$34.95

Yanmar 4TNE92-NMH 4TNE92-NMHA 4TNE98-NMH Series Service Manual PDF

Yanmar 4TNE92-NMH 4TNE92-NMHA 4TNE98-NMH Series Service Manual – PDF DOWNLOAD

FILE DETAILS:

Yanmar 4TNE92-NMH 4TNE92-NMHA 4TNE98-NMH Series Service Manual – PDF DOWNLOAD

Language : English

Pages : 281

Downloadable : Yes

File Type : PDF

UTILEV PN: 76000368

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Yanmar 4TNE92-NMH 4TNE92-NMHA 4TNE98-NMH Series Service Manual – PDF DOWNLOAD

Introduction 6

Yanmar Warranties 8

Yanmar Limited Warranty 10

What is Covered by this Warranty? 10

How Long is the Warranty Period? 10

What the Engine Owner Must Do: 10

To Locate an Authorized Yanmar Industrial Engine 10

Dealer or Distributor: 10

What Yanmar Will Do: 10

What is Not Covered by this Warranty? 11

Warranty Limitations: 11

Warranty Modifications: 11

Questions: 11

Customer Registration 11

Yanmar Co , Ltd Limited Emission Control 12

System Warranty – USA Only 12

Your Warranty Rights and Obligations: 12

California 12

Manufacturer’s Warranty Period: 12

Warranty Coverage: 13

Warranted Parts: 13

Exclusions: 14

Owner’s Warranty Responsibilities: 14

Safety 16

Safety Statements 16

Safety Precautions 17

Before You Operate 17

During Operation and Maintenance 17

General Service Information 30

Component Identification 32

Location of Labels 32

EPA / ARB Emission Control Regulations – USA Only 33

Emission Control Labels 33

EPA / ARB Labels 33

The 97/68/EC Directive Certified Engines 33

Engine Family 34

Function of Major Engine Components 35

Function of Cooling System Components 37

Diesel Fuel 38

Diesel Fuel Specifications 38

Additional Technical Fuel Requirements 38

Bio-Diesel Fuels 38

Filling The Fuel Tank 39

Priming the Fuel System 41

Engine Oil 43

Engine Oil Specifications 43

Service Categories 43

Definitions 43

Additional Technical Engine oil Requirements: 43

Engine Oil Viscosity 43

Checking Engine Oil 44

Adding Engine Oil 44

Engine Oil Capacity (Typical) 44

Engine Coolant 45

Engine Coolant Specifications 45

Alternative Engine Coolant 45

Additional Technical Coolant Specifications: 46

Filling Radiator With Engine Coolant 46

Engine Coolant Capacity (Typical) 47

Specifications 48

Description of Model Number 48

Engine Speed Specifications 48

Engine General Specifications 48

Principal Engine Specifications 49

4TNE92-NMH 49

4TNE92-NMHA 50

4TNE98-NMH 51

Engine Service Information 52

Engine Tuning 52

Tightening Torques for Standard Bolts and Nuts 53

Standard Torque Chart 54

Abbreviations and Symbols 55

Abbreviations 55

Symbols 55

Unit Conversions 56

Unit Prefixes 56

Prefix 56

Symbol 56

Power 56

Units of Length 56

Units of Volume 56

Units of Mass 56

Units of Force 56

Units of Torque 56

Units of Pressure 56

Units of Power 56

Units of Temperature 56

Periodic Maintenance 58

Precautions 73

The Importance of Periodic Maintenance 73

Performing Periodic Maintenance 73

Yanmar Replacement Parts 73

Required EPA / ARB Maintenance – USA Only 73

EPA / ARB Installation Requirements – USA Only 73

Tightening Fasteners 73

Standard Torque Chart 74

Periodic Maintenance Schedule 74

Periodic Maintenance Procedures 76

Daily 76

Drain Fuel Filter / Water Separator 76

Check Fuel Hoses and Engine Coolant Hoses 77

Every 250 Hours of Operation 78

Check and Clean Radiator Fins 78

Check and Adjust Cooling Fan V-belt 79

Check Battery 80

Clean Air Cleaner Element 81

Every 500 Hours of Operation 83

Replace Engine Oil and Engine Oil Filter 83

Check and Adjust the Governor Lever and Engine Speed Control 85

Every 1000 Hours of Operation 86

Adjust Intake / Exhaust Valve Clearance 86

Clean Fuel Filter / Water Separator 86

Replace Fuel Filter 88

Every 2000 Hours of Operation 91

