$35

Yanmar Industrial Engine 2TNV70, 3TNV70, 3TNV76 Service Manual 50940077 2009 – PDF DOWNLOAD

Yanmar Industrial Engine 2TNV70, 3TNV70, 3TNV76 Service Manual 50940077 2009 – PDF DOWNLOAD

FILE DETAILS:

Yanmar Industrial Engine 2TNV70, 3TNV70, 3TNV76 Service Manual 50940077 2009 – PDF DOWNLOAD

Language : English

Pages : 264

Downloadable : Yes

File Type : PDF

Size: 16.2 MB

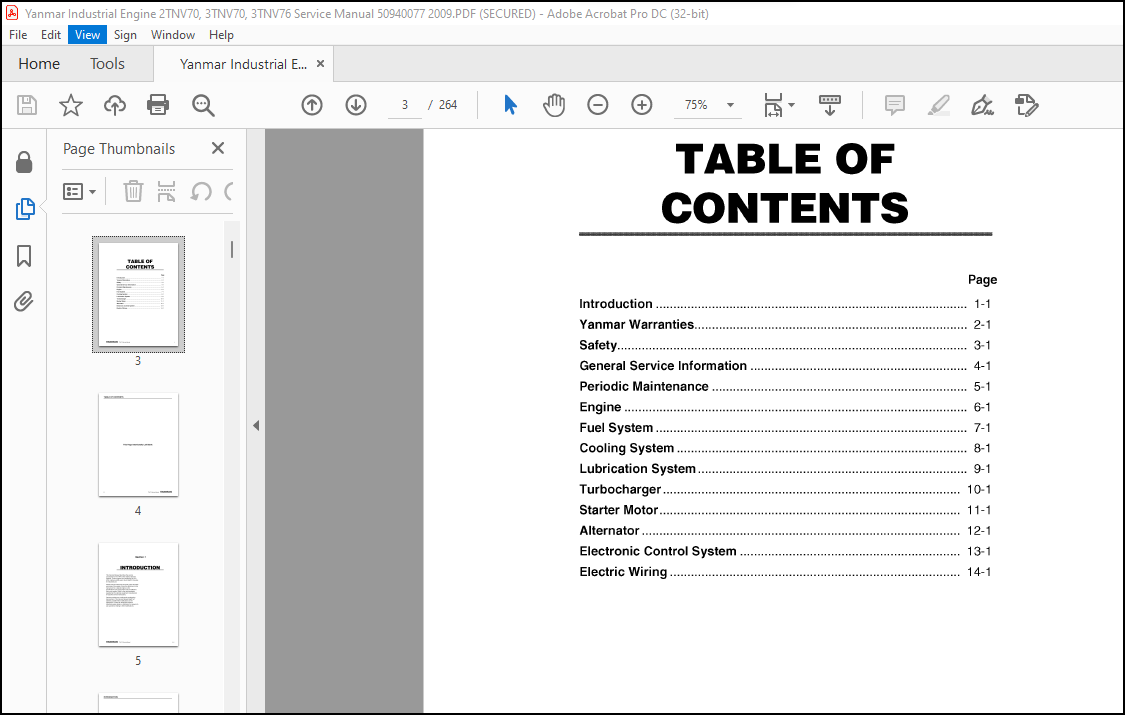

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Yanmar Industrial Engine 2TNV70, 3TNV70, 3TNV76 Service Manual 50940077 2009 – PDF DOWNLOAD

INTRODUCTION:

This Service Manual describes the service procedures for the TNV series indirect injection engines. These engines are certified by the US. EPA. California ARB and/or the 97/68/EC Directive for industrial use.

- Please use this manual for accurate, quick and safe servicing of the engine. Since the directions in this manual are for a typical engine, some specifications and components may be different from your engine. Refer to the documentation supplied by the optional equipment manuiacturer for Specific service instructions.

- Yanmar products are continuously undergoing Improvement. This Service Manual might not address possible iieid modiiications to the equipment. Contact an authorized Yanmar industrial engine dealer or distributor for answers to any questions relating to field modifications.

