$35

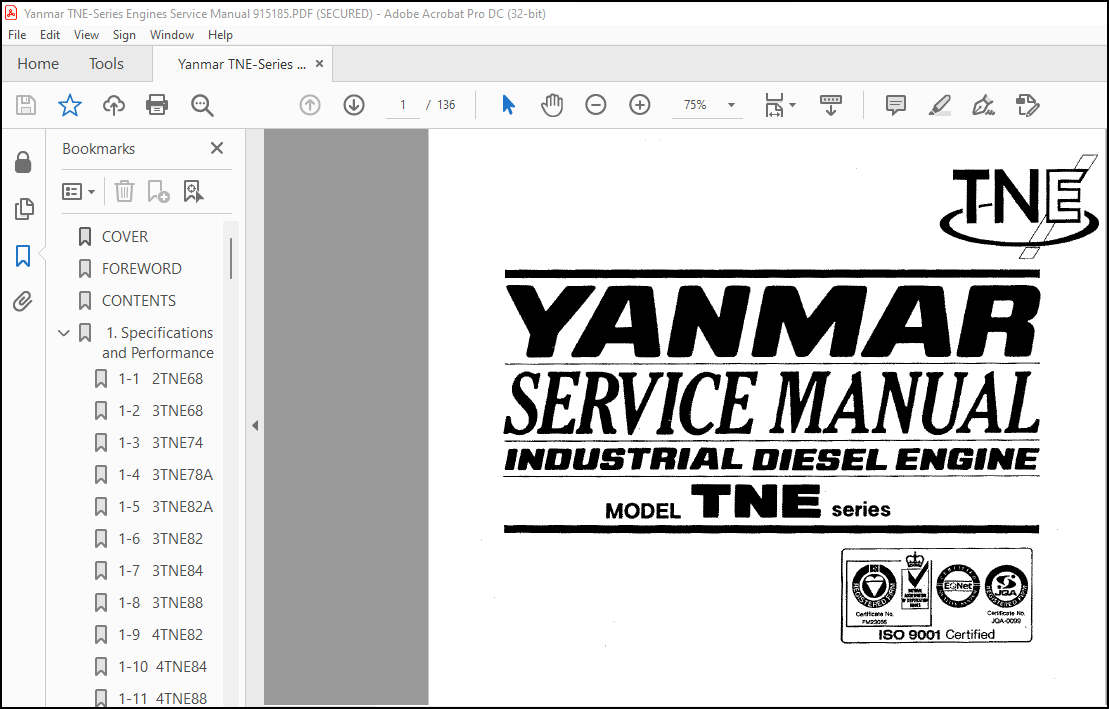

Yanmar TNE-Series Engines Service Manual 915185 – PDF DOWNLOAD

Yanmar TNE-Series Engines Service Manual 915185 – PDF DOWNLOAD

FILE DETAILS:

Yanmar TNE-Series Engines Service Manual 915185 – PDF DOWNLOAD

Language : English

Pages : 136

Downloadable : Yes

File Type : PDF

Size: 4.01 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Yanmar TNE-Series Engines Service Manual 915185 – PDF DOWNLOAD

FOREWORD:

This Service Manual describes the procedure of maintenance and service of the Yanmar industrial

TNE series engine (Special swirl precombustion chamber (hereinafter “Indirect injection system”)

and Direct injection systems).

- Before starting service and maintenance of TNE engine, you are requested to read this Service

Manual carefully to your full understanding and to take careful note that the standard TNE engine

may differ in the structure and applicable specification from that loaded on each of individual driven

machines (such as the generator, pump, compressor, and combine, etc. ). - For further information, carefully read the Service Manual issued for each driven machine. _

This Service Manual in subject to changes, with or without notice, with respect to the structure and

the content of maintenance for the purpose of improving engine quality.

