump 765

Remove 765

Clean 766

Inspect 766

Assemble 766

Install 766

Adjustment of Pressure Controller on Pump 766

Adjustment of Load Sense Controller on the Secondary Variable Pump 767

Adjustment of Load Sense Controller on the Primary Variable Pump 768

Directional Control Valve 769

Remove 769

Clean 769

Inspect 769

Assemble 769

Install 769

Manual End Cap 769

Remove 770

Clean 770

Inspect 771

Assemble 771

Install 771

Troubleshooting 771

Lift, Tilt, and/or Aux function does not move when applied Steering is operating normal 771

The truck is not

capable to lift

rated load at expected

max lift

speed 772

Tilt function

shakes 772

It is not

possible to

lower the

mast with

ignition key

turned to

ON 772

Steer and

brake accumulator

charge

function

does not operate 772

The truck is

hydraulically

loaded

during engine

start

Accumulator

charge

and steering

is possible

during

XMSN calibration 773

Torque Specifications 773

Torque Specifications 773

550123396 1900YRM1935 (01 2016) US EN 775

General 779

Safety Precautions and Tips 779

List of Terms and Abbreviations 780

Installing the Hydraulic User Interface Program 780

Starting the Hydraulic User Interface Program 780

780

Truck Selection Window 781

Start Screen/Language Selection 781

Warning Screen 784

Basic Screen Explanation 785

Truck Configuration 785

786

Pump Selection 786

Control Selection 787

Front-End Selection 787

Responsiveness Settings 787

Interrupt Selection 787

Units selection 788

All Parameter Screen 788

Installed Features 788

789

Software Enabled Options 790

Dynamic Control 790

High Temperature Protection 790

Loaded Speed Reduction 791

Standard Installed Features 792

Anti-stall 792

Cold Temperature Protection 792

Drive/Hydraulic Priority 793

Automatic Throttle Up 793

HIP/ECO Operating Mode 793

Hibernate Idle 794

Dynamic Pump Control 796

Calibration Screen 797

Flow Settings 799

Valve Settings 800

About Valve Actuation 801

Diagnostics 802

Hydraulic Diagnostics 802

Interrupt Indicators 802

Main Valve Solenoid Power Supply 803

Operator Presence 803

Lift Interrupt 803

Lower Interrupt 803

Controller Information 804

Active Errors 805

Error History 806

Fault Code Table 807

HCU Pinning 814

File Uploads/Downloads 818

Connecting to the Hydraulic Control Unit 818

Setup a Connection 818

Check the Current Software Version 827

Download a P1T (Parameter-file) 830

Download a ROP File 831

Tips and Tricks 833

Controller Identification 833

550123397 2200YRM1936 (11 2018) US EN 837

General 841

Electrical Schematic and System Description 841

Electrical Schematic 841

Schematic Location Number 844

Electrical Components 844

Electrical Wires 844

Wire Identification Number 844

Electrical Wire Colors 845

Wire Harnesses 846

Harness Interconnection 848

Electrical Connectors 848

Connector Types 848

Connector Identification 849

Connector Pin Numbers 849

Connector Description 849

Fuses 849

Relays 853

Flyback Diodes 855

CAN (Controller Area Network) 855

Troubleshooting 856

Instrument Panel 856

Instrument Panel Connectors 859

LCD Display 860

Hourmeter Mode 860

Fault Code Mode 860

Transmission Calibration 861

Fault Code Log Mode 861

Access 861

Clear 861

Exit 862

General Fault Finding 862

Preparation 862

Define the Problem Area 862

Identify Possible Causes of Malfunction 862

Determine the Most Probable Cause 862

Fuse Check 862

Wiring Check 862

Component Check 862

Repair and Test 862

Wire Harness Identification and Connector Location 863

Frame Harness Connectors 873

Mast ECH Harness Connectors 875

Top Cab Harness Connectors 876

Side Console Harness Connectors 878

Cab Underfloor Harness Connectors 881

Armrest Harness Connectors 883

ECM Harness Connectors (Tier 3/Stage IIIA) 884

EAS/ECM Harness Connectors (Tier 4F/Stage IV) 885

DEF Tank Harness Connectors 887

Powertrain Harness Connectors 887

Hoodspine Harness Tier 3/Stage IIIA Connectors 888

Hoodspine Harness Tier 4F/Stage IV Connectors 889

550123398 8000YRM1937 (10 2016) US EN 893

Counterweight Weights 897

Lift Truck Weights 898

Capacities 899