TABLE OF CONTENTS:

Yanmar Industrial Engine 2TNV70, 3TNV70, 3TNV76 Service Manual 50940077 2009 – PDF DOWNLOAD

Cover…………………………………………………………………… 1

Table of Contents………………………………………………………… 3

Introduction…………………………………………………………….. 5

Yanmar Warranties………………………………………………………… 7

Yanmar Limited Warranty……………………………………………….. 9

What is Covered by this Warranty?…………………………………… 9

How Long is the Warranty Period?……………………………………. 9

What the Engine Owner Must Do:……………………………………… 9

To Locate an Authorized Yanmar Industrial Engine Dealer or Distributor:…. 10

What Yanmar Will Do:………………………………………………. 10

What is Not Covered by this Warranty?……………………………….. 10

Warranty Limitations:……………………………………………… 11

Warranty Modifications:……………………………………………. 11

Questions:……………………………………………………….. 11

Retail Purchaser Registration………………………………………. 11

Emission System Warranty………………………………………………. 12

Yanmar Co., Ltd. Limited Emission Control System Warranty – USA Only……….. 12

Your Warranty Rights and Obligations:……………………………….. 12

California……………………………………………………. 12

Manufacturer’s Warranty Period:…………………………………….. 12

Warranty Coverage:………………………………………………… 13

Warranted Parts:………………………………………………….. 13

Exclusions:………………………………………………………. 14

Owner’s Warranty Responsibilities:………………………………….. 14

Safety………………………………………………………………….. 15

Safety Statements…………………………………………………….. 17

Safety Precautions……………………………………………………. 18

General Service Information……………………………………………….. 31

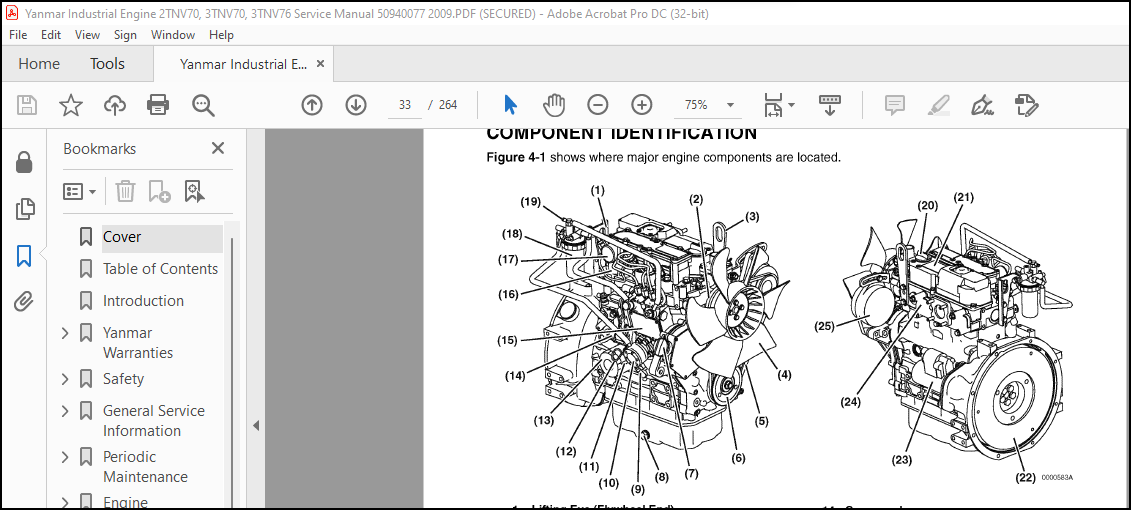

Component Identification………………………………………………. 33

Location of Labels……………………………………………………. 34

Engine Nameplate (Typical)…………………………………………. 34

EPA / ARB Emission Control Regulations – USA Only………………………… 34

Emission Control Labels……………………………………………….. 34

EPA / CARB Labels (Typical)………………………………………… 35

The 97/68/EC Directive Certified Engines………………………………… 35

Engine Family………………………………………………………… 35

Function of Major Engine Components…………………………………….. 36

Function of Cooling System Components…………………………………… 38

Diesel Fuel………………………………………………………….. 39

Diesel Fuel Specifications…………………………………………. 39

Additional Technical Fuel Requirements…………………………… 39

Bio-Diesel Fuels………………………………………………. 40

KIT PARTS LIST FOR B20 (TNV IDI Engines)…………………………. 42

Filling the Fuel Tank……………………………………………… 43

Priming the Fuel System……………………………………………. 44

Engine Oil…………………………………………………………… 45

Engine Oil Specifications………………………………………….. 45

Service Categories………………………………………………… 45

Definitions…………………………………………………… 45

Additional Technical Engine oil Requirements:…………………….. 45

Engine Oil Viscosity………………………………………………. 45

Checking Engine Oil……………………………………………….. 45

Adding Engine Oil…………………………………………………. 46

Engine Oil Capacity (Typical)………………………………………. 46

Engine Coolant……………………………………………………….. 47

Engine Coolant Specifications………………………………………. 48

Additional Technical Coolant Specifications:……………………… 48

Alternative Engine Coolant……………………………………… 48

Filling Radiator with Engine Coolant………………………………… 48

Engine Coolant Capacity (Typical)…………………………………… 49

Specifications……………………………………………………….. 50

Description of Model Number………………………………………… 50

Engine Speed Specifications………………………………………… 50

Engine General Specifications………………………………………. 51

Principal Engine Specifications………………………………………… 52

2TNV70…………………………………………………………… 52

3TNV70…………………………………………………………… 53