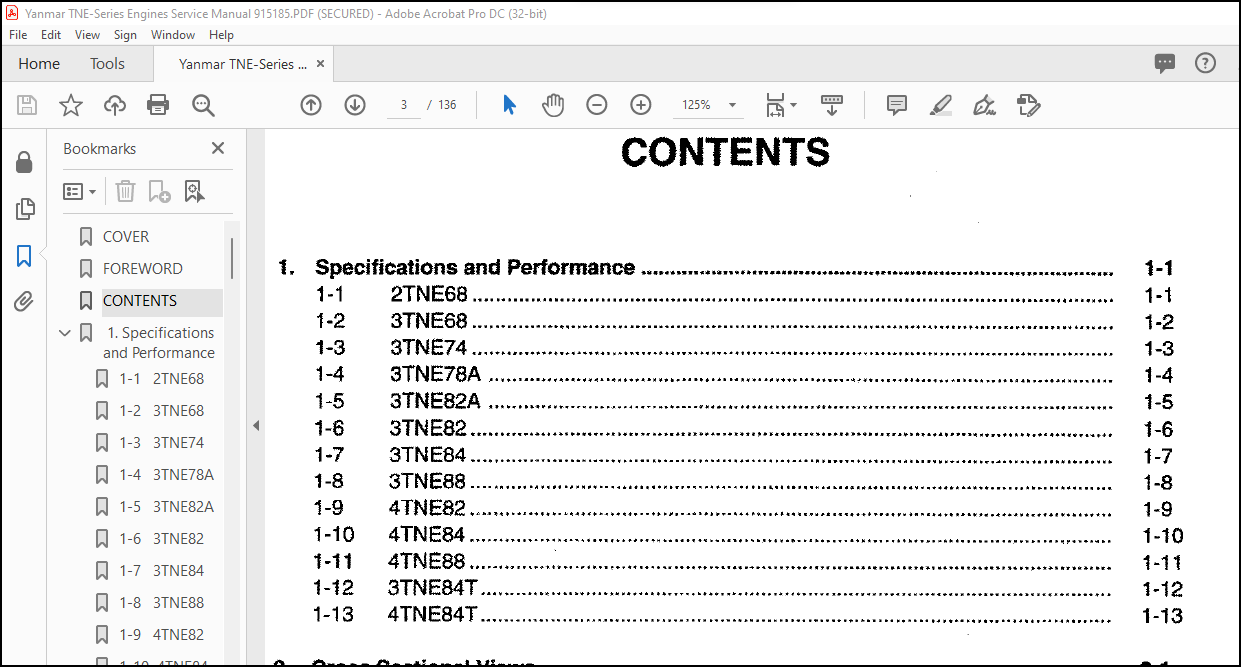

TABLE OF CONTENTS:

Yanmar TNE-Series Engines Service Manual 915185 – PDF DOWNLOAD

COVER……………………………………………………………………………………….. 1

FOREWORD…………………………………………………………………………………….. 2

CONTENTS…………………………………………………………………………………….. 3

1. Specifications and Performance……………………………………………………………… 7

1-1 2TNE68……………………………………………………………………………… 7

1-2 3TNE68……………………………………………………………………………… 8

1-3 3TNE74……………………………………………………………………………… 9

1-4 3TNE78A…………………………………………………………………………….. 10

1-5 3TNE82A…………………………………………………………………………….. 11

1-6 3TNE82……………………………………………………………………………… 12

1-7 3TNE84……………………………………………………………………………… 13

1-8 3TNE88……………………………………………………………………………… 14

1-9 4TNE82……………………………………………………………………………… 15

1-10 4TNE84……………………………………………………………………………… 16

1-11 4TNE88……………………………………………………………………………… 17

1-12 3TNE84T…………………………………………………………………………….. 18

1-13 4TNE84T…………………………………………………………………………….. 19

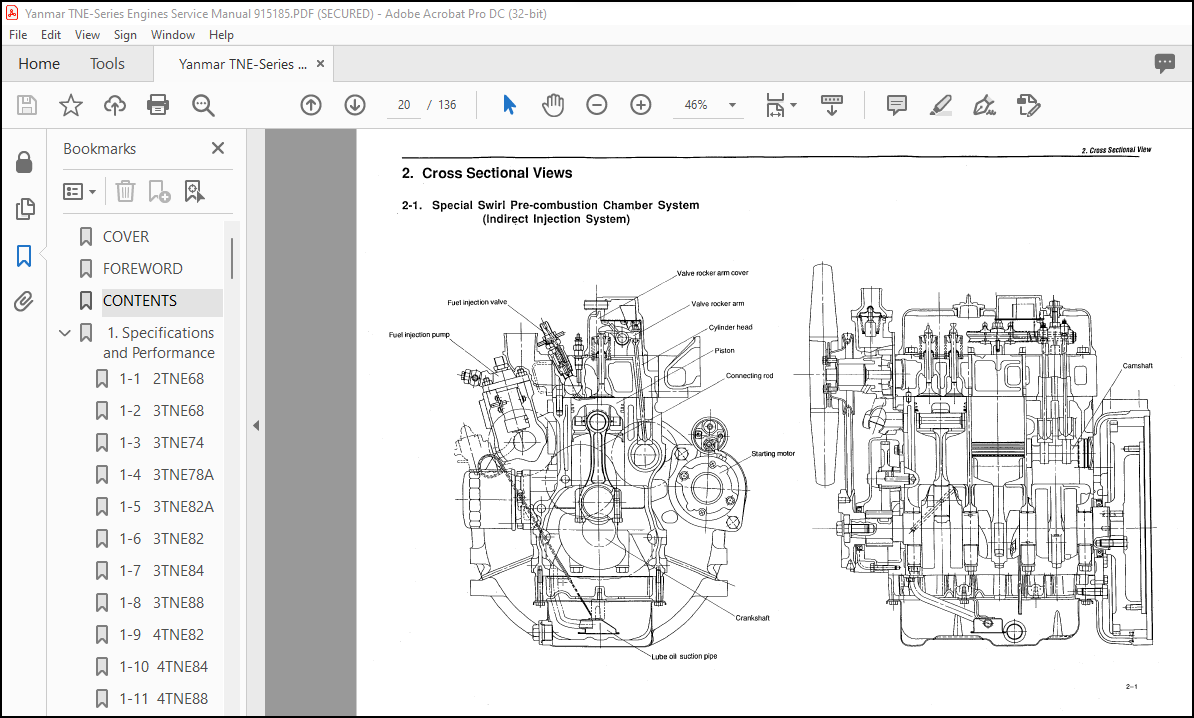

2. Cross Sectional Views……………………………………………………………………… 20

2-1 Special Swirl Pre-combustion Chamber System…………………………………………….. 20

2-2 Direct Injection System………………………………………………………………. 21

3. Cooling Water,Lubricating Oil and Fuel Oil…………………………………………………… 22

3-1 Cooling water……………………………………………………………………….. 22

3-2 Lubricating oil……………………………………………………………………… 22

3-3 Fuel oil……………………………………………………………………………. 24

4. Troubleshooting…………………………………………………………………………… 25

4-1 Trouble causes and remedies…………………………………………………………… 25

4-2 Trouble diagnousis through measurement of compression pressure……………………………. 27

5. Special Service Tools and Measuring Instruments………………………………………………. 28

5-1 Special service tools………………………………………………………………… 28

5-2 Measuring instruments………………………………………………………………… 30

6. Measurement,Inspection and Adjustment……………………………………………………….. 33

6-1 Measuring the compression pressure…………………………………………………….. 33

6-2 Adjusting the valve head clearance…………………………………………………….. 35

6-3 Checking the V-belt tension…………………………………………………………… 36

6-4 Measuring and checking the injection pressure and spray patterns of the fuel injection valve…. 36