Electrical System 900

Engine Specifications 900

Mast Speeds 902

Tire Sizes 903

Hydraulic System 903

Torque Specifications, General 904

Transmission ZF 904

Driveline and Axle 904

Counterweight 904

Differential 904

Brakes – Wet 904

Steering 904

Wheel Nuts 904

Hydraulic System 905

Mast 905

Carriage 905

Tilt Cylinders 905

Wiper Arms, Front 906

Torque Specifications, Cummins Diesel 906

Lubrication System 906

550123399 8000YRM1938 (12 2016) US EN 909

Electrical Schematic T3/T4 Final 913

Hydraulic Schematic 942

550123400 8000YRM1939 (01 2021) US EN 955

General 961

Serial Number Data 961

Truck Handling Procedures 962

Moving and Towing a Lift Truck 962

Precautions 962

Moving the Truck 962

Putting a Lift Truck on Blocks 963

Raising the Drive Tires 963

Raising the Steering Tires 963

Cleaning a Lift Truck 964

Safety Procedures Before Starting Maintenance 965

Making Checks From the Driver Seat with Engine Running 965

Fire Hazard 965

Hydraulic Service Switch 966

Transmission Calibration Switch 966

Wait 100 Seconds Before Disconnecting Battery 966

Periodic Maintenance Schedule 966

Daily Inspection 967

Daily Condition Checks 967

Daily Fluid Level Checks 969

Daily Checks from the Driver Seat with Engine Running 969

Initial Inspection 970

First Inspection after First 100 Hours of Operation 970

Periodic Maintenance 971

Inspect and Adjust 971

Lubricate 974

Change 975

Periodic Maintenance Procedures 976

Air Conditioning System 976

Attachment 976

Brake Cooling Filter 976

Brake System Accumulator 977

Cab Air Filter 977

Cab Door Hinges 978

Control Levers, Switches, and Pedals 978

Cooling System 978

Coolant Hoses 978

Coolant Level 978

Coolant Quality 979

Cooling Fan 979

Cooling Fan Belt 979

Cooling Fan Belt Tensioner and Pulleys 979

Bearing Condition 979

Pulley Alignment 980

Tensioner Condition 980

Crankcase Breather Element (Tier 4F/Stage IV Only) 981

Diesel Exhaust Fluid (DEF) System 981

DEF Pump Filter 981

DEF Tank Fill Cap 982

DEF Tank Suction Filter 982

Drive Axle and Differential 983

Check Oil level 983

Change Oil 984

Drive Shaft 984

Engine Air Filter 984

Engine Air Intake Piping and Charge Air Piping 985

Engine and Transmission Mounts 985

Engine Compartment 986

Engine Oil 986

Engine Oil Level 986

Engine Oil and Engine Oil Filter 986

Engine Valve Adjustment 987

Fault Codes 988

Forks 989

Fork Pins, Carriage Pins, and Carriage Sliding Surfaces 989

Frame, Mast, Carriage and Attachment 990

Fuel, Oil, DEF, or Coolant Leaks 990

Fuel/Water Separator and Final Fuel Filter 990

Fuel Tank Breather 991

Header Hose Assembly 991

Horn, Gauges, Lights, Alarms and Control System 991

Hydraulic System Oil 992

Hydraulic Oil Testing Procedures 992

Hydraulic Oil Replacement 993

Hydraulic Tank Breather 994

Hydraulic Tank Return Filter 994

Inching Pedal Sensor Calibration 994

Lift Chains 994

Check and Lubricate Lift Chains 994

Adjust Lift Chains 995

Inspect Lift Chains 996

Chain Elongation 997

Lift Chain Wear and Damage 997

Lift System Accumulator (Optional) 998

Load Rollers 998

Carriage Load Rollers 998

Inner Mast Load Rollers 998

Mast, Carriage, and Attachment 998

Mast Pivot Pins 999

Operator Presence System 999

Operator Restraint System 999

Seat Belt and Seat Rails 999

Steering Column Latch 1000

Parking and Service Brakes 1000

Radiator Assembly 1000

Steering Axle Grease Fittings 1000

King Pins 1000

Tie Rod Pins 1001

Steering System 1001

Steering Wheel Hub Bearings 1001

Remove and Disassemble 1001

Clean and Inspect 1001

Assemble and Install 1002

Tilt Cylinder Pivot Pins 1002

Transmission 1002

Transmission Clutch Calibration 1003

Transmission Oil Level 1003

Transmission Oil and Oil Filter 1003

Vibration Damper (Viscous) 1004

Warning and Safety Labels 1004

Windows and Mirrors 1005

Windshield Washer Fluid Level 1005

Wheels and Tires 1005

Wheels, Tires, and Tire Pressure 1005

Remove Wheels from Lift Truck 1006

Adding Air Pressure to Pneumatic Tires 1012

Install Wheels on Lift Truck 1016

Capacities and Specifications 1017

Approved Fuel and Engine Oils 1017