3TNV76…………………………………………………………… 54

Engine Service Information…………………………………………….. 55

Tightening Torques for Standard Bolts and Nuts…………………………… 56

Abbreviations and Symbols……………………………………………… 58

Abbreviations…………………………………………………….. 58

Symbols………………………………………………………….. 58

Unit Conversions……………………………………………………… 59

Unit Prefixes…………………………………………………….. 59

Units of Length…………………………………………………… 59

Units of Volume…………………………………………………… 59

Units of Mass…………………………………………………….. 59

Units of Force……………………………………………………. 59

Units of Torque…………………………………………………… 59

Units of Pressure…………………………………………………. 59

Units of Power……………………………………………………. 59

Units of Temperature………………………………………………. 59

Periodic Maintenance……………………………………………………… 61

Introduction…………………………………………………………. 63

Precautions………………………………………………………….. 64

The Importance of Periodic Maintenance………………………………. 64

Performing Periodic Maintenance…………………………………….. 64

Yanmar Replacement Parts…………………………………………… 64

Required EPA / ARB Maintenance – USA Only……………………………. 64

EPA / ARB Installation Requirements – USA Only……………………….. 64

Periodic Maintenance Schedule………………………………………….. 65

Periodic Maintenance Procedures………………………………………… 67

After Initial 50 Hours of Operation…………………………………. 67

Replace Engine Oil and Engine Oil Filter…………………………. 67

Check and Adjust Cooling Fan V-Belt……………………………… 69

Every 50 Hours of Operation………………………………………… 70

Drain Fuel Filter / Water Separator……………………………… 70

Check Battery…………………………………………………. 72

Every 250 Hours of Operation……………………………………….. 73

Drain Fuel Tank……………………………………………….. 73

Replace Engine Oil and Engine Oil Filter…………………………. 74

Check and Clean Radiator Fins…………………………………… 75

Check and Adjust Cooling Fan V-Belt……………………………… 75

Check and Adjust the Governor Lever and Engine Speed Control……….. 75

Clean Air Cleaner Element………………………………………. 76

Every 500 Hours of Operation……………………………………….. 78

Replace Air Cleaner Element…………………………………….. 78

Replace Fuel Filter……………………………………………. 78

Clean Fuel Filter / Water Separator……………………………… 80

Every 1000 Hours of Operation………………………………………. 81

Drain, Flush and Refill Cooling System with New Coolant……………. 81

Adjust Intake / Exhaust Valve Clearance………………………….. 83

Every 1500 Hours of Operation………………………………………. 83

Inspect, Clean and Test Fuel Injectors…………………………… 83

Inspect Crankcase Breather System……………………………….. 84

Every 2000 Hours of Operation………………………………………. 85

Check and Replace Fuel Hoses and Engine Coolant Hoses……………… 85

Lap the Intake and Exhaust Valves……………………………….. 85

Engine………………………………………………………………….. 87

Before You Begin Servicing…………………………………………….. 89

Introduction…………………………………………………………. 90

Cylinder Head Specifications…………………………………………… 90

Adjustment Specifications………………………………………….. 90

Cylinder Head…………………………………………………….. 90

Intake / Exhaust Valve and Guide……………………………………. 91

Push Rod…………………………………………………………. 91

Valve Spring……………………………………………………… 91

Rocker Arm and Shaft………………………………………………. 92

Camshaft and Timing Gear Train Specifications……………………………. 92

Camshaft…………………………………………………………. 92

Idler Gear Shaft and Bushing……………………………………….. 93

Timing Gear Backlash………………………………………………. 93

Crankshaft and Pistons Specifications…………………………………… 93

Crankshaft……………………………………………………….. 93

Crankshaft Reconditioning………………………………………….. 94

Thrust Bearing……………………………………………………. 94