6-5 Checking and adjusting the fuel injection timing………………………………………… 40

6-6 Adjusting the no-load maximum(or minimum)revolutions…………………………………….. 42

6-7 Checking the cooling water system and radiator for water leakage………………………….. 42

6-8 Checking the battery…………………………………………………………………. 43

6-9 Checking sensors…………………………………………………………………….. 45

6-10 Checking the oil cooler………………………………………………………………. 46

6-11 Checking the piston cooling nozzle…………………………………………………….. 47

7. Measuring Procedures,Service Data and Corrective Action……………………………………….. 48

7-1 Cylinder head……………………………………………………………………….. 48

7-2 Cylinder block………………………………………………………………………. 54

7-3 Valve rocker arm…………………………………………………………………….. 57

7-4 Piston and piston ring……………………………………………………………….. 59

7-5 Connecting rod………………………………………………………………………. 64

7-6 Camshaft……………………………………………………………………………. 67

7-7 Crankshaft………………………………………………………………………….. 69

7-8 Gears………………………………………………………………………………. 72

7-9 Trochoid pump……………………………………………………………………….. 74

8. Disassembly and Reassembly…………………………………………………………………. 75

8-1 Disassembly…………………………………………………………………………. 75

8-2 Precautions before and during reassembly……………………………………………….. 80

9. Service Data……………………………………………………………………………… 84

9-1 Cylinder head……………………………………………………………………….. 84

9-2 Cylinder block………………………………………………………………………. 85

9-3 Valve rocker arm…………………………………………………………………….. 85

9-4 Piston……………………………………………………………………………… 86

9-5 Piston ring…………………………………………………………………………. 87

9-6 Connecting rod………………………………………………………………………. 88

9-7 Camshaft……………………………………………………………………………. 88

9-8 Crankshaft………………………………………………………………………….. 88

9-9 Side gap and backlash………………………………………………………………… 89

9-10 Others……………………………………………………………………………… 89

10. Tightening Torque…………………………………………………………………………. 90

10-1 Main bolt/nut……………………………………………………………………….. 90

10-2 Standard bolt and nut………………………………………………………………… 90

11. Fuel Injection Pump for Indirect Injection System…………………………………………….. 91

11-1 Exploded views(YPFR type)…………………………………………………………….. 91

11-2 Disassembly…………………………………………………………………………. 92

11-3 Inspection………………………………………………………………………….. 93

11-4 Reassembly………………………………………………………………………….. 95

12. Fuel Injection Pump for Direct Injection System………………………………………………. 96

12-1 Exploded Views(YPES type)…………………………………………………………….. 96

12-2 Special service tools for disassembly and reassembly…………………………………….. 97

12-3 Disassembly…………………………………………………………………………. 98

12-4 Inspection…………………………………………………………………………..102

12-5 Reassembly…………………………………………………………………………..104

13. Governor………………………………………………………………………………….109

13-1 Exploded views of governor for indirect injection system………………………………….109

13-2 Exploded views of governor for direct injection system……………………………………110

13-3 Disassembly………………………………………………………………………….111

13-4 Inspection…………………………………………………………………………..115

13-5 Reassembly…………………………………………………………………………..117

14. Turbocharger………………………………………………………………………………121

14-1 Specifications……………………………………………………………………….121

14-2 Construction…………………………………………………………………………121

14-3 Waste gate valve adjusting method………………………………………………………123

14-4 Exploded view of Turbocharger(w/waste gate)……………………………………………..125

14-5 Tightening torque…………………………………………………………………….126

14-6 Service standards…………………………………………………………………….126

15. Service information for CARB ULG regulation…………………………………………………..127

15-1 Emission control labels……………………………………………………………….127

15-2 Limiting the high idle and low idle adjustment screw……………………………………..132

15-3 Limiting the fuel volume limiter screw………………………………………………….133

Attached Drawing 1. Exploded Views of Engine Components……………………………………………134

Attached Drawing 2. Exploded Views of Engine Components……………………………………………135