Approved Oils, Fluids, and Grease 1018

Engine Oil Viscosity 1019

Lift Chain Lubricant Requirements 1019

Fuses and Relays 1019

Main Electrical Supply 1021

Relays 1023

550123401 8000YRM1940 (10 2016) US EN 1025

General 1029

Weight and Dimensions 1030

Loading Procedures 1038

Loading a Truck on a Transport 1038

Loading Disassembled Components 1038

Unloading Procedures 1039

Unloading a Truck From Transport 1039

Lifting a Truck 1039

Driving a Truck off a Trailer 1040

Unloading Disassembled Components 1040

Removal of Forks Attached to a Basic Truck 1040

Removal of Forks Attached to the Carriage 1042

Moving and Towing 1043

Moving a Disabled Lift Truck 1043

Precautions 1043

Towing a Lift Truck 1043

Safety Procedures When Working Near The Mast 1044

When Working Near The Mast Always 1044

Before Starting Repairs To The Hydraulic System Always 1045

Truck Assembly 1045

Mast Assembly 1045

Preparations 1045

Installing the Mast 1045

Installing the Tilt Cylinders 1047

Adjusting the Tilt Cylinders 1047

Removing the Carriage Transport Lock 1048

Connecting the Lift Cylinders 1048

Connecting the Mast Supply Hoses 1048

Carriage and Forks or Attachment 1050

Install Carriage/Attachment 1050

Connecting Hoses to Carriage/Attachment 1051

Install Forks 1051

Adjust Carriage 1052

Install Cab Lights 1053

Lubricate 1053

General Checks After Assembly 1053

Plumbing Check 1054

Lubrication Check 1054

Fluid Level Check 1054

Functionality Check 1054

Literature Package Check 1054

Cleaning 1054

Labels 1054

Wheels and Tires 1054

Remove Wheels From Lift Truck 1054

Remove Pneumatic Tire From Wheel 1056

Install Pneumatic Tire on Wheel 1058

Adding Air Pressure to the Tires 1059

Remove Solid Rubber Tire From Wheel 1060

Install Solid Rubber Tire on Wheel 1062

Install Wheels on Lift Truck 1064

Wheel Nuts on Drive and Steer Wheels 1064

Pre-Delivery 1064

Adjust Timing For Automatic Engine Shut Down 1064

Perform Pre-Delivery Inspection 1064

Delivery 1065

Instructions Operating Manual 1065

Instructions Daily Maintenance 1065

Handing Over Truck 1065

550185564 0100YRM2107 (12 2018) US EN 1069

Series Code / Model Designation Reference Table 1073

Description and Operation 1073

Heater System 1073

General 1073

Air Conditioning 1074

General 1074

Dryer 1075

Compressor Lubrication 1076

Control Systems, Sensors, and Switches 1076

Climate Control 1077

Description 1077

Service Menu 1077

Set Up 1078

View 1 and View 2 1078

Error List 1079

Statistics 1079

Exit 1079

Temperature Sensors 1079

Troubleshooting 1080

Water Valve 1080

Troubleshooting 1080

Troubleshooting 1083

Insufficient or no cooling 1083

Preliminary Checks 1083

Checking System Air Output 1083

Check The Sight Glass for Bubbles 1083

Remove and Replace 1086

Standard Heater Assembly 1086

Access 1086

Remove 1086

Install 1087

Standard Heater Parts 1088

Heater Core 1088

Remove 1088

Install 1089

Blower 1090

Remove 1090

Install 1091

Water Valve 1091

Remove 1091

Install 1092

Push/Pull Cable 1092

Water Valve Cable 1092

Remove 1092

Install 1093

Heater/Air Conditioner Assembly 1093

Remove 1093

Install 1094

Heater/Air Conditioner Parts 1095

Vent Door 1095

Remove 1095

Install 1096

Heater Core 1096

Remove 1096

Install 1097

Evaporator Core 1097

Remove 1097

Install 1099

Blower 1099

Remove 1099

Install 1100

Thermostat 1100

Remove 1100

Install 1101

Water Valve 1102

Remove 1102

Install 1103

Filtration 1103

Fresh Air Filter 1103

Remove 1103

Install 1103

Recirculation Air Filter 1103

Remove 1103

Install 1104

Air Conditioning Technical Detail 1104

Maintenance Procedures and Required Equipment 1105

Maintenance Procedures 1105

Installing Manifold Gauges 1105

Refrigerant Recovery 1107

Refrigerant Leak Check 1108

Evacuation and Dehydration 1108

General 1108

Preparation 1108

Procedure For Evacuation and DehydratingSystem (Triple Evacuation) 1108

Procedure For Evacuation and DehydratingSystem (One Time Evacuation) 1108

Adding Refrigerant to a System 1109

Checking Refrigerant Charge 1109

Adding Full Charge 1109

Adding Partial Charge 1109

Filter Drier 1110