Piston…………………………………………………………… 95

Piston Ring………………………………………………………. 96

Connecting Rod……………………………………………………. 97

Connecting Rod Small End……………………………………….. 97

Connecting Rod Big End…………………………………………. 98

Connecting Rod Distortion………………………………………. 98

Tappet…………………………………………………………… 98

Cylinder Block Specifications………………………………………….. 98

Cylinder Block……………………………………………………. 98

Special Torque Chart………………………………………………….. 99

Torque for Bolts and Nuts………………………………………….. 99

Special Service Tools………………………………………………….100

Measuring Instruments………………………………………………….102

Cylinder Head…………………………………………………………104

Cylinder Head Components……………………………………………104

Disassembly of Cylinder Head………………………………………..105

Removal of Intake Manifold / Valve Cover………………………….106

Removal of Glow Plugs…………………………………………..106

Removal of Rocker Arm Assembly…………………………………..106

Disassembly of Rocker Arm Assembly……………………………….107

Removal of Cylinder Head………………………………………..107

Removal of Intake / Exhaust Valves……………………………….108

Removal of Valve Guides…………………………………………108

Cleaning of Cylinder Head Components…………………………………109

Inspection of Cylinder Head Components……………………………….109

Inspection of Push Rods…………………………………………109

Inspection of Rocker Arm Assembly………………………………..110

Inspection of Valve Guides………………………………………110

Inspection of Cylinder Head……………………………………..110

Inspection of Intake and Exhaust Valves…………………………..111

Inspection of Valve Springs……………………………………..112

Reassembly of Cylinder Head…………………………………………113

Reassembly of Valve Guides………………………………………113

Reassembly of Intake and Exhaust Valves…………………………..114

Reassembly of Cylinder Head……………………………………..115

Reassembly of Rocker Arm Assembly………………………………..116

Reassembly of Intake Manifold / Valve Cover……………………….117

Measuring and Adjusting Valve Clearance………………………………118

3-Cylinder Engines……………………………………………..118

Cylinder Block………………………………………………………..120

Crankshaft and Camshaft Components…………………………………..120

Disassembly of Cylinder Block Components……………………………..121

Disassembly of Camshaft and Timing Components…………………………122

Removal of Timing Gear Case Cover………………………………..122

Checking Timing Gear Backlash……………………………………122

Measuring Idler Gear-to-Crankshaft Gear Backlash…………………..123

Measuring Idler Gear-to-Camshaft Gear Backlash…………………….123

Removal of Timing Gears…………………………………………123

Removal of Oil Pan……………………………………………..124

Removal of Camshaft…………………………………………….125

Removal of Gear Case……………………………………………126

Disassembly of Crankshaft and Piston Components……………………….126

Removal of Pistons……………………………………………..126

Removal of Crankshaft…………………………………………..128

Inspection of Crankshaft and Camshaft Components………………………130

Replacement of Crankshaft Oil Seals………………………………130

Crankshaft Bearing Oil Clearance…………………………………131

Inspection of Cylinder Block…………………………………….131

Inspection of Pistons, Piston Rings and Wrist Pin………………….132

Inspection of Connecting Rod…………………………………….133

Inspection of Tappets…………………………………………..134

Inspection of Crankshaft………………………………………..135

Reconditioning the Crankshaft……………………………………….135

Inspection of Camshaft………………………………………….136

Inspection of Camshaft Bushing and Bores………………………….137

Inspection of Idler Gear and Shaft……………………………….137

Honing and Boring………………………………………………….137

Reassembly of Crankshaft and Piston Components………………………..138

