$31

ZF Planetary Axle AP-R 715 Repair Manual 918363 – PDF DOWNLOAD

ZF Planetary Axle AP-R 715 Repair Manual 918363 – PDF DOWNLOAD

FILE DETAILS:

ZF Planetary Axle AP-R 715 Repair Manual 918363 – PDF DOWNLOAD

Language : English

Pages : 130

Downloadable : Yes

File Type : PDF

Size: 10.9 MB

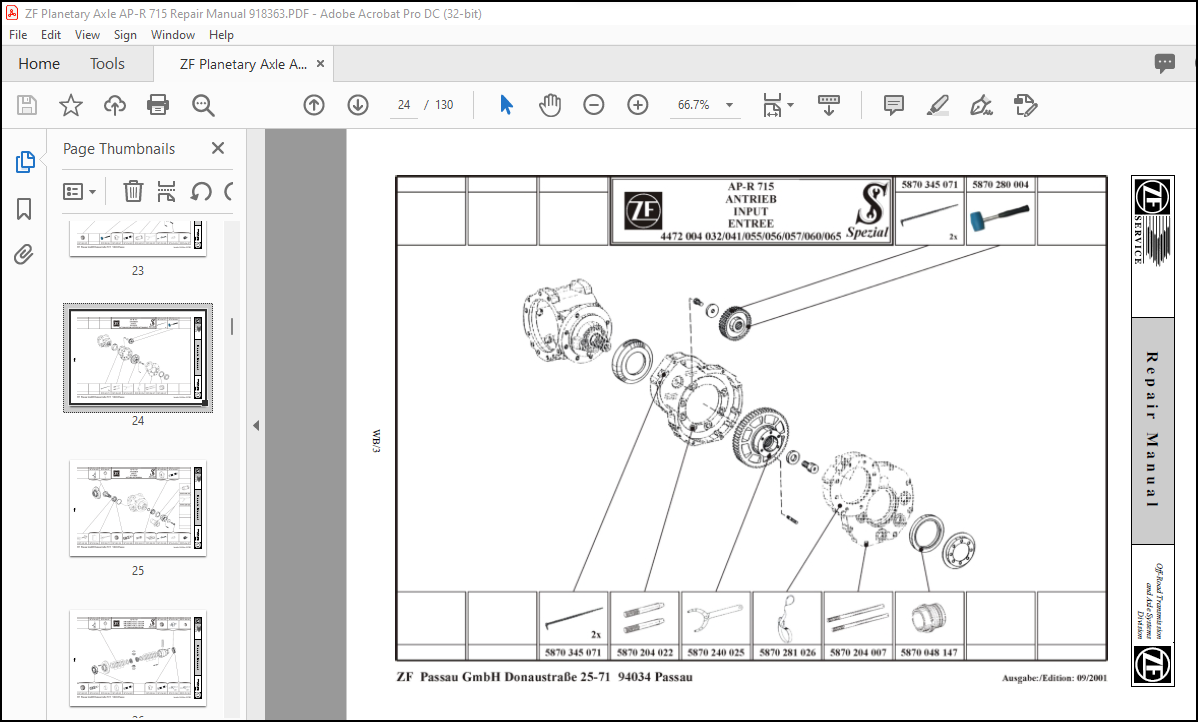

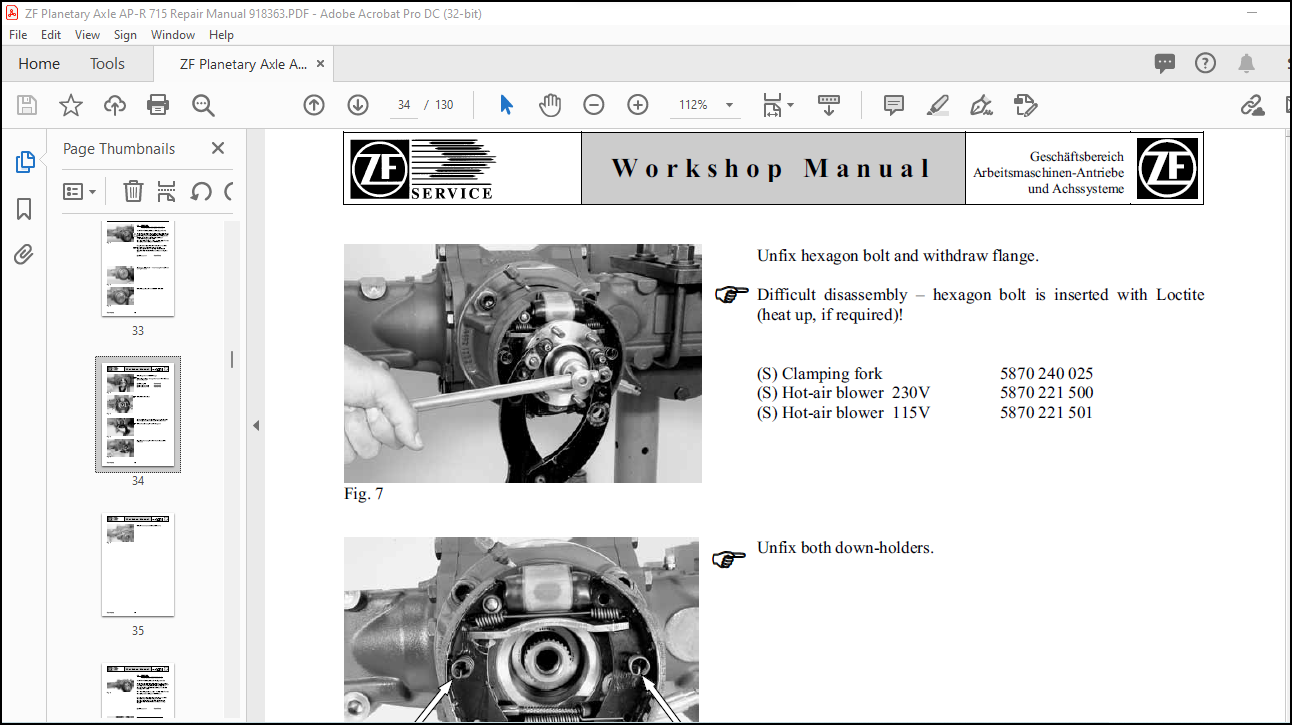

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

ZF Planetary Axle AP-R 715 Repair Manual 918363 – PDF DOWNLOAD

GENERAL:

- The Service Manual covers all works required for the disassembly and the pertaining assembly.

When repairing the transmission, ensure utmost cleanliness and that the works are carried out in an expertlike

manner. The transmission should only be disassembled for renewing damaged parts. Covers and

housing parts installed with seals must be loosened by slight blows with a plastic mallet after screws and

nuts have been removed. For removing parts being in tight contact with the shaft such as antifriction

bearings, bearing races and similar, use suitable pulling devices. - Disassembly and assembly works must be performed at a clean working place. Use the special tools

developed for that purpose. Prior to installing again the parts, clean the contact surfaces of housing and

covers from old sealing residues. Possibly formed burrs or similar irregularities must be removed with an oil

stone. Housing and cover must be cleaned with a suitable detergent, in particular in the corners. Parts which

are damaged or heavily worn down must be renewed. Here, an expert must assess, whether parts such as

antifriction bearings, stop discs etc., which are subjected to normal wear during operation, can be reused. - Parts such as sealing rings, retaining plates, split pins etc. must generally be renewed. Radial sealing rings

with worn down or torn sealing lip must also be renewed. Particularly make sure that no chips or other

foreign bodies remain in the housing. Lubricating oil bores and grooves must be checked for unhindered

passage. - Prior to their installation, all bearings must be treated with service oil.