Replace Air Cleaner Element 91

Inspect Clean and Test Fuel Injectors 91

Every 4000 Hours of Operation 92

Drain, Flush, and Re-fill the Coolant System with New Coolant 92

Replace Fuel Hoses and Engine Coolant Hoses 93

Engine 94

Engine Service Information 98

Engine Body 98

Cylinder Head 98

Intake / Exhaust Valve and Guide 98

Valve Spring 99

Rocker Arm and Shaft 99

Push Rod 99

Gear Train and Camshaft 100

Camshaft 100

Idler Gear Shaft and Bushing 100

Backlash of Each Gear 101

Cylinder Block 101

Crankshaft 101

Thrust Bearing 102

Piston 102

Piston Ring 103

Connecting Rod 103

Tappet 104

Engine Special Torque Chart 105

Special Service Tools 106

Measuring Instruments 108

Before You Begin Servicing 111

Removal of Engine 112

Cylinder Head Components 113

Disassembly of Cylinder Head 114

Removal of Glow Plugs 115

Removal of Valve Cover 115

Removal of Rocker Arm Assembly 115

Disassembly of Rocker Arm Assembly 116

Removal of Cylinder Head 116

Removal of Intake / Exhaust Valves 117

Removal of Valve Guides 117

Cleaning of Cylinder Head Components 118

Inspection of Cylinder Head Components 118

Inspection of Push Rods 118

Inspection of Rocker Arm Assembly 119

Inspection of Valve Guides 119

Inspection of Cylinder Head 119

Inspection of Intake and Exhaust Valves 119

Inspection of Valve Springs 121

Assembly of Cylinder Head 121

Assembly of Valve Guides 121

Assembly of Intake and Exhaust Valves 122

Assembly of Cylinder Head 123

Assembly of Rocker Arm Assembly 123

Assembly of the Valve Cover 124

Assembly of Glow Plugs 124

Measuring and Adjusting Valve Clearance 125

Valve Clearance Measurement 125

Valve Clearance Adjustment 126

Drive Train and Camshaft Components 127

Disassembly of Drive Train and Camshaft Components 128

Removal of Oil Pan 129

Removal of Oil Sump Pump 129

Removal of Timing Gears 129

Removal of Pistons 130

Removal of Crankshaft 131

Removal of Camshaft 132

Removal of Gear Case 133

Inspection of Drive Train and Camshaft Components 133

Inspection of Cylinder Block 133

Inspection of Pistons 137

Inspection of Piston Pin 137

Inspection of Connecting Rod 138

Inspection of Tappets 138

Inspection of Crankshaft 138

Inspection of Camshaft 139

Inspection of Camshaft Bushings 140

Inspection of Idler Gear and Shaft 140

Honing and Boring 141

Assembly of Drive Train and Camshaft Components 142

Assembly of Pistons 142

Installation of Gear Case 143

Installation of Crankshaft 143

Installation of Pistons 144

Installation of Camshaft 145

Installation of Timing Gears 145

Installation of Gear Case Cover 146

Installation of Oil Sump Pump 146

Installation of Oil Pan 146

Fuel System 148

Fuel System Special Torque Chart 150

Measuring Instruments 150

Fuel System Components 153

Fuel System Diagram 154

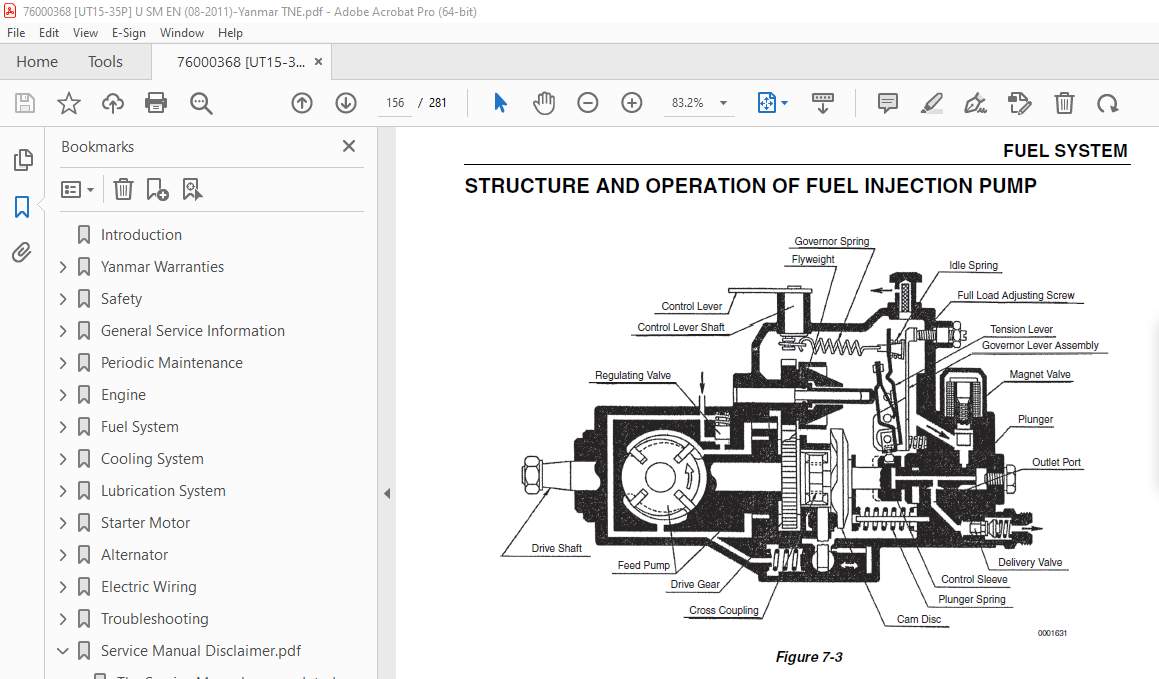

Structure and Operation of Fuel Injection Pump 156

Overview 157

Pump 157

Governor 157

Timer 158

Feed Pump (Vane Type) 158

Regulating Valve 159

Plunger Operation 160

Process 161

Suction Process 161

Injection Process 161

End of Injection 162

Uniform Pressure Process 162

Reverse Rotation Prevention Mechanism 163

Fuel Injection Volume Adjustment Mechanism 163

Delivery Valve Assembly 164

Delivery Valve Holder with Damping Valve 164

All -Speed Governor 165

At Start of Engine 167

During Idling 168

At Full-Load Maximum Speed Control 169

At No-Load Maximum Speed Control 170

Full-Load Position Adjustment Mechanism 171

Structure and Operation of Timer 172

Standard Type Automatic Timer 172

Magnetic Valve (Stop Solenoid) 173

Before You Begin Servicing 174

Removal of Fuel Injection Pump 175

Installation of the Fuel Injection Pump 178

Checking / Adjustment of Fuel Injection Timing 180