Reassembly of Pistons…………………………………………..139

Installation of Crankshaft………………………………………141

Installation of Pistons…………………………………………142

Reassembly of Camshaft and Timing Components………………………….144

Installation of Gear Case……………………………………….144

Installation of Camshaft………………………………………..144

Installation of Timing Gears…………………………………….145

Installation of Gear Case Cover………………………………….145

Installation of Oil Pan…………………………………………146

Final Assembly of Engine………………………………………..146

Fuel System………………………………………………………………147

Before You Begin Servicing……………………………………………..149

Introduction………………………………………………………….150

Fuel Injection Pump………………………………………………..150

Stop Solenoid……………………………………………………..151

Fuel System Specifications……………………………………………..152

Special Torque Chart……………………………………………….152

Test and Adjustment Specifications…………………………………..152

Special Service Tools………………………………………………….153

Measuring Instruments………………………………………………….153

Fuel System Diagram……………………………………………………154

Fuel System Components…………………………………………………155

Fuel Injection Lines…………………………………………………..156

Removal of High-Pressure Fuel Injection Lines…………………………156

Installation of High-Pressure Fuel Injection Lines…………………….157

Removal of Fuel Return Line…………………………………………157

Installation of Fuel Return Line…………………………………….158

Fuel Injection Pump……………………………………………………158

Removal of Fuel Injection Pump………………………………………158

Installation of Fuel Injection Pump………………………………….161

Checking and Adjusting Fuel Injection Timing……………………………..164

Checking Fuel Injection Timing………………………………………164

Adjusting Fuel Injection Timing……………………………………..168

Fuel Injectors………………………………………………………..168

Removal of Fuel Injectors…………………………………………..168

Testing of Fuel Injectors…………………………………………..169

Fuel Injector Test Results………………………………………171

Disassembly and Inspection of Fuel Injectors………………………….172

Adjusting Fuel Injector Pressure…………………………………….173

Reassembly of Fuel Injectors………………………………………..174

Installation of the Fuel Injectors…………………………………..174

Cooling System……………………………………………………………175

Before You Begin Servicing……………………………………………..177

Introduction………………………………………………………….178

Cooling System Diagram…………………………………………………178

Engine Coolant Pump Components………………………………………….179

Engine Coolant System Check…………………………………………….180

Engine Coolant Pump……………………………………………………180

Disassembly of Engine Coolant Pump…………………………………..180

Cleaning and Inspection…………………………………………….181

Temperature Switch……………………………………………..181

Thermostat…………………………………………………….181

Radiator Cap…………………………………………………..181

Reassembly of Engine Coolant Pump……………………………………182

Lubrication System………………………………………………………..185

Before You Begin Servicing……………………………………………..187

Introduction………………………………………………………….188

Oil Pump Service Information……………………………………………188

Engine Oil Pressure………………………………………………..188

Outer Rotor Outside Clearance……………………………………….188

Outer Rotor Side Clearance………………………………………….188

Outer Rotor to Inner Rotor Tip Clearance……………………………..188

Inner Rotor and Gear Boss Clearance………………………………….189

Lubrication System Diagram……………………………………………..190

Checking Engine Oil Pressure……………………………………………191

Trochoid Oil Pump……………………………………………………..191

Oil Pump Components………………………………………………..191

Disassembly of Oil Pump…………………………………………….192

Cleaning and Inspection…………………………………………….193

Check Outer Rotor Outside Clearance………………………………193