TABLE OF CONTENTS:

ZF Planetary Axle AP-R 715 Repair Manual 918363 – PDF DOWNLOAD

ZF-PLANETARY AXLE AP-R 715…………………………………………………………………………………………………… 0

Preface………………………………………………………………………………………………………………… 3

General and important information concerning the work safety…………………………………………………………………. 4

Lubrication- and maintenance instructions………………………………………………………………………………….. 6

Technical data and settings………………………………………………………………………………………………. 8

Examples of gear-tooth contact patterns for the Gleason gear-tooth system……………………………………………………… 9

Lettering of the type plate and information for spare parts ordering………………………………………………………….. 11

Conversion table………………………………………………………………………………………………………… 12

Denomination of standard dimensions……………………………………………………………………………………….. 13

Torque limits for screws…………………………………………………………………………………………………. 14

List of special tools……………………………………………………………………………………………………. 15

Tools tables……………………………………………………………………………………………………………. 22

1. Axle versions………………………………………………………………………………………………………… 32

1.1 Version Stanard………………………………………………………………………………………………….. 32

1.2 Version “with” hydr. SIMPLEX-BRAKE…………………………………………………………………………………. 33

1.3 Version “with hydr. SERVO-BRAKE……………………………………………………………………………………. 36

1.4 Version “with B HF – BRAKE………………………………………………………………………………………… 39

1.5 Version “with” 1 Axle transmission case-150…………………………………………………………………………. 45

2. Output………………………………………………………………………………………………………………. 49

3. Differential/input pinion……………………………………………………………………………………………… 53

3.1 Differential…………………………………………………………………………………………………….. 53

3.1.1 Version “DZ 250” or “D 250″………………………………………………………………………………….. 55

3.1.2 Version “DHK” (hydr. 100% lock)………………………………………………………………………………. 57

3.2 Input pinion…………………………………………………………………………………………………….. 59

4. Differential/input pinion……………………………………………………………………………………………… 61

4.1 Differential…………………………………………………………………………………………………….. 61

4.1.1 Version “DZ 250” or “D 250″………………………………………………………………………………….. 61

4.1.2 Version “DHK”………………………………………………………………………………………………. 64

4.1.3 Determinig the adjusting spacer for the backlash/bevel gear set and bearing rolling moment of the differential bearing…. 67

4.2 Input pinion…………………………………………………………………………………………………….. 70

4.2.1 Determining the adjusting spacer for an ideal contact of the bevel gear set……………………………………….. 70

4.2.1.1 Version “without” specification of the machining dimension…………………………………………………. 70

4.2.2.1 Version “with” specification of the machining dimension……………………………………………………. 72

4.2.2 Setting the rolling moment of the input pinion bearing………………………………………………………….. 73

4.3 Checking backlash and contact pattern of the bevel gear set…………………………………………………………… 75

4.4 Mounting locking slide (100% lock)…………………………………………………………………………………. 77

4.4.1 Check function and tightness of the 100% lock………………………………………………………………….. 78

4.5 Shaft sealing ring/input flange……………………………………………………………………………………. 79

5. Output………………………………………………………………………………………………………………. 81

5.1 Hub…………………………………………………………………………………………………………….. 81

5.2 Internal gear……………………………………………………………………………………………………. 82

5.2.1 Setting the axial play of the sun gear shaft…………………………………………………………………… 84

6. Axle version “with” flange brake or axle transmission case………………………………………………………………… 86

6.1 Version “with” hydr. SIMPLEX-BRAKE…………………………………………………………………………………. 86

6.1.1 Hydr. Simplex-Brake (Functioning-and maintenance instructions)…………………………………………………… 90

6.2 Version “with” Hydr. SERVO-BRAKE…………………………………………………………………………………… 95

6.2.1 Hydr. Servo-Brake (Functioning- and maintenance instructions……………………………………………………..100

6.3 Version “with” Hydr. BHF-BRAKE……………………………………………………………………………………..109

6.3.1 Information on displacing or emergency towing of the vehicle……………………………………………………..123

6.3.2 Brake lining – wear measurement……………………………………………………………………………….125

6.4 Version “with” 1 axle transmission case-150………………………………………………………………………….126