Servicing the Fuel Injectors 182

Removal of the Fuel Injectors 182

Inspection and Testing of the Fuel Injectors 183

Test Procedure Using a Nozzle Tester 183

Judgement Criteria on Atomization Condition 185

Cleaning of Nozzle 186

Installation of Fuel Injectors 186

Cooling System 188

Measuring Instruments 191

Cooling System Diagram 193

Model 4TNE92-NMHA 193

Models 4TNE92-NMH and 4TNE98-NMH 194

Engine Coolant Pump Components 195

Model 4TNE92-NMHA 195

Models 4TNE92-NMH and 4TNE98-NMH 196

Before You Begin Servicing 197

Engine Coolant System Check 198

Disassembly of Engine Coolant Pump 199

Disassembly of the 4TNE92-NMHA Coolant Pump 200

Disassembly of the 4TNE92-NMH and 4TNE98-NMH 200

Coolant Pumps 200

Cleaning and Inspection 201

Thermostat 201

Radiator Cap 201

Assembly of Engine Coolant Pump 202

Assembly of the 4TNE92-NMHA Coolant Pump 202

Assembly of the 4TNE92-NMH and 4TNE98-NMH 202

Coolant Pumps 202

Assembly of All Coolant Pump Models 203

Lubrication System 206

Oil Pump Service Information 210

Engine Oil Pressure – All Models 210

Outer Rotor Outside Clearance – All Models 210

Outer Rotor Side Clearance – All Models 210

Outer Rotor to Inner Rotor Tip Clearance – All Models 210

Rotor Shaft Clearance – All Models 210

Lubrication System Diagram 211

Checking Engine Oil Pressure 212

Oil Pump Components 212

Before You Begin Servicing 212

Disassembly of Oil Pump 214

Cleaning and Inspection 214

Check Outer Rotor Outside Clearance 215

Outer Rotor to Inner Rotor Tip Clearance 215

Check Outer Rotor Side Clearance 215

Check Rotor Shaft Clearance 215

Assembly of Oil Pump 216

Starter Motor 218

Starter Motor Service Information 222

Starter Motor Troubleshooting 223

Starter Motor Precautions 224

Starter Motor Servicing 225

Starter Motor Components 225

Before You Begin 226

Starter Motor Removal 227

Starter Motor Disassembly 227

Inspection 229

Armature 229

Field Coil 231

Brush Holder 232

Magnetic Switch 233

Pinion Clutch Assembly 234

Starter Motor Assembly 235

Check Pinion Projection Length 236

No Load Test 237

Starter Motor Installation 237

Alternator 238

Alternator Service Information 243

Alternator Troubleshooting 244

Alternator Precautions 245

Alternator Components 246

Alternator Servicing 247

Before You Begin Servicing 247

Removal of Alternator 248

Disassembly of Alternator 249

Inspection 252

Stator Coil 252

Rotor 252

Rectifier 253

IC Regulator 254

Diode 256

Brush 256

Assembly of Brush Holder 257

Assembly of Alternator 259

Installation of Alternator 260

Bench Test 261

Test Wiring 262

Regulated Voltage Check 263

No Load Test 263

Output Test 263

Electric Wiring 264

Electric Wiring Precautions 266

Electrical Wire Resistance 267

Battery Cable Resistance 268

Electrical Wire Sizes – Voltage Drop 269

Conversion of AWG to European Standards 270

Electric Wiring Diagram 271

Troubleshooting 272

Special Service Tools 274

Troubleshooting By Measuring Compression Pressure 275

Compression Pressure Measurement Method 275

Standard Compression Pressure 276

Engine Speed and Compression Pressure (Use for Reference) 276

Measured Value and Troubleshooting 277

Quick Reference Table For Troubleshooting 277

Service Manual Disclaimer pdf 0

The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the product Updated technical service information may be available from your local authorized UTILEV® distributor Service Manuals provide general guidelines for maintenance and service and are intended for use by trained and experienced technicians Failure to properly maintain equipment or to follow instructions contained in the Service Manual could result in damage to the products, personal injury, property damage or death 2