Outer Rotor to Inner Rotor Tip Clearance………………………….193

Check Outer Rotor Side Clearance…………………………………193

Check Inner Rotor and Gear Boss Clearance…………………………194

Reassembly of Oil Pump……………………………………………..194

Starter Motor…………………………………………………………….195

Before You Begin Servicing……………………………………………..197

Introduction………………………………………………………….198

Starter Motor Information………………………………………………198

Starter Motor Specifications……………………………………………199

Starter Motor Troubleshooting…………………………………………..200

Starter Motor Components……………………………………………….201

Starter Motor…………………………………………………………202

Removal of Starter Motor……………………………………………203

Disassembly of Starter Motor………………………………………..203

Cleaning and Inspection…………………………………………….205

Armature………………………………………………………205

Field Coil…………………………………………………….207

Brush Holder…………………………………………………..208

Solenoid Switch………………………………………………..208

Pinion Clutch Assembly………………………………………….209

Reassembly of Starter Motor…………………………………………210

Check Pinion Projection Length………………………………………212

No-Load Test………………………………………………………212

Installation of Starter Motor……………………………………….213

Alternator……………………………………………………………….215

Before You Begin Servicing……………………………………………..217

Introduction………………………………………………………….218

Standard and Optional Dynamo Information…………………………………218

Standard and Optional Alternator Information……………………………..218

Alternator Specifications………………………………………………218

Dynamo Specifications………………………………………………….219

Alternator Troubleshooting……………………………………………..220

Alternator Components………………………………………………….221

Alternator Wiring Diagram………………………………………………222

Alternator Standard Output……………………………………………..223

Alternator……………………………………………………………224

Removal of Alternator………………………………………………224

Disassembly of Alternator…………………………………………..224

Reassembly of Alternator……………………………………………226

Installation of Alternator………………………………………….228

Dynamo Component Location………………………………………………229

Dynamo Wiring Diagram………………………………………………….230

Operation of Dynamo……………………………………………………230

Dynamo Standard Output…………………………………………………231

Testing of Dynamo……………………………………………………..232

Testing Stator Coil Continuity………………………………………232

Testing Stator Coil Short-to-Ground………………………………….232

Testing Dynamo Regulated Output……………………………………..232

Dynamo……………………………………………………………….232

Removal of Dynamo………………………………………………….232

Disassembly of Dynamo………………………………………………233

Reassembly of Dynamo……………………………………………….233

Installation of Dynamo……………………………………………..234

Electric Wiring…………………………………………………………..235

Electric Wiring Precautions…………………………………………….237

Electric Wire Resistance……………………………………………….238

Battery Cable Resistance……………………………………………….239

Electrical Wire Sizes – Voltage Drop…………………………………….240

Conversion of AWG to European Standards………………………………….241

Troubleshooting…………………………………………………………..243

Special Service Tools………………………………………………….245

Troubleshooting By Measuring Compression Pressure…………………………246

Compression Pressure Measurement Method………………………………246

Standard Compression Pressure……………………………………….247

Engine Speed and Compression Pressure (Use for Reference)………………247

Measured Value and Troubleshooting…………………………………..248

Quick Reference Table For Troubleshooting………………………………..248

Troubleshooting Charts……………………………………………..249

Electric Wiring……………………………………………………….261

Back Cover……………………………………………